Preparation method of three-dimensional graphene lactic acid sensor

A sensor, the technology of lactic acid, applied in the field of biochemical sensors, can solve the problems of electrical conductivity, limited biocompatibility, low electron transmission speed, and weak tensile properties of materials, so as to improve sensitivity and cost The effect of low cost and superior electron transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the accompanying drawings and examples.

[0027] Implementation column 1

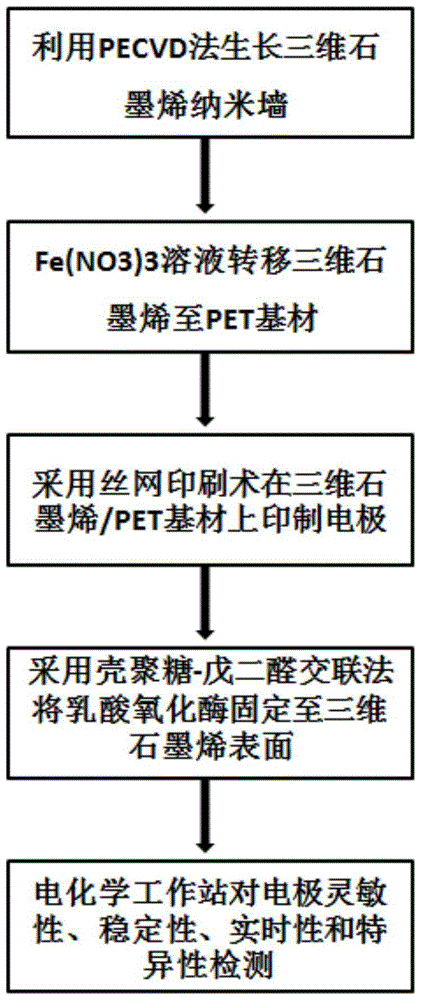

[0028] This embodiment provides a method for preparing a three-dimensional graphene lactic acid sensor, the process flow chart of the method is as follows figure 1 As shown, the specific steps are as follows:

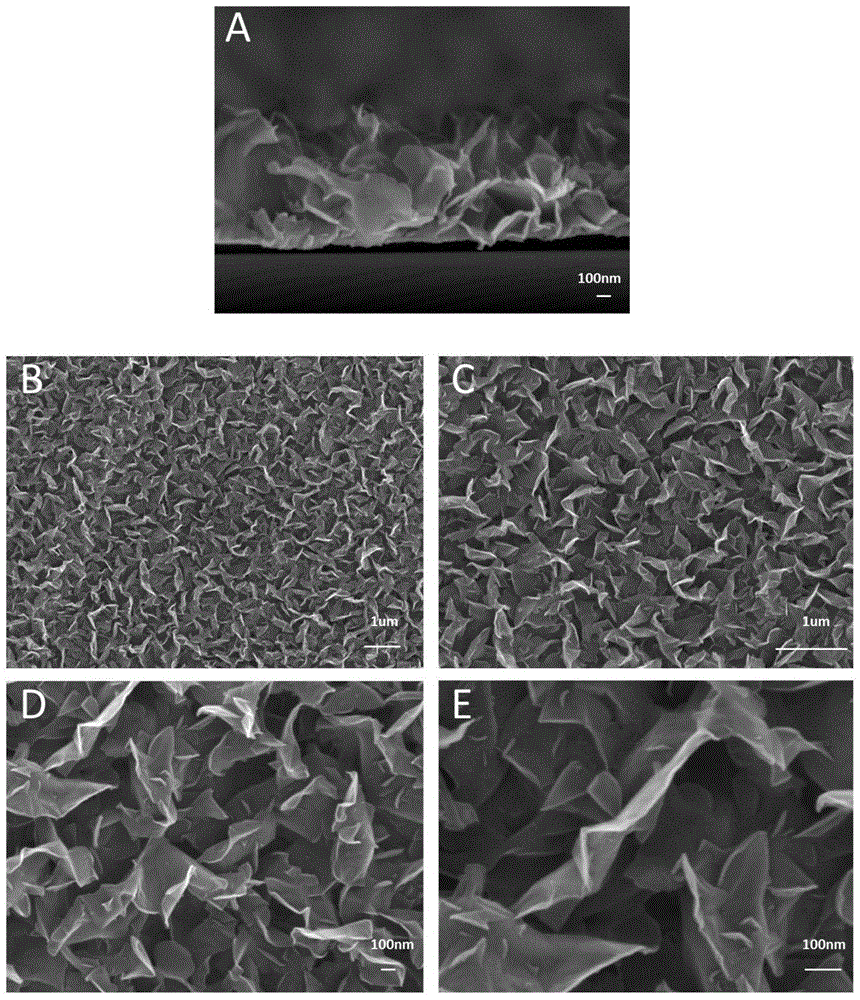

[0029] 1. Using the PECVD method, place a 20 μm thick copper foil horizontally in the glass tube of the growth furnace, and go through three steps of heating, annealing, and growth. The conditions are: heating: 30min to 500°C, hydrogen = 5, 10, 15, 20, 25, 30sccm; annealing: 30min, maintaining 600°C, hydrogen = 5sccm; growth: 60min, maintaining 600°C, methane: hydrogen = 4:8sccm, radio frequency = 200mw; turn off radio frequency and methane after the growth is over, set the hydrogen to 2sccm, turn on the fan to cool down quickly, and finally gently take out the copper foil with the graphene wall grown on it, the prepared t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com