Method for extracting tyrosinase inhibitor from common camellia bee pollen

A technology of tyrosinase and Camellia bee, which is applied in the field of preparation of tyrosinase inhibitors, can solve the problems of low added value, low price, and insufficient development and utilization of bee pollen resources, so as to reduce damage and shorten the cycle , Improve the effect of added value and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

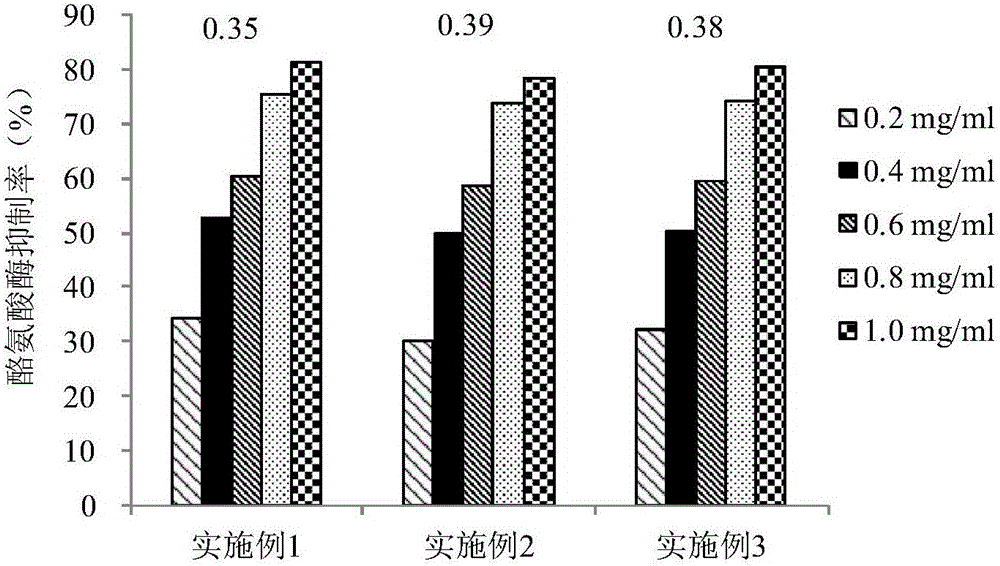

Embodiment 1

[0021] (1) Grinding the dried camellia bee pollen, adding 10 times the weight of petroleum ether, ultrasonication for 1 hour, degreasing 3 times, suction filtration to obtain the filter residue, drying the filter residue, and removing the residual petroleum ether;

[0022] (2) Add 80% ethanol aqueous solution as extractant to the degreased camellia bee pollen, the ratio of solid to liquid is 1g:30ml, ultrasonic extraction is carried out under the condition of 50°C, the extraction time is 35min, the ultrasonic power is 100W, and the extraction times are 3 times, after extraction, suction filtration, rotary evaporation and concentration of the extract, and vacuum freeze-drying to obtain the alcoholic extract of camellia bee pollen;

[0023] (3) Add distilled water to the alcohol extract of camellia bee pollen by the ratio of 1g:10ml with the alcohol extract of camellia bee pollen and distilled water obtained above, and ultrasonically disperse the alcohol extract of camellia bee p...

Embodiment 2

[0026] (1) Grinding the dried camellia bee pollen, adding 5 times the weight of petroleum ether, ultrasonication for 2 hours, degreasing 3 times, suction filtration to obtain the filter residue, drying the filter residue, and removing the residual petroleum ether;

[0027] (2) Add 70% ethanol aqueous solution to the degreased camellia bee pollen as an extractant, the ratio of solid to liquid is 1g:40ml, ultrasonic extraction is carried out at 40°C, the extraction time is 40min, the ultrasonic power is 200W, and the extraction times are 3 times, after extraction, suction filtration, rotary evaporation and concentration of the extract, and vacuum freeze-drying to obtain the alcoholic extract of camellia bee pollen;

[0028] (3) With the alcohol extract of camellia bee pollen and distilled water obtained above as a ratio of 1g: 6ml, add distilled water to the alcohol extract of camellia bee pollen, ultrasonically disperse the alcohol extract of camellia bee pollen into distilled w...

Embodiment 3

[0031] (1) Grinding the dried camellia bee pollen, adding 20 times the weight of petroleum ether, ultrasonic degreasing once, suction filtration to obtain the filter residue, drying the filter residue, and removing the residual petroleum ether;

[0032] (2) Add 90% ethanol aqueous solution to the degreased camellia bee pollen as an extractant, the ratio of solid to liquid is 1g: 20ml, carry out ultrasonic extraction at 45°C, the extraction time is 30min, the ultrasonic power is 100W, and the extraction times are 2 After extraction, suction filtration is performed, the extract is concentrated by rotary evaporation, and vacuum freeze-dried to obtain the alcoholic extract of camellia bee pollen;

[0033] (3) With the alcohol extract of Camellia bee pollen and distilled water obtained above as a ratio of 1g: 8ml, add distilled water to the alcohol extract of Camellia bee pollen, dissolve it by ultrasonic and centrifuge, and separate the filtrate;

[0034] (4) Adsorb the AmberliteX...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com