Low-cost and high-efficiency machining method for cycloid gears

The technology of a cycloid gear and a processing method, which is applied in the field of gear processing, can solve the problems of low efficiency, increase the manufacturing cost of the reducer, and high processing cost, achieve the effects of high finish, solve the complex production process, and reduce the processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

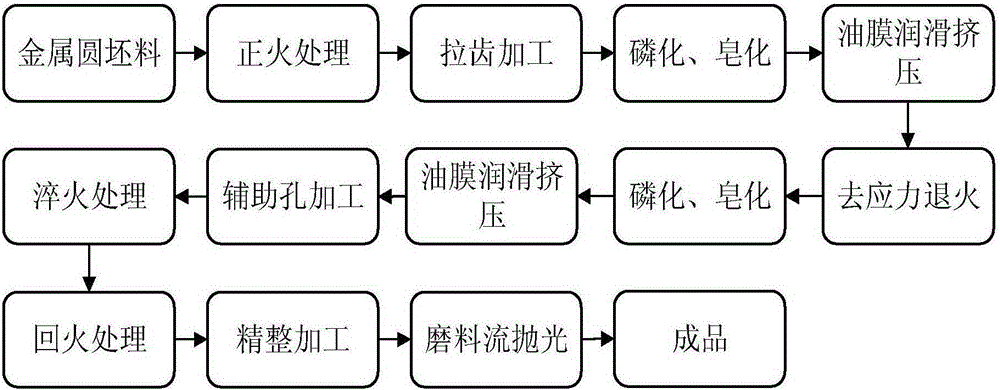

[0031] A low-cost and high-efficiency machining method for a cycloidal gear, comprising the following process steps:

[0032] (1) Select No. 45 steel round billet with better comprehensive mechanical properties as the raw material;

[0033] (2) Normalizing: heat to 920°C, hold for 1 hour, quickly cool to 600°C, hold for 1 hour, take it out of the furnace and cool in the air;

