System and method for rapidly conveying and processing matched gangue at rear part of coal mine rock tunnel integrated excavator

A rapid transportation and disposal system technology, applied in the direction of transportation and packaging, transportation passenger cars, mining equipment, etc., can solve the problems of large manpower consumption, material resources, slow transportation speed, storage ground pollution, etc., to improve unloading efficiency and production efficiency , Improve the effect of tunneling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

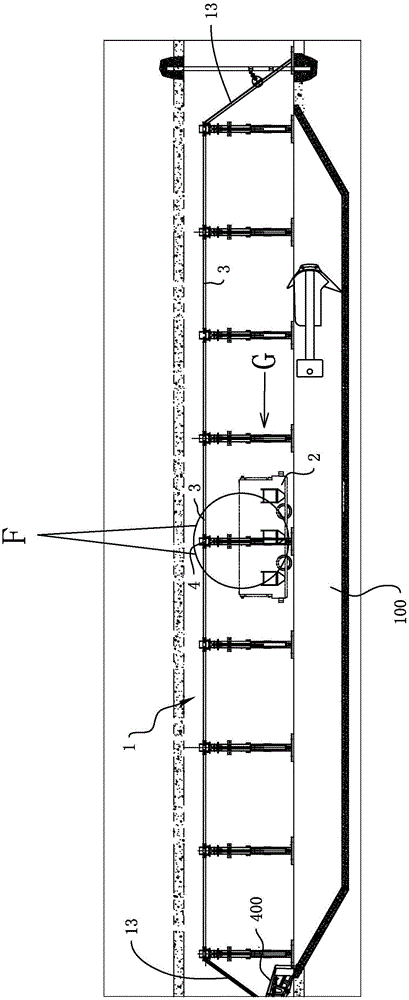

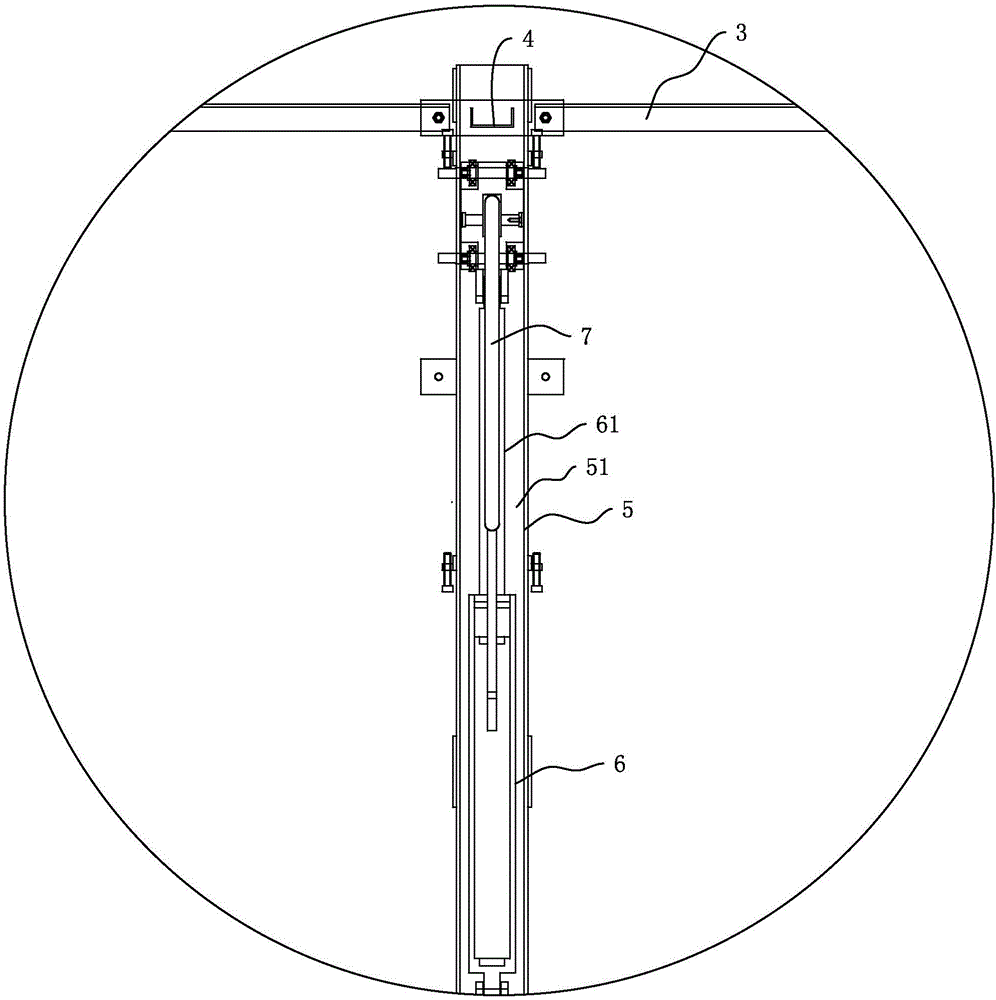

[0030] Such as figure 1 , 2 As shown, the gangue rapid transportation and disposal system for the back of the fully mechanized roadway excavator in the coal mine and rock roadway of the present invention includes a side-unloading mine car 2 and a car unloading device 1 located at the tail of the roadheader and towed by a battery locomotive. A plurality of mine cars 2 form a train, one side of the train is provided with a car unloading device 1 , and a trough-type horizontal gangue storage bin 100 is excavated below the car unloading device 1 . combine Figure 4 As shown, a scraper loader 400 is installed at one end of the gangue storage bin 100, and the scraper loader 400 is connected to the crusher 600 through the lump gangue belt conveyor 500. combine Figure 5 , Figure 6 As shown, the crusher 600 is connected to the mixer 800 through the crushing belt conveyor 700, and the mixer 800 is also connected to a concrete delivery pump 900. combine Figure 7 As shown, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com