High-power automobile starter and stator magnetic steel fixing method

A starter, high-power technology, applied in the field of vehicle engineering, can solve the problems of complex production process of electric excitation starter, unfavorable workers' health and environmental protection, high production cost, and achieve high cost performance, reduced scrap rate, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

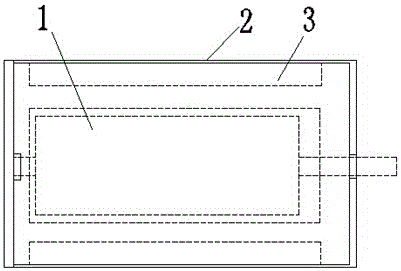

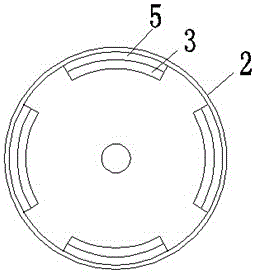

[0037] refer to figure 1 with figure 2 , the present embodiment provides a high-power automobile starter, comprising a rotor 1 and a stator housing 2, the inner wall of the stator housing 2 is distributed along its circumferential direction with permanent magnet magnets 3, and the permanent magnet magnets 3 are all It is Ru-Fe-B magnet, and the permanent magnet magnets 3 are evenly distributed along the circumferential direction of the inner ring of the stator housing 2, and each stator housing 2 is provided with 4 permanent magnet magnets 3, that is, four-stage magnetic cylinders, The permanent magnet magnetic steel 3 is fixed on the inner wall of the stator housing 2 through soft iron 5, and the magnetic poles of the motor are installed according to the circumferential order of N-S-N-S according to the polarity.

Embodiment 2

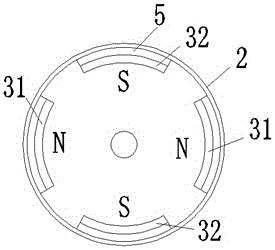

[0039] refer to figure 1 with image 3 , the present embodiment provides a high-power automobile starter, comprising a rotor 1 and a stator housing 2, the inner wall of the stator housing 2 is distributed along its circumferential direction with permanent magnet magnets 3, and the permanent magnet magnets 3 are all It is a hybrid magnet for both RuFeB magnets and ferrite magnets. The permanent magnet magnets 3 are evenly distributed along the circumferential direction of the inner ring of the stator housing 2. Among any two adjacent permanent magnet magnets 3, one of them is It is ferrite magnet, and the other is RuFeB magnet. There are four permanent magnet magnets 3 inside the stator housing 2, that is, four-stage magnet cylinders. The permanent magnet magnets 3 are fixed to the stator housing through soft iron 5. On the inner wall of the body 2, the magnetic poles of the motor are arranged in the circumferential order of N-S-N-S according to the polarity.

Embodiment 3

[0041] refer to figure 1 with Figure 4 , the present embodiment provides a high-power automobile starter, comprising a rotor 1 and a stator housing 2, the inner wall of the stator housing 2 is distributed along its circumferential direction with permanent magnet magnets 3, and the permanent magnet magnets 3 are Ferrite magnets, or hybrid magnets used both as RuFeB magnets and ferrite magnets, permanent magnet magnets 3 are evenly distributed along the circumferential direction of the inner ring of the stator housing 2, and each stator housing 2 There are four permanent magnet magnets 3 inside, that is, four-stage magnet cylinders. The permanent magnet magnets 3 are fixed on the inner wall of the stator housing 2 through the lateral fixing parts 6. Since the thickness of the permanent magnet magnets 3 is reduced, The stator housing can be downsized while adapting to existing rotors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com