Preparation method of triazole-based ionic crystal / polymer composite film

An ionic crystal and triazole-based technology, which is applied in the field of preparation of triazole-based ionic crystal/polymer composite membranes, can solve the problems of unstable electrochemical performance, easy loss, and reduced conductivity of the membrane, and is suitable for Large-scale production, not easy to lose, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of 1H-1,2,4-triazole methylsulfonate ([Tri][MS]): Measure 50ml of acetone into a three-necked flask, weigh 3.0011g of 1H-1,2,4-triazol Azole, dissolved in acetone, stirred to dissolve. Add 6.2896g methanesulfonic acid (mol ratio: triazole: methanesulfonic acid = 1:1.5) dropwise. With the addition of methanesulfonic acid, white crystals are formed in the solution and react for 2 hours. Filter and finally wash with ethyl acetate suction. Dry at 60°C for later use.

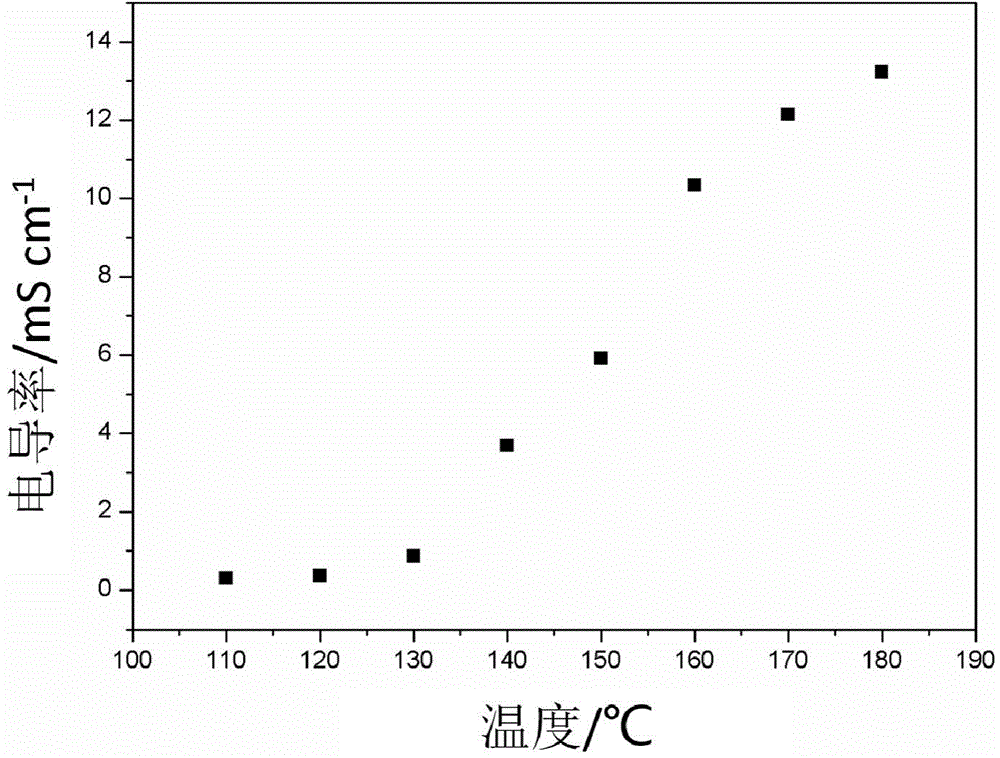

[0030] Preparation of 1H-1,2,4-triazole methylsulfonate ([Tri][MS]) / Nafion composite membrane: Weigh 2.0300g methanol, add 0.7202g1H-1 to a 60*30cm volumetric flask ,2,4-Triazole methanesulfonate ([Tri][MS]), prepared as [Tri][MS] / methanol solution. Soak 4*4cm Nafion212 membrane into [Tri][MS] / methanol solution, the size after swelling: 4.7*4.9cm. Soak in a vacuum oven for 24 hours at room temperature. Take it out and dry it at room temperature. Melt 10.0025g [Tri][MS] at 150°C, dip the membr...

Embodiment 2

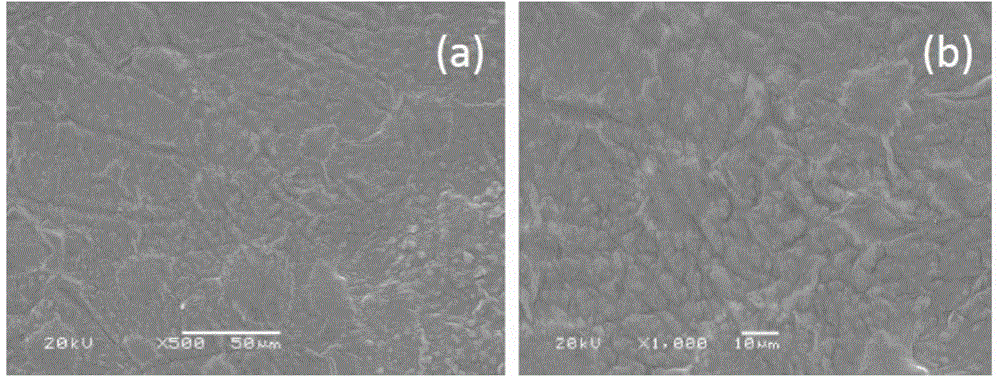

[0033] Preparation of 1H-1,2,4-triazole methylsulfonate ([Tri][MS]) / non-woven fabric composite membrane: Weigh 2.5305g methanol, add 0.9352g1H to a 60*30cm volumetric flask -1,2,4-Triazole methanesulfonate ([Tri][MS]), formulated as [Tri][MS] / methanol solution. Soak a 4*4cm non-woven fabric into the [Tri][MS] / methanol solution. Soak in a vacuum oven for 24 hours at room temperature. Take it out and dry it at room temperature. The membrane was immersed in molten [Tri][MS] at 150 °C. After sealing and immersing for 24 hours, take it out and wipe off the surface [Tri][MS] at 150°C with filter paper. The thickness of [Tri][MS] / non-woven composite film is 45 μm. [Tri][MS] loading was 75wt.%.

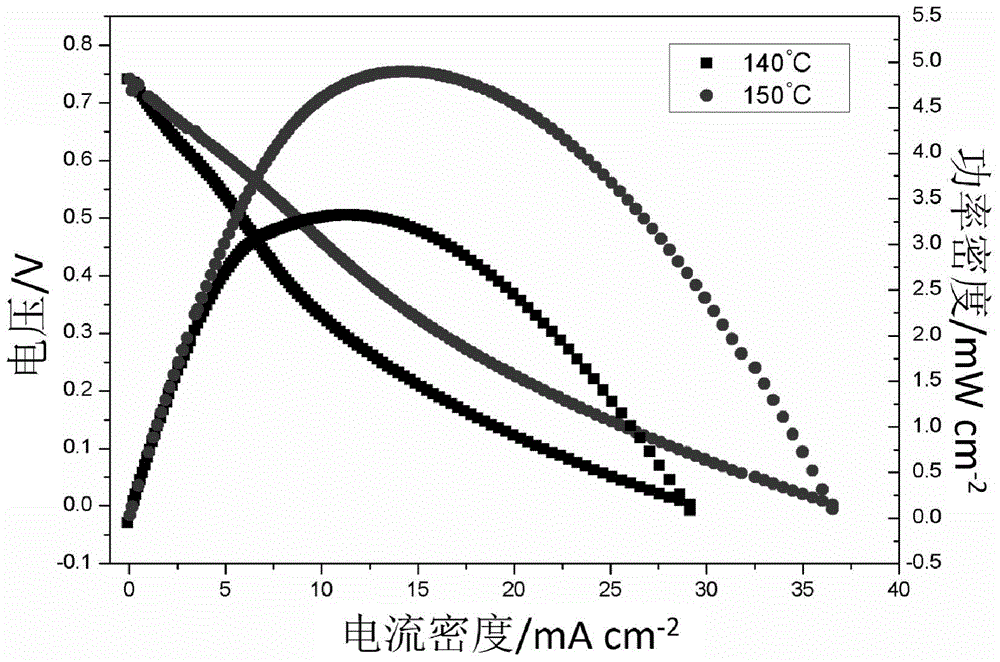

[0034] The cross-sectional view of the composite membrane of the membrane is shown in the appendix Figure 4 , the resulting MEA was assembled into a high-temperature fuel cell, and the battery performance was tested on a single-cell evaluation device. The catalyst Pt loading in the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com