Carbon nano fiber/ copper composite material and application thereof in thermal battery energy conversion device

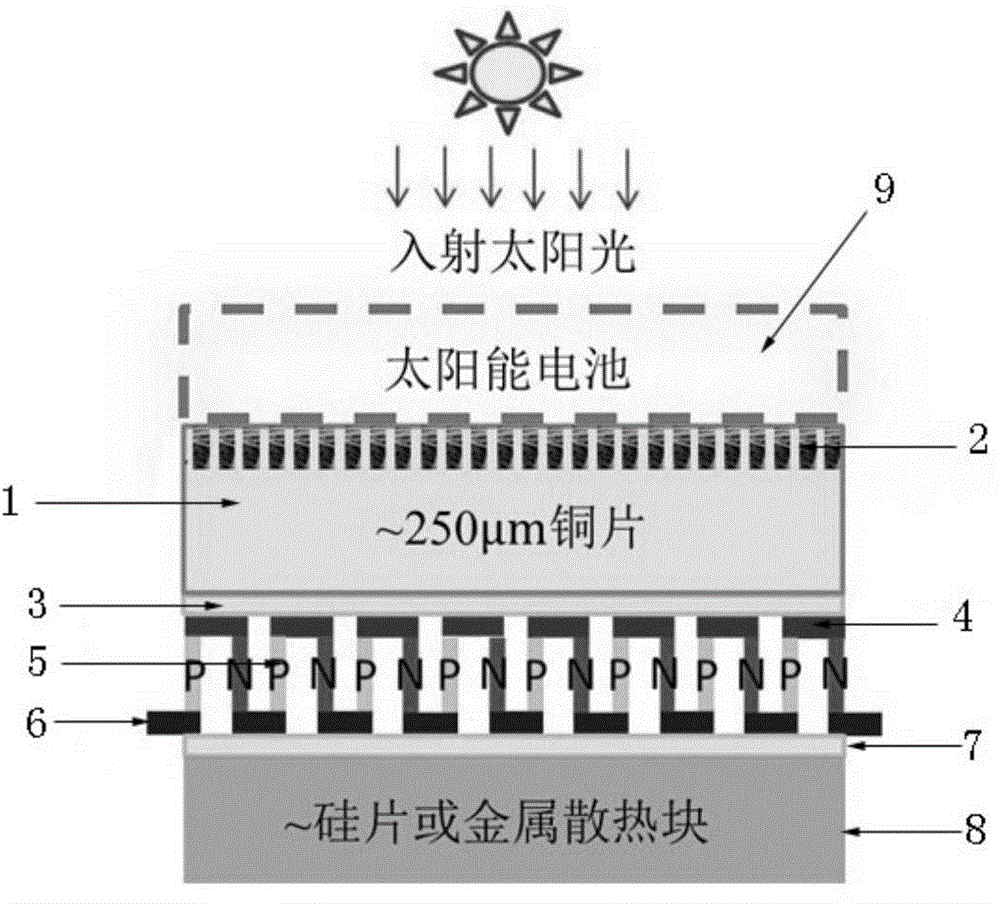

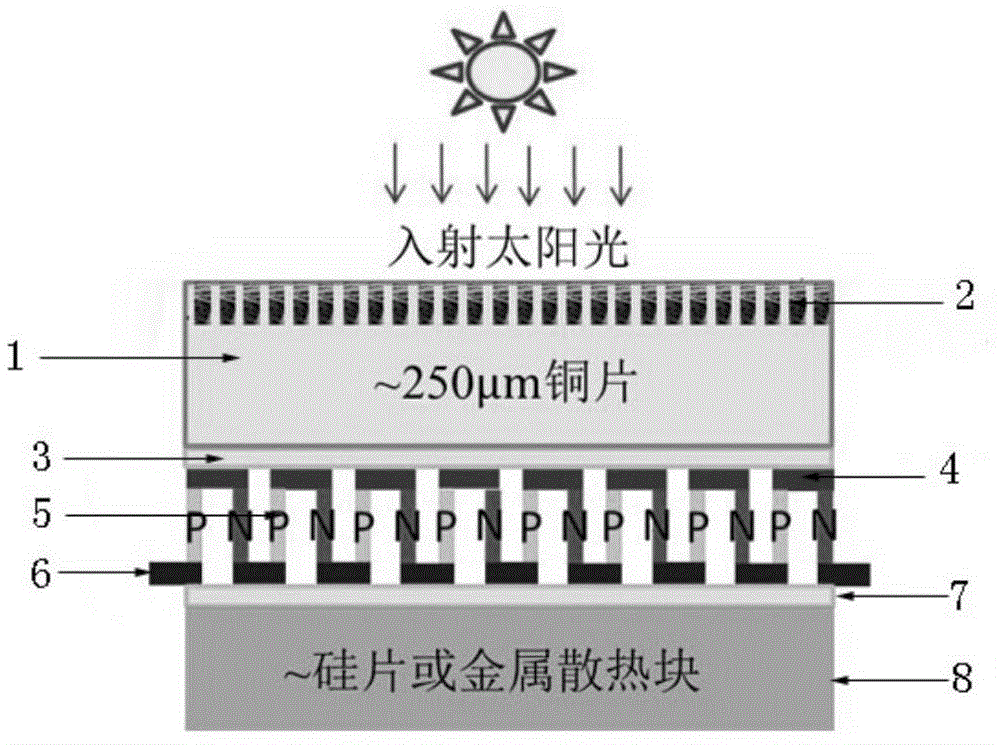

A carbon nanofiber, composite material technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve problems such as application limitations, complex equipment systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation process of the carbon nanofiber / copper composite material in this embodiment is as follows:

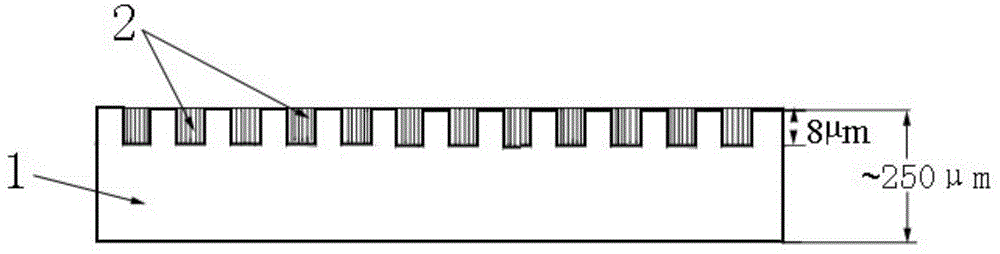

[0037] (1) Coating photoresist on one side surface of the copper base layer to form a pattern with a groove structure, and then in 1mol / L FeCl 3 Etching in the solution for 5 minutes to form a copper base layer with a groove structure on one side of the surface; the distance between the grooves is 20-30 μm, and the groove is about 8 μm.

[0038] (2) In an air atmosphere, heat the copper substrate with a groove structure to 485° C. for 20 minutes to roughen the part of the surface of the copper substrate layer that is not protected by photoresist, with a roughness of 3 to 7 μm;

[0039] (3) Remove the photoresist from the roughened copper base layer and place it in a CVD reaction chamber to grow nanowires. The growth conditions are: air pressure 500mbar, temperature 250°C, and growth time 15 minutes; The device is evacuated to 1 x 10 -2 mbar, the temperature wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com