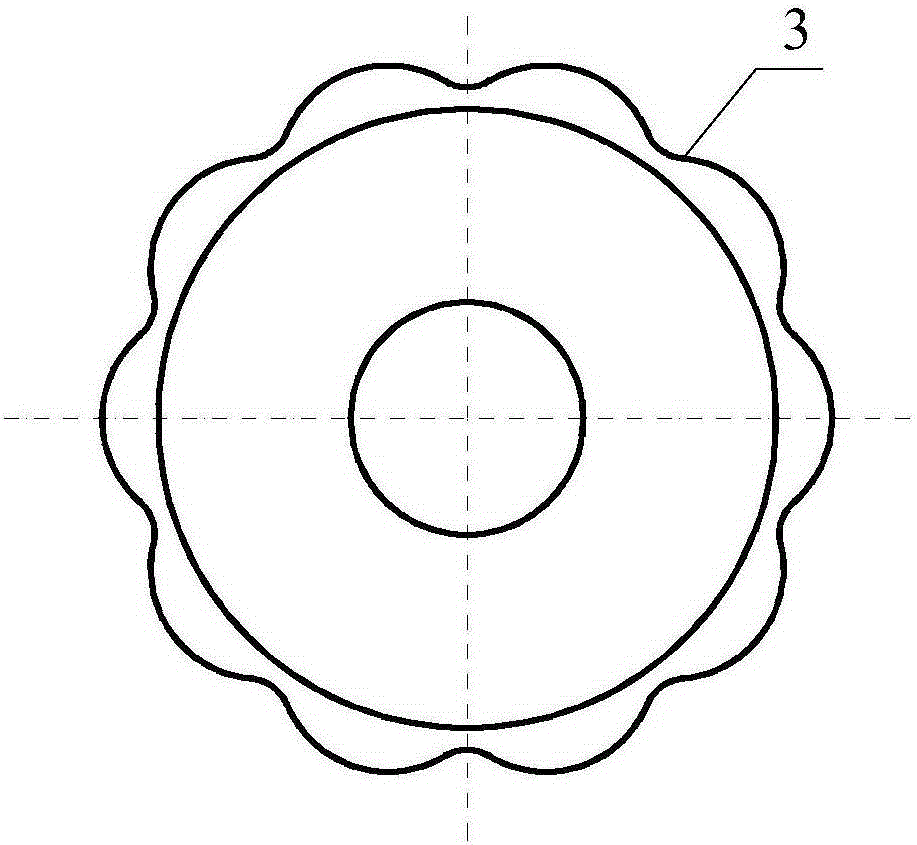

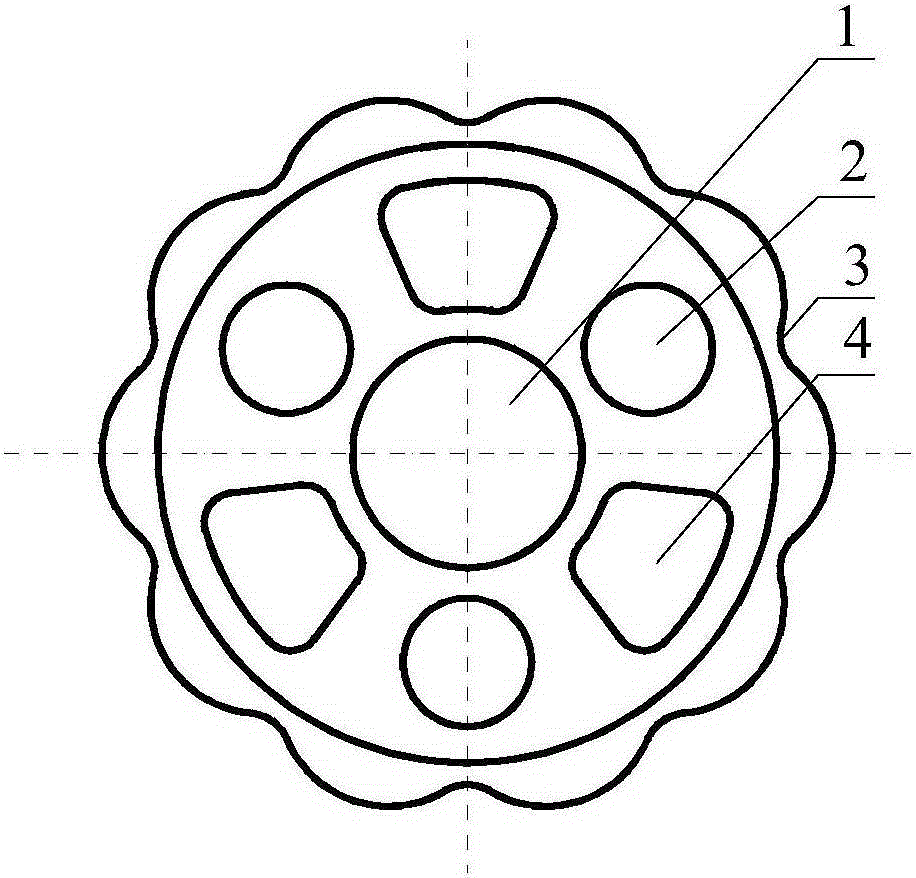

[0034] (3) Carry out bearing hole 1 processing on the round billet after normalizing treatment, and then carry out broaching processing on the billet with the bearing hole 1 positioned to obtain a cycloidal 3-tooth shape (such as figure 2 shown);

[0035] (4) Phosphate and saponify the billet after broaching in the phosphating solution and saponification solution. The components of the phosphating solution are: zinc dihydrogen phosphate 60 g / l and zinc nitrate 110 g / l, The temperature of the solution is 70°C. Wash the pickled workpiece with water and put it into the prepared phosphating solution for p...

Embodiment 2

[0045] A low-cost and high-efficiency machining method for a cycloidal gear, comprising the following process steps:

[0046] (1) Select the 20CrMnTi alloy steel round billet with high strength and toughness as the raw material;

[0047] (2) Normalizing: heat to 930°C, keep warm for 2 hours, quickly cool to 600°C and keep warm for 3 hours, take it out of the furnace and cool in air;

[0048] (3) Carry out bearing hole 1 processing on the round billet after normalizing treatment, and then carry out broaching processing on the billet with the bearing hole 1 positioned to obtain a cycloidal 3-tooth shape (such as figure 2 shown);

[0049] (4) Phosphate and saponify the billet after broaching in the phosphating solution and saponification solution. The components of the phosphating solution are: zinc dihydrogen phosphate 60 g / l and zinc nitrate 110 g / l, The temperature of the solution is 80°C. Wash the pickled workpiece with water and put it into the prepared phosphating soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com