Wood-plastic composite and preparation method for special-shape molded member thereof

A technology of wood-plastic composite materials and pressed parts, which is applied in the field of wood-plastic composite material processing, can solve problems such as limiting the application range of wood-plastic composite materials, poor mechanical properties of wood-plastic composite materials, and inability to meet high-thickness requirements, and achieve a good market Application prospects, good application prospects, and the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

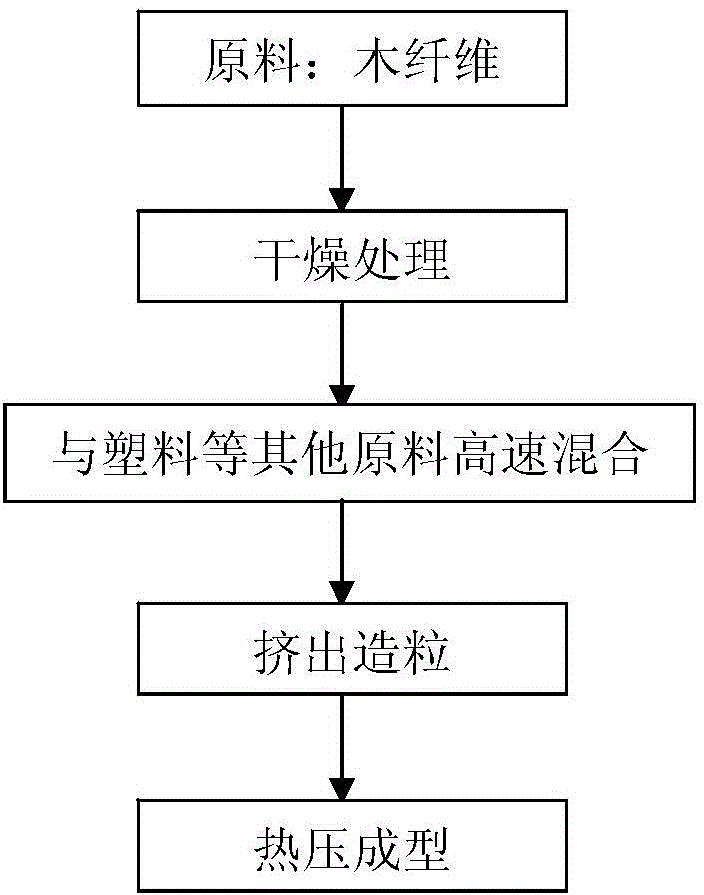

Method used

Image

Examples

Embodiment 1

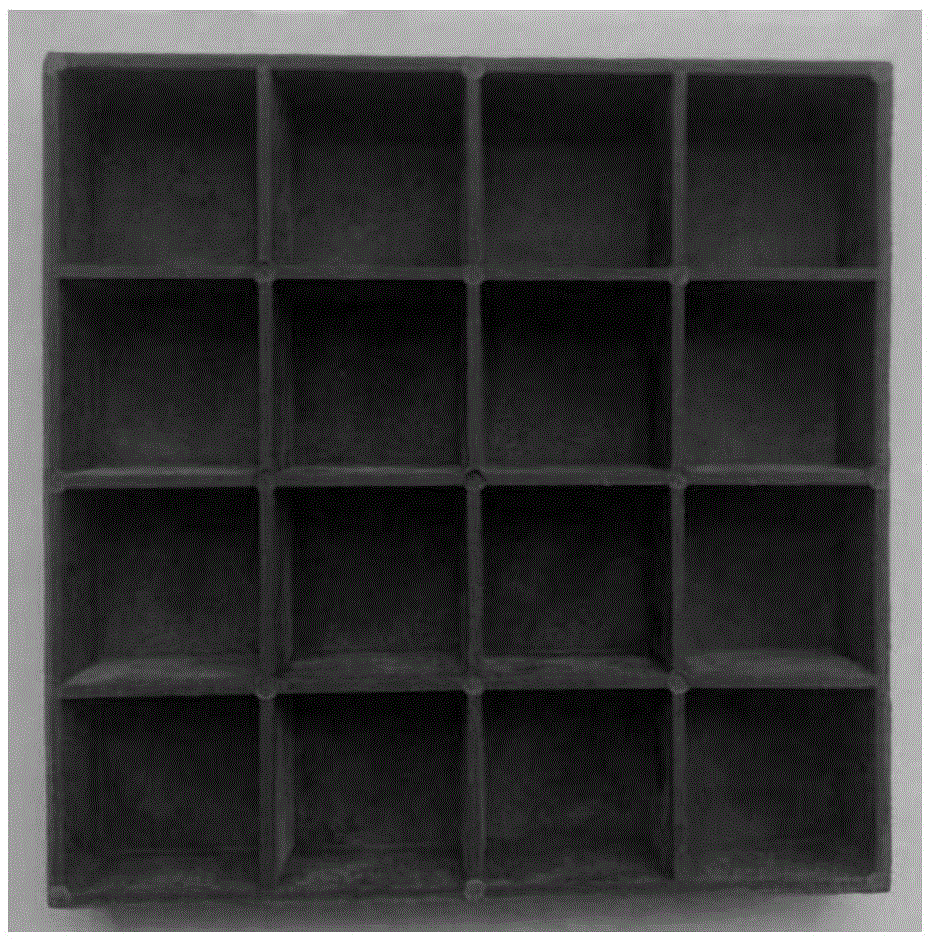

[0046] In this embodiment, the special-shaped molded wood-plastic product is a storage box with a format size of 500mm×500mm and a height of 100mm. The preparation method of the special-shaped molded wood-plastic product is as follows:

[0047] It is configured according to the following mass percentage raw materials:

[0048] The following are the specific production steps:

[0049] (1) Drying treatment

[0050] Select 820g of wood fiber with a length of 0.1-4.0mm and an aspect ratio of 10:1-100:1, and use a drum dryer to dry the wood fiber raw material, and control its moisture content at 5% to remove wood fiber. Moisture increases the interfacial compatibility between wood fiber and waste plastics;

[0051] (2) High speed mixing

[0052]Add the wood fiber, waste plastic polyethylene, coupling agent, lubricant, inorganic filler, color masterbatch and other functional additives after step (1) into the high-speed mixer according to the following mass percentage, and mix eve...

Embodiment 2

[0069] In this embodiment, the shape and format size of the special-shaped molded wood-plastic product are the same as those in Example 1. The preparation method of the special-shaped molded wood-plastic product is as follows:

