Coal-fired power plant energy level matching heat integration system based on primary air

An energy-level matching, coal-fired power station technology, applied in preheating, combustion methods, feedwater heaters, etc., can solve the problems of limited energy saving potential, difference in steam extraction efficiency, less than 10%, etc., and achieve limited investment demand and output. Flexible, System-Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments will be described in detail below in conjunction with the accompanying drawings.

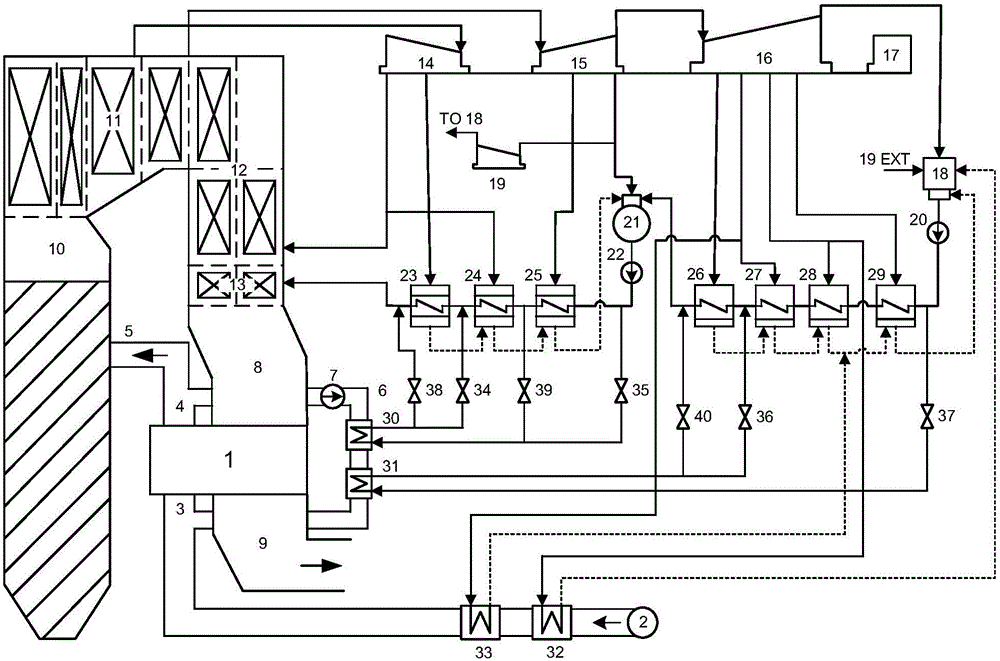

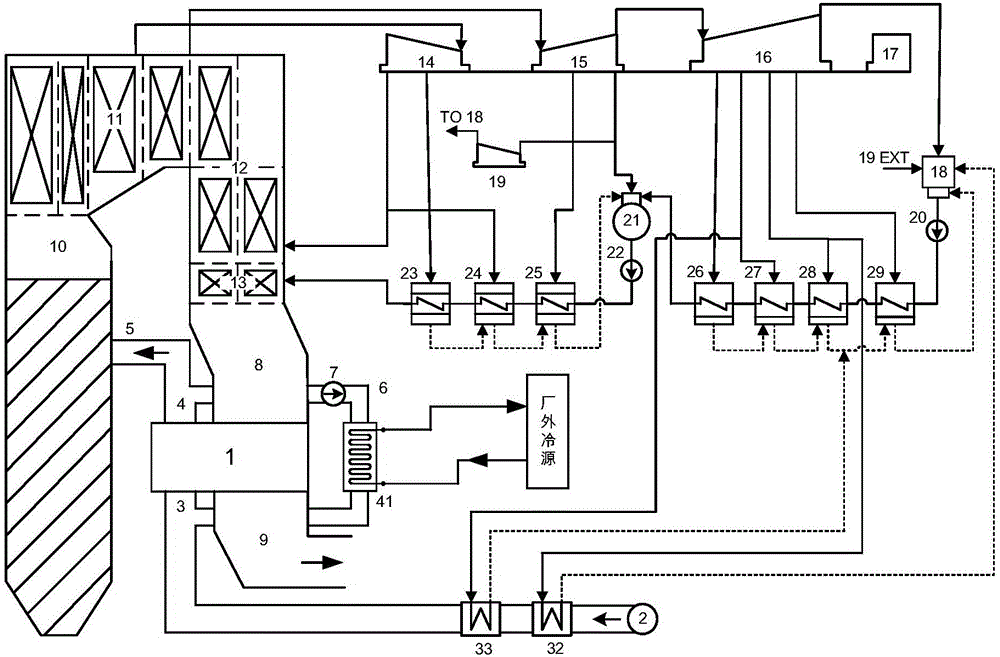

[0031] The present invention proposes a coal-fired power station energy level matching heat integration system around the primary wind, such as figure 1 shown, including:

[0032] Furnace 10, superheater 11, reheater 12, and economizer 13 are sequentially connected in the boiler; economizer 13 is connected to air preheater 1 through air preheater inlet flue 8, and air preheater outlet flue Road 9 is connected to the electrostatic precipitator;

[0033] The first high-pressure heater 23 and the second high-pressure heater 24 are respectively connected to the high-pressure cylinder 14 of the steam turbine;

[0034] The third high-pressure heater 25 and the deaerator 21 are respectively connected to the medium-pressure cylinder 15 of the steam turbine;

[0035] The first low-pressure heater 26, the second low-pressure heater 27, the third low-pressure heater 28, the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com