Assembly type expanded-base grouting anchoring structure device and assembly construction method

An assembled and bottom-injected technology, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve problems such as the difficulty of guaranteeing the quality of bolt piles and bolt projects, the uncontrollable penetration and diffusion path and range, and the limitation of bearing capacity. , to achieve the effect of saving materials, reducing costs, and improving anti-corrosion durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

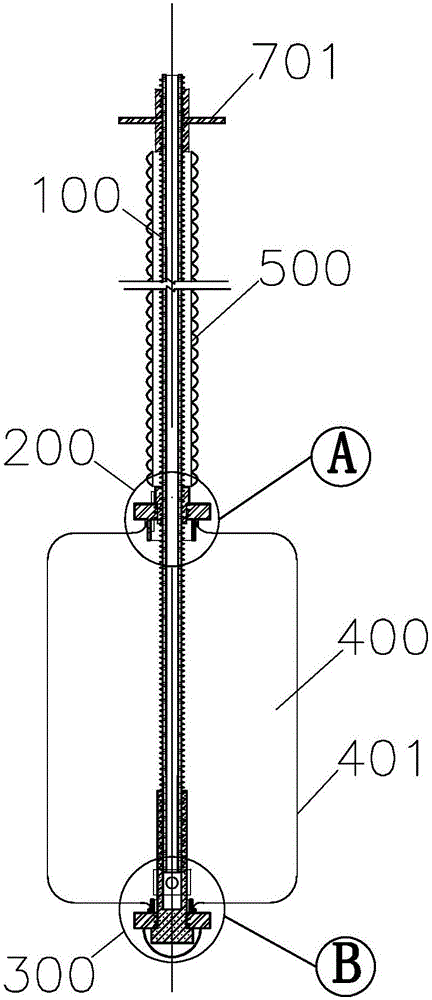

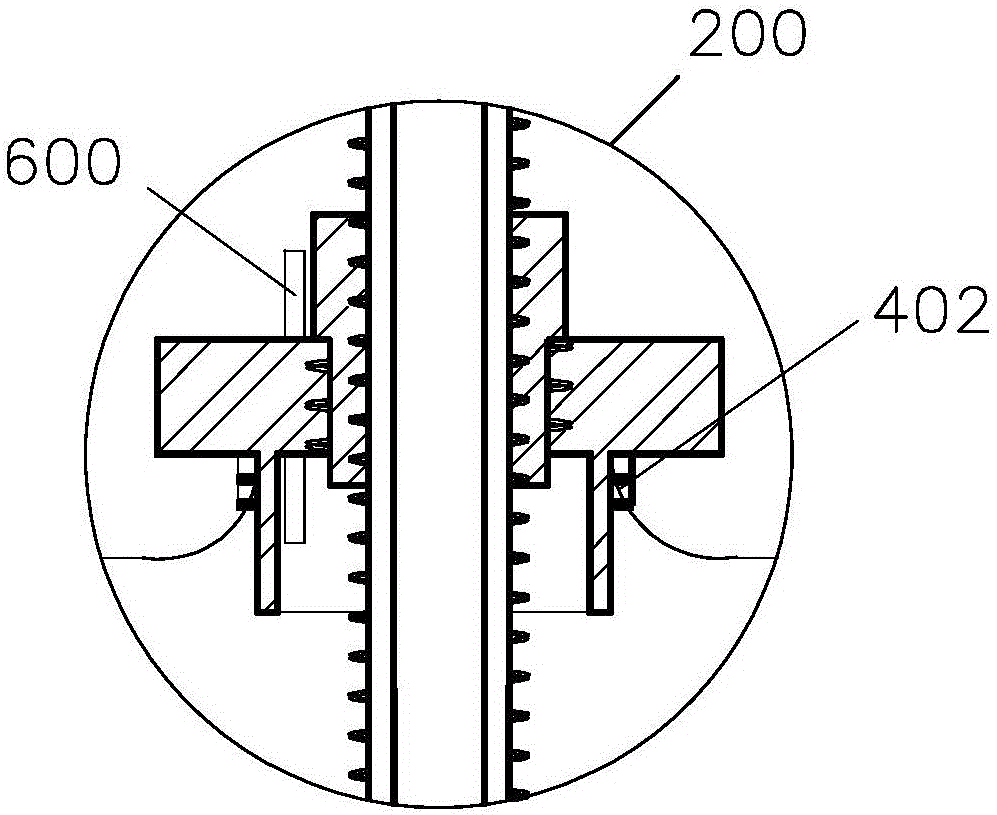

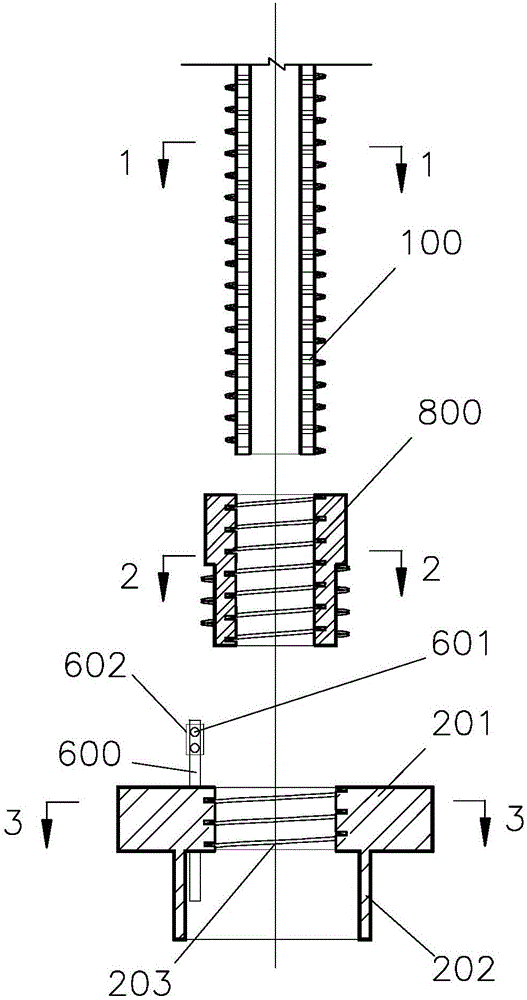

[0067] Such as Figure 1-10 As shown, Embodiment 1 of the present invention is an assembled bottom expansion grouting anchoring structure device, a CFRP, BFRP, AFRP, GFRP or high-strength steel hollow threaded pipe 100 with bearing and grouting functions, coaxially arranged from top to bottom There are the hollow threaded pipe 100, the upper sealing cylinder assembly 200, the bottom-expanded closed chamber 400 with a foldable and expanded bag cover 401, and the lower sealing bearing cylinder assembly 300, and a row through the upper sealing cylinder assembly 200 is provided. The air pipe 600 and the hollow threaded pipe 100 pass through the upper sealing cylinder assembly 200 one by one from top to bottom, the bottom-expanded closed chamber 400 and the lower sealing bearing cylinder assembly 300, and the hollow threaded pipe 100 carried are respectively It is sealingly connected and locked with the top cover plate 201 of the upper seal cylinder assembly 200 and the bearing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com