[0070] (1) Drying treatment

[0071] Select 525g of wood fiber raw materials with a length of 0.1-4.0mm and an aspect ratio of 10:1-100:1, and use a blower dryer to dry the wood fiber, and control its moisture content at 4% to remove wood fiber. Moisture increases the interfacial compatibility between wood fiber and waste plastics;

[0072] (2) High speed mixing

[0073] Add the wood fiber, waste plastic polyethylene, coupling agent, lubricant, inorganic filler, color masterbatch and other functional additives after step (1) into the high-speed mixer according to the following mass percentage, and mix evenly to prepare the mixture. The temperature is controlled at 105°C and mixed at high speed for 15 minutes:

[0074] Wood fiber 61%

[0075] Waste...

Embodiment 3

[0090] In this embodiment, the shape and format size of the special-shaped molded wood-plastic product are the same as those in Example 1. The preparation method of the special-shaped molded wood-plastic product is as follows:

[0091] (1) Drying treatment

[0092] Choose 755g of special-shaped wood fiber raw materials with a length of 0.1-4.0mm and an aspect ratio of 10:1-100:1, and use a drum dryer to dry the wood fiber, and control its moisture content at 5% to remove wood fiber. Moisture increases the interfacial compatibility between wood fiber and waste plastics;

[0093] (2) High speed mixing

[0094] Add wood fibers treated in step (1), waste plastic polyethylene and polypropylene, coupling agent, lubricant, inorganic filler, color masterbatch and other functional additives into a high-speed mixer according to the following mass percentages, and mix evenly to obtain For the mixture, the temperature is controlled at 110°C and mixed at high speed for 10 minutes:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com