Reverse feed high-aromatic-hydrocarbon hydro-upgrading method

A technology of reverse feeding and hydrogenation upgrading, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problems of increasing system scale, long pipeline system, and large number of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

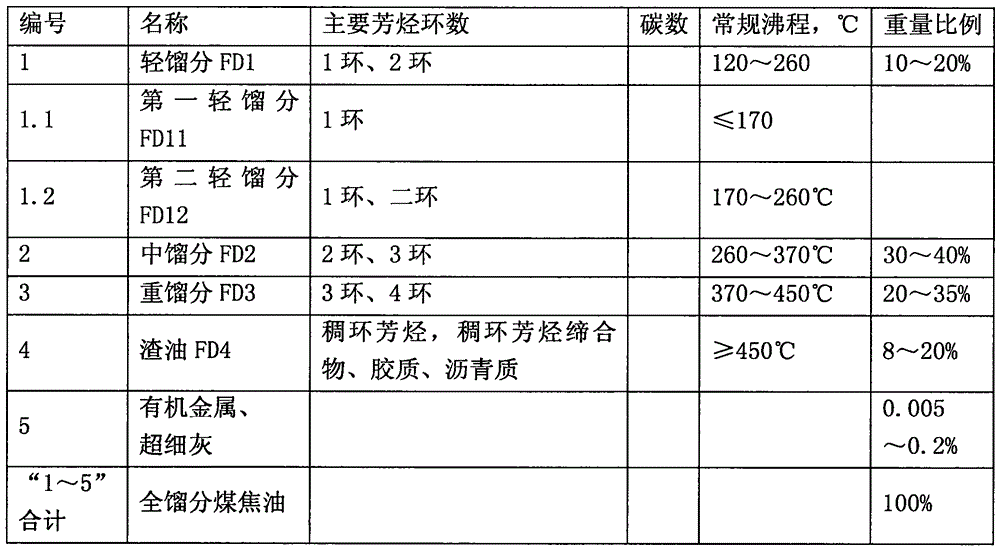

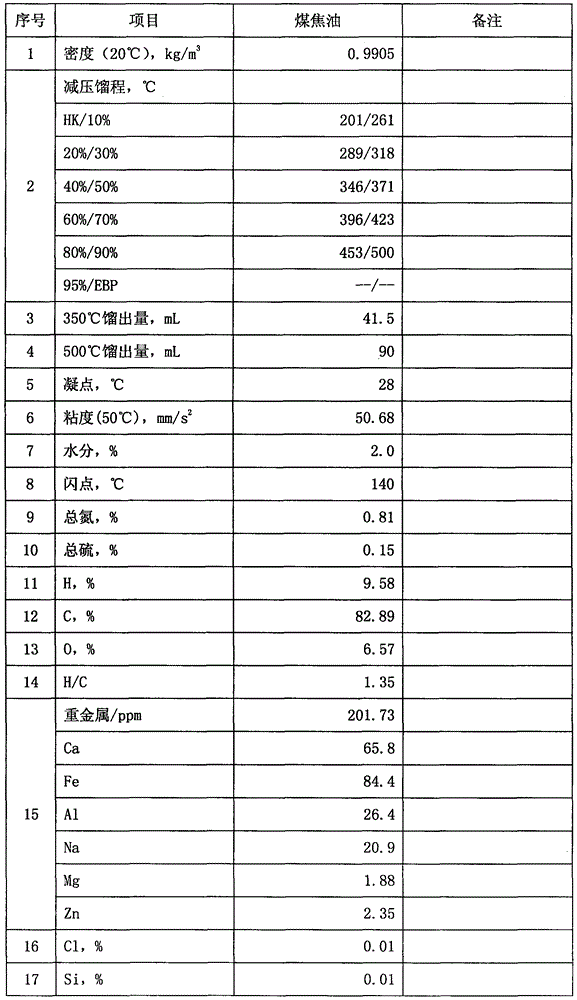

[0526] Based on the medium temperature coal tar in Table 3, using the process of the present invention, its operation objectives are:

[0527] ① After removing the high residual carbon and high impurity components with the conventional boiling point higher than 350℃ in the medium temperature coal tar, it enters the first hydrogenation reaction process using the fluidized bed hydrothermal cracking process R10;

[0528] The first hydrogenation reaction process R10 is operated by the method described in Chinese patent application CN104593060A; 2 sets of fluidized bed hydrothermal cracking reactors operated in series are set up; each fluidized bed hydrothermal cracking reactor is equipped with forced internal circulation of liquid products ; According to needs, each fluidized bed hydrothermal cracking reactor can discharge part of the liquid hydrocarbon oil as a liquid product, and can also be used to prevent the accumulation of fused ring aromatics in the fluidized bed hydrothermal cