Precision scale or mass comparator with module for detecting a measurement uncertainty

A technology for measuring uncertainty and determining modules. It is applied to weighing equipment with special properties/forms of materials, containers for laboratory use, and determining specific gravity by measuring pressure difference. It can solve the problem of external parameters affecting weighing. Results and other issues to achieve the effect of eliminating transmission errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

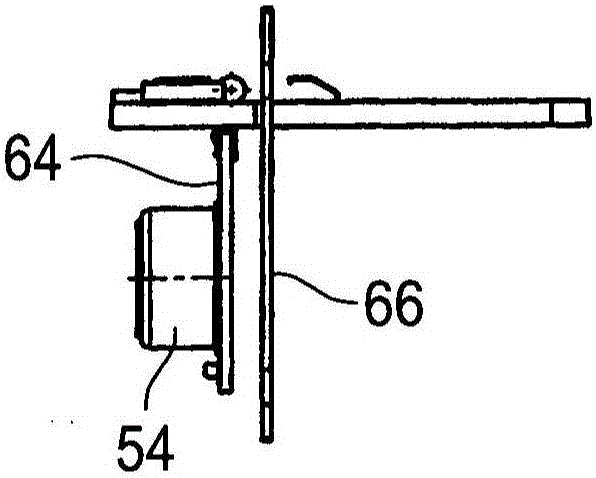

[0031] exist figure 1 A high-resolution electronic precision balance is shown in , which in this example is capable of mass comparisons in all precision classes according to OIMLR111-1 and according to ASTME617-13.

[0032] The precision weighing device comprises a weighing cell 14 with a base 12 into which a weighing system 10 , not shown in detail, is mounted. Furthermore, the weighing cell 14 includes a weighing chamber 16 , which is formed by a draft shield with adjustable side walls 18 , a front wall 20 and a rear wall 22 . The weighing chamber 16 can be separated from the surroundings by means of a draft shield. The weighing pan 24 is used to support weighing objects.

[0033] Electronic evaluation system 26 embodied here as a separate component is electrically coupled via cable 28 to weighing cell 14 . A display unit 30 coupled to the evaluation system 26 serves both as a display and as a data input unit.

[0034] In particular, a processor 32 is installed in electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com