Solid-state high-pressure mixing hydrogen storage tank

A technology of high-pressure mixing and hydrogen storage tanks, which is applied in the direction of fixed-capacity gas storage tanks, pressure vessels, gas/liquid distribution and storage, etc., can solve the problems of limited increase, application restrictions, and high energy consumption, and achieve easy manufacturing and processing, Improved continuous hydrogen supply capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

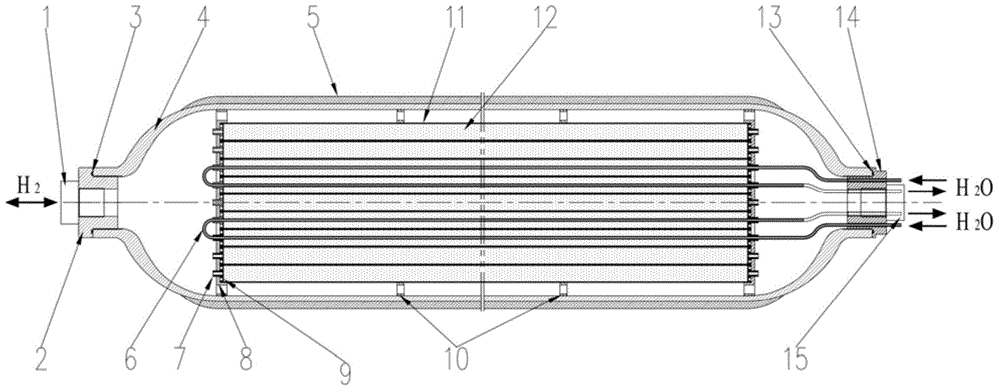

[0030] The present invention provides a solid-state high-pressure hybrid hydrogen storage tank. The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

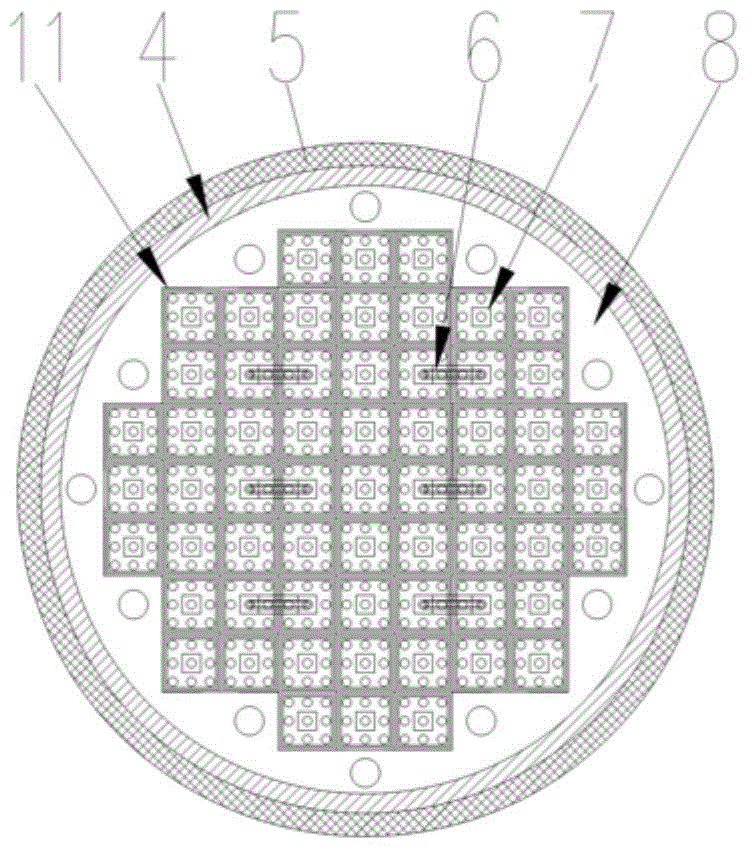

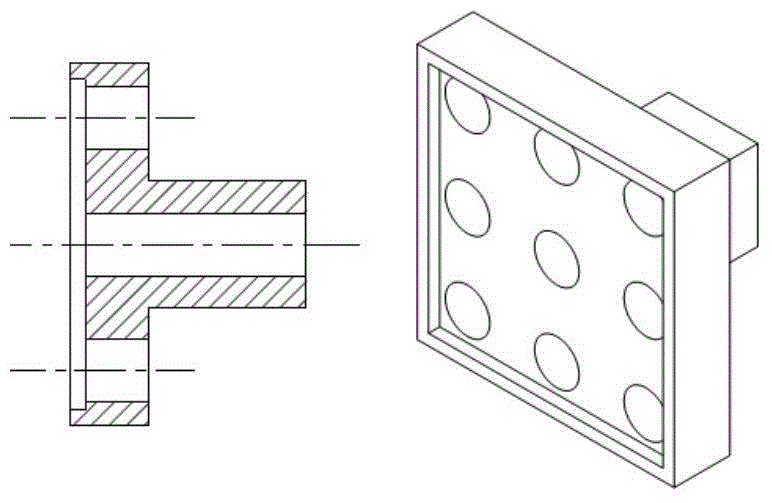

[0031] figure 1 A schematic cross-sectional view of the high-pressure solid-state hybrid hydrogen storage tank provided by the present invention, figure 2 Its cross-sectional schematic diagram. The main body of the solid-state high-pressure hybrid hydrogen storage tank is a metal liner 4, and the fiber winding reinforcement layer 5 is wound and laid on the outer surface of the metal liner 4. The material of the fiber winding reinforcement layer 5 is carbon fiber or glass fiber; A plurality of metal square tubes 11 that are in close contact and fixed by a plurality of support rings, the two ends of the metal square tube 11 are respectively welded to support and position plugs 7, and there are through holes in the support and position plugs 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com