Automobile lower fender apron with automatic silt-discharging function

A sediment and functional technology, which is applied in the field of automobile underguards, can solve the problems of reducing production costs, shortening, etc., and achieve the effects of reducing production costs, solving cost costs, and improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

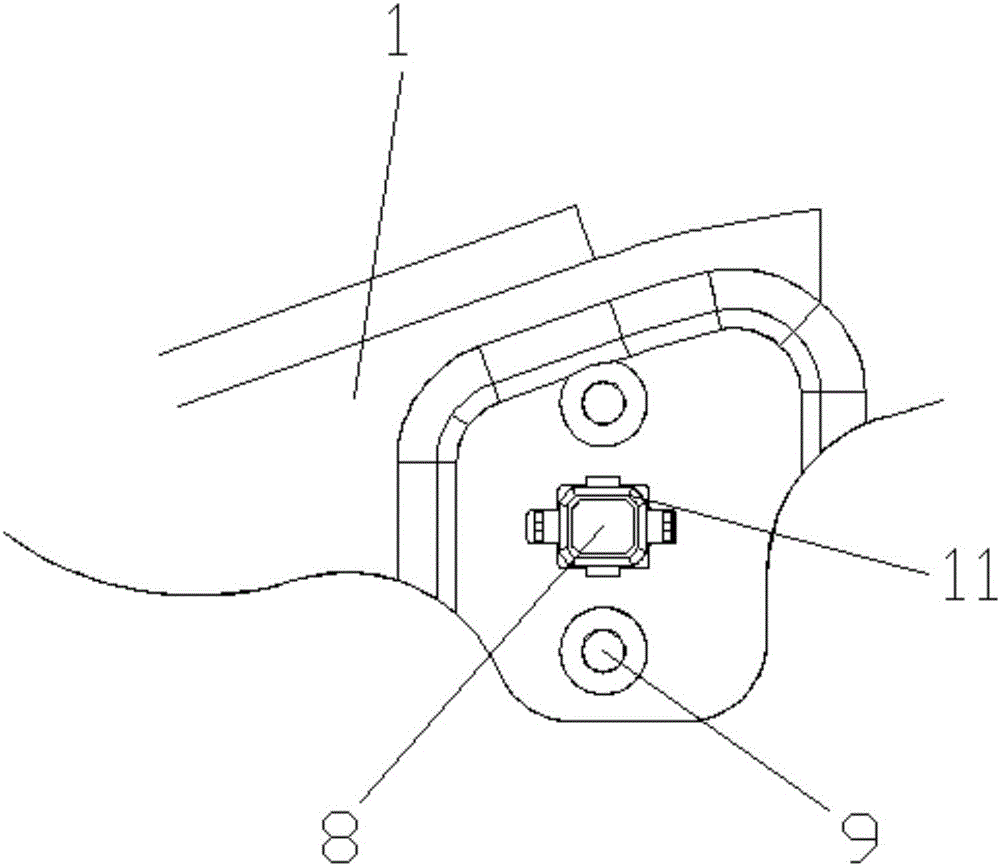

[0019] A kind of automobile lower guard plate with self-discharging silt function according to the present invention, such as Figure 1 ~ Figure 2 As shown, the plate body 1 is included, and the plate body 1 is provided with a plurality of water storage tanks 2, sediment discharge holes 3, and guard plate installation holes 6; the inside of the water storage tank 2 is provided with a water drop hole 4; a plate is formed between the water storage tanks 2 Body reinforcement rib 5; there are four sediment discharge holes 3, which are scattered in the lower part of the plate body 1 and located below the water tank 2, so as to avoid the reduction of the strength of the plate body caused by excessive concentration; the guard plate installation hole 6 is located in the plate body 1 is surrounded by a reinforcement and thickening mechanism 10 to ensure the structural strength of the guard plate installation hole 6 and avoid breakage; it is connected with the car body through bolts to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com