A method for separating nylon 66 and nylon 6 in polyamide heat insulation strips

A technology of heat insulation strip and polyamide, which is applied in recycling technology, plastic recycling, etc., can solve the problems of unprepared measurement results, inaccurate separation results, inaccurate separation, etc., and achieves low cost, low equipment requirements, Separation of high-accuracy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

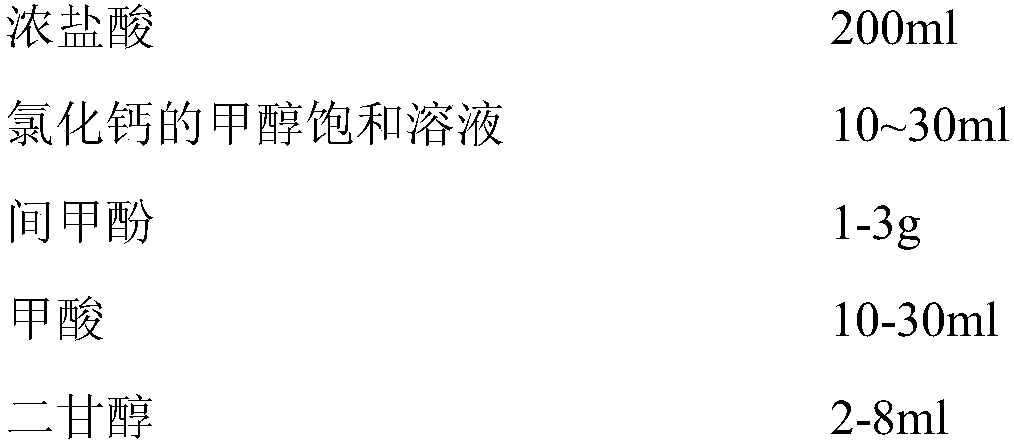

[0021] A. According to the following ratio

[0022]

[0023] Prepare a mixed solution, weigh 5g of polyamide insulation strip particles containing 54.95% nylon 66 and 13.74% nylon 6, and dissolve them in the mixed solution. Ultrasonic vibration and stirring are performed at 70°C under airtight conditions for 6 hours. The particle size of hot bar particles is less than 5mm;

[0024] B. Use a microporous cellulose filter membrane with a pore size of 0.45mm to perform the first suction filtration of the mixed solution dissolved with polyamide heat insulation strip particles to obtain a primary filtrate, slowly add water to the primary filtrate to dilute the precipitate, and gradually dilute the The primary filtrate of the precipitation is sampled and titrated, and when the concentration of hydrogen ions in the primary filtrate of the diluted precipitation is 5.05mol / l, stop adding water, and then the primary filtrate of the diluted precipitation that reaches the titration valu...

Embodiment 2

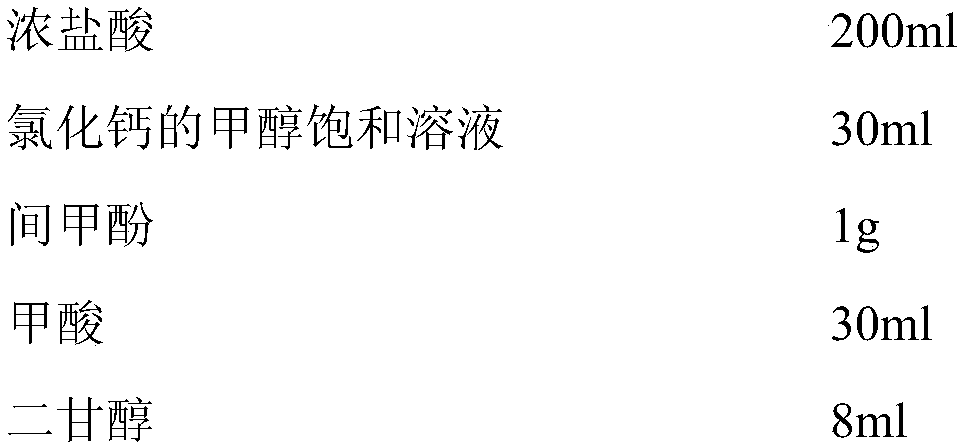

[0028] A. According to the following ratio

[0029]

[0030] Prepare a mixed solution, weigh 5g of polyamide insulation strip particles containing 48.08% nylon 66 and 20.6% nylon 6, and dissolve them in the mixed solution. Ultrasonic vibration and stirring are performed at 70°C under airtight conditions for 6 hours. The particle size of hot bar particles is less than 5mm;

[0031] B. Use a microporous cellulose filter membrane with a pore size of 0.45mm to perform the first suction filtration of the mixed solution dissolved with polyamide heat insulation strip particles to obtain a primary filtrate, slowly add water to the primary filtrate to dilute the precipitate, and gradually dilute the The primary filtrate of the precipitation is sampled and titrated, and when the concentration of hydrogen ions in the primary filtrate of the diluted precipitation is 5.20mol / l, stop adding water, and then the primary filtrate of the diluted precipitation that reaches the titration value...

Embodiment 3

[0035] A. According to the following ratio

[0036]

[0037] Prepare a mixed solution, weigh and dissolve the heat-insulating strip particles containing 41.21% nylon 66 and 27.47% nylon 6 in the mixed solution, ultrasonically vibrate and stir under airtight conditions at 70°C for 6 hours, and the polyamide heat-insulating strip particles The particle size is less than 5mm;

[0038] B. Use a microporous cellulose filter membrane with a pore size of 0.45mm to perform the first suction filtration of the mixed solution dissolved with polyamide heat insulation strip particles to obtain a primary filtrate, slowly add water to the primary filtrate to dilute the precipitate, and gradually dilute the The primary filtrate of the precipitation is sampled and titrated, and when the concentration of hydrogen ions in the primary filtrate of the diluted precipitation is 5.53mol / l, stop adding water, and then the primary filtrate of the diluted precipitation that reaches the titration valu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com