New concrete production technology

A production process and concrete technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc., can solve the problems of poor compatibility between cement and admixtures, uneven distribution of powdery materials, etc., and achieve real-time effective automatic control , The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the examples.

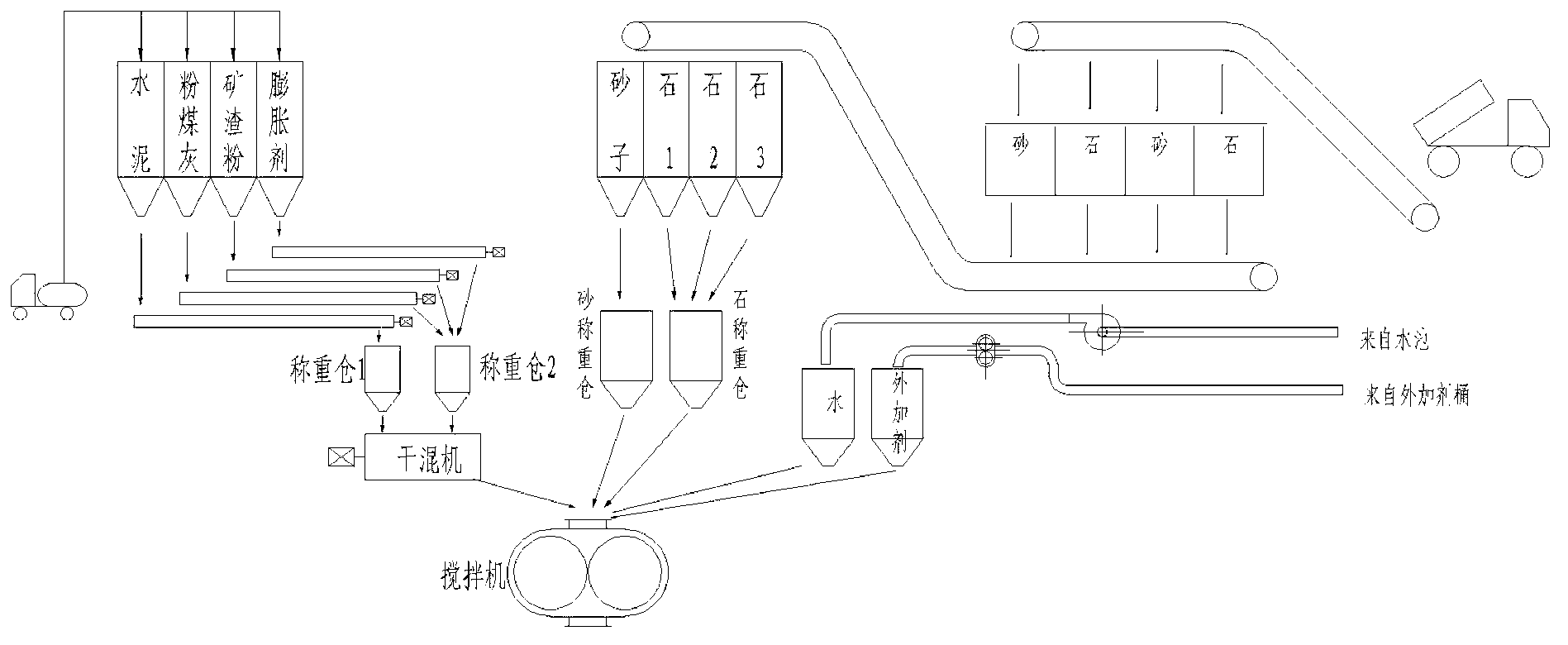

[0022] The traditional concrete production process is to put sand, stone, cement, admixture, water and admixtures into the mixer for mixing. Discharge after stirring evenly, the feeding combination and sequence are as follows: figure 1 shown.

[0023] The production process of the present invention strictly controls the feeding, batching, stirring and unloading of various materials according to a certain combination, sequence and time, such as figure 2 As shown, it includes the following steps: (1) Primary batching dry mixing slurry: According to the mixing ratio requirements of concrete of different strength grades, the cement, admixture, expansion agent and other powder materials are measured separately and then unloaded into a special fine powder mixer at the same time. After mixing evenly, unload it into the mixer, add sand and part of water according to the propor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com