Method for preparing explosive sensor array based on manganese-doped zinc sulfide nano-crystal

A manganese-doped zinc sulfide and sensor array technology is applied in the field of explosive detection, which can solve the problems of difficulty in realizing the atmosphere detection and low vapor pressure of non-standard explosive-making raw materials, and achieve the effect of making up for easy interference and rapid identification and detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare the sensor:

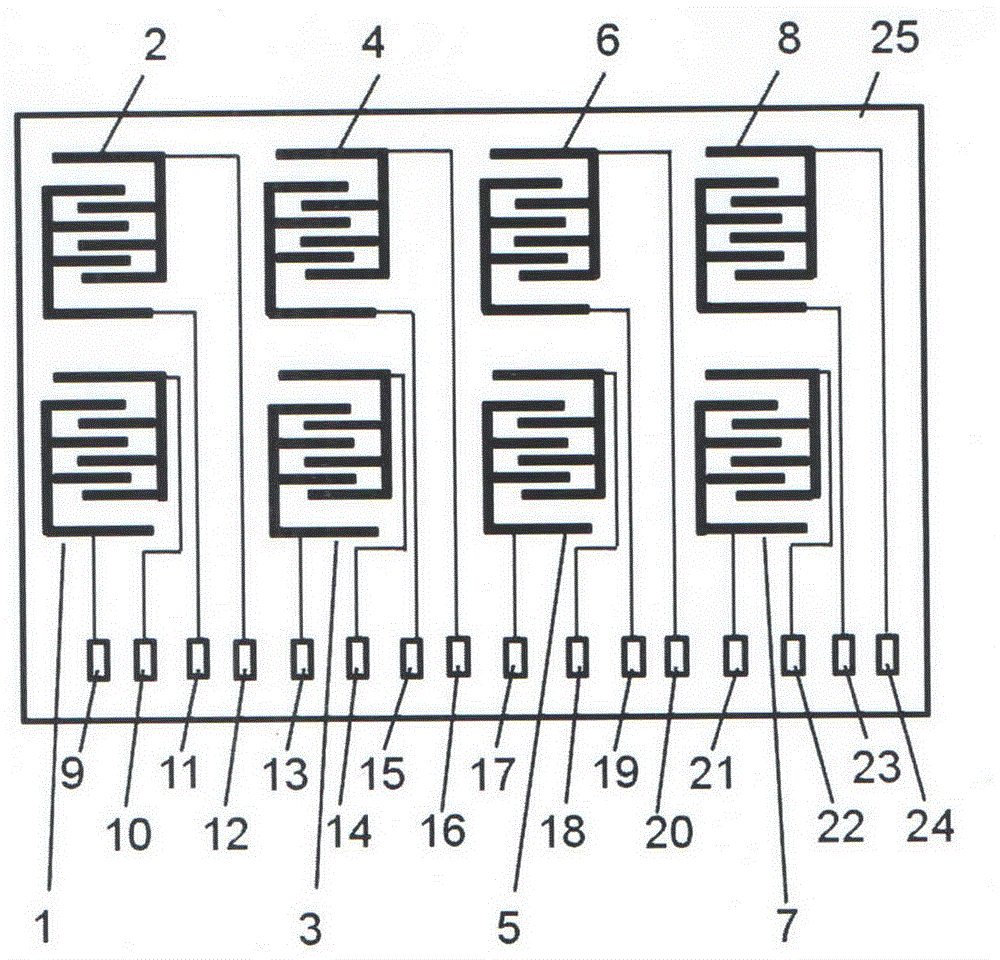

[0034] The second sensor 2, the fourth sensor 4, the sixth sensor 6 and the eighth sensor 8 and the first sensor 1, the third sensor 3, the fifth sensor 5 and the seventh sensor 7 are respectively fixed up and down on the ceramic substrate 25. The sensor 1 is respectively connected to the first electrode 9 and the second electrode 10 through the connecting wires at the upper end and the lower end, and the second sensor 2 is respectively connected to the third electrode 11 and the fourth electrode 12 through the connecting wires at the upper end and the lower end. The third sensor 3 Connect the fifth electrode 13 and the sixth electrode 14 through the connection wires at the upper end and the lower end respectively, the fourth sensor 4 is respectively connected with the seventh electrode 15 and the eighth electrode 16 through the connection wires at the upper end and the lower end, and the fifth sensor 5 The connecting wires at the lower end are res...

Embodiment 2

[0044] Prepare the sensor according to Example 1;

[0045] Preparation of gas-sensitive materials:

[0046] a. Dissolve zinc acetate and manganese acetate in 40-50mL of deionized water at a molar ratio of 100:0-20, and ultrasonically obtain a zinc-manganese mixture solution for 20 minutes. The concentration of zinc ions is 1-1.5mol / L;

[0047] b. After feeding the mixture obtained in step a into nitrogen for 30 minutes, get sodium sulfide with an equimolar amount of zinc acetate and dissolve it in 10 mL of deionized water, ultrasonically for 5 minutes, and keep the concentration of sodium sulfide at 4-6mol / L. Add the sodium sulfide solution dropwise to the mixture obtained in step a, and continue to stir and react at a temperature of 0-30°C for 3-8 hours to obtain manganese ion doping concentrations of 0%, 1%, 1.6%, and 2%, respectively. , 5%, 10%, 14% and 20% zinc sulfide nanocrystal precipitation;

[0048] c. The precipitate obtained in step b is ultrasonically washed with...

Embodiment 3

[0054] Explosives sensor array detection of explosives and their raw materials:

[0055] Connect the Catherine ammeter power supply, under the bias voltage of 4V, test the sensor array that embodiment 1-2 obtains arbitrarily, under room temperature (temperature 25 ℃, relative humidity 25%) in air and 2,4-dinitrotoluene Resistance in saturated vapor, it can be seen from the response curve that at room temperature, the response of the zinc sulfide-based resistive sensor array to the explosive 2,4-dinitrotoluene reaches 18.3%, 19.9%, 33.7%, 37.5% respectively. %, 45.4%, 38.5%, 28.5%, and 27.8%; response times were 4, 4, 3, 3, 3, 4, 4, and 5 seconds; recovery times were 7, 6, 5, 9, 5, 7 , 7 and 8 seconds (eg Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com