Method and apparatus for preparing gas sensor

A gas sensor and gas technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex manufacturing process, high equipment price, and limited application, and achieve the goal of avoiding complex process, extensive engineering application value, and making up for response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

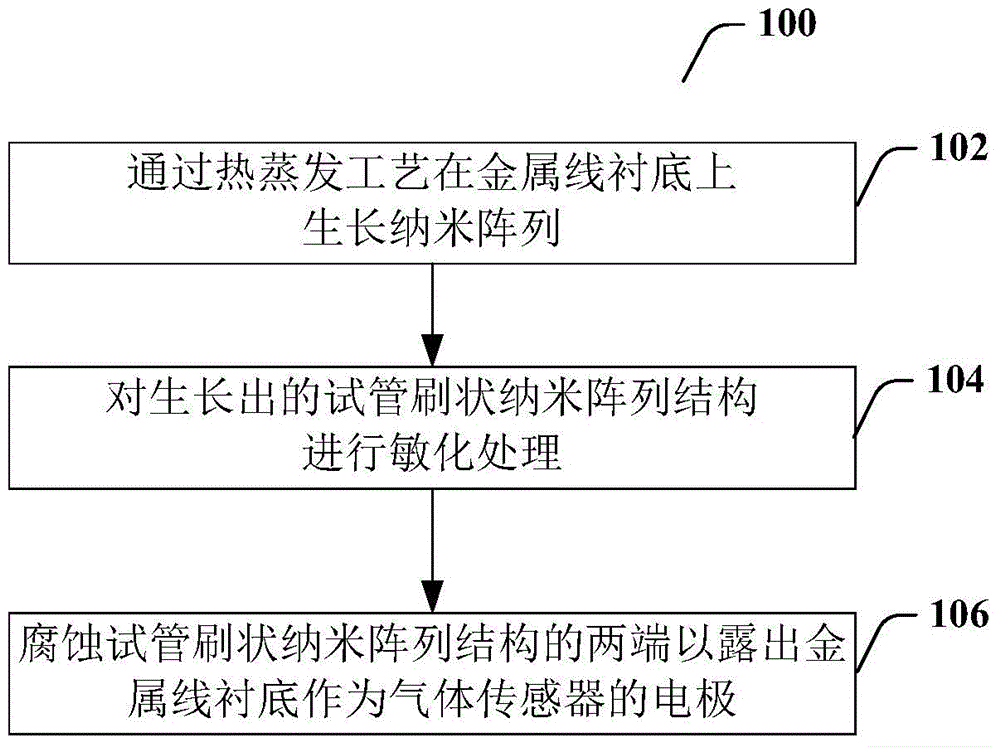

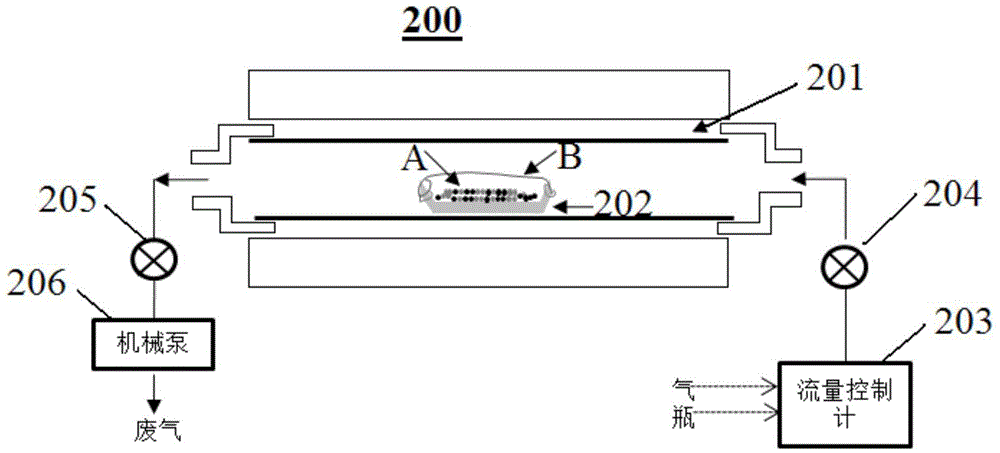

[0046] In view of the fact that traditional one-dimensional nanostructured gas sensors are complicated to manufacture, the cost is high, and the performance of gas sensors with two-dimensional thin film structures is low, the present invention provides a simple, economical and controllable method based on nanoarrays (for example, ZnO nanoarrays) to prepare Gas sensor method. The method cleverly combines the macrostructure (gold wire) with the microstructure (ZnO nanoarray), and through a controllable structure design process, a nanoarray structure with a high specific surface area is obtained to improve the adsorption capacity of the nanostruc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com