Carbon nanotube polymer lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and carbon nanotubes, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as structural instability, achieve the effects of reducing decomposition, increasing residual capacity, and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

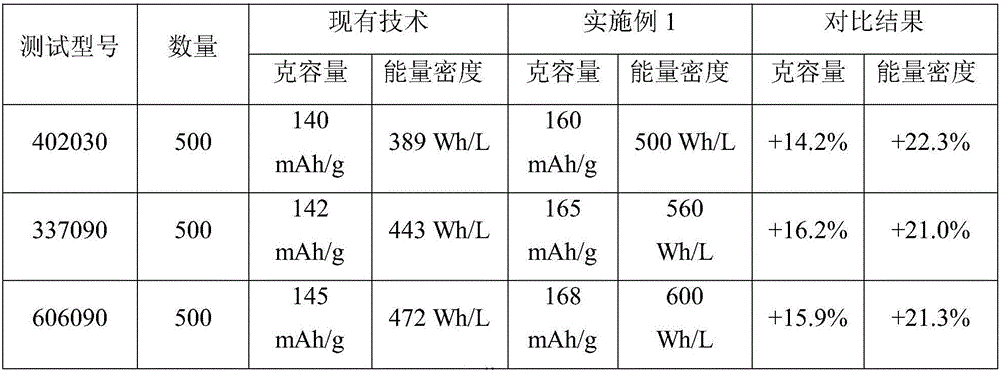

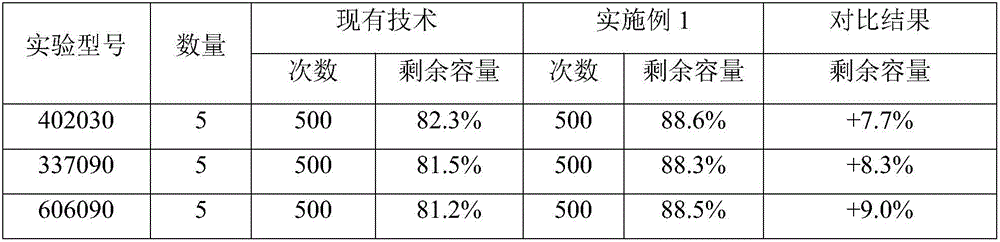

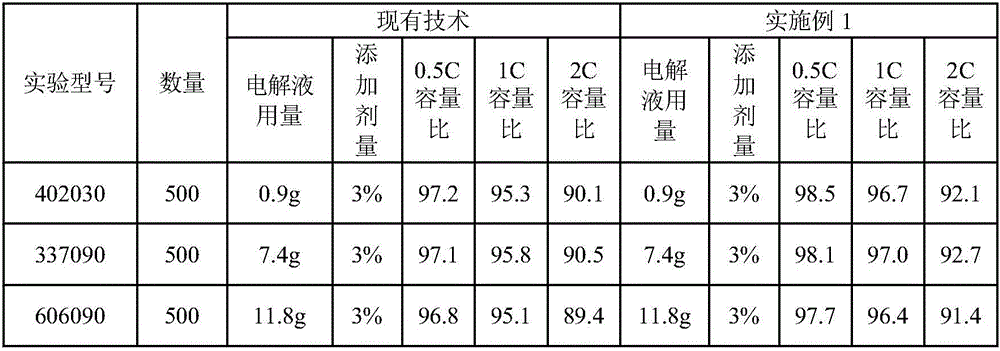

Examples

Embodiment 1

[0035] Embodiment 1 A kind of carbon nanotube polymer lithium ion battery and preparation method thereof

[0036] A carbon nanotube polymer lithium ion battery of the present embodiment, in terms of mass percentage, the active material of the positive electrode of the lithium ion battery consists of lithium cobaltate coated with 55% carbon nanometers and nickel cobalt coated with 45% carbon nanometers Lithium manganese oxide is prepared; the electrolyte of the lithium-ion battery is an organic carbonate containing additives, and the additives are EC, PC-51a and EMC with a mass ratio of 1:1:1; the additives are in the electrolyte The amount in is 3%.

[0037] The preparation method of the carbon nanotube polymer lithium ion battery of the present embodiment comprises the following steps:

[0038] (1) Using NMP as a solvent, add polyvinylidene fluoride PVDF and stir for 1.5 hours, then add positive electrode active material and superconducting carbon nanotubes CNT and stir for ...

Embodiment 2

[0043] Embodiment 2 A kind of carbon nanotube polymer lithium ion battery and preparation method thereof

[0044] The active material of the anode of a kind of carbon nanotube polymer lithium ion battery of the present embodiment is identical with embodiment 1; The composition of the electrolyte of described lithium ion battery is identical with embodiment 1; The amount is 5%.

[0045] The preparation method of the carbon nanotube polymer lithium ion battery of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0046] Embodiment 3 A kind of carbon nanotube polymer lithium ion battery and preparation method thereof

[0047] A carbon nanotube polymer lithium ion battery of the present embodiment, in terms of mass percentage, the active material of the positive electrode of the lithium ion battery consists of lithium cobalt oxide coated with 50% carbon nanometers and nickel cobalt coated with 50% carbon nanometers Lithium manganate is prepared; the electrolyte of the lithium-ion battery is a room temperature ionic liquid containing additives, and the additives are DMC, VC, and DEC with a mass ratio of 1:1:1; the additives are contained in the electrolyte The amount is 4%.

[0048] The preparation method of the carbon nanotube polymer lithium ion battery of the present embodiment, except that the coating surface density of step (2) slurry is 185g / ㎡, the coating density of step (3) ceramic material layer is 6g / mm 2 Except, other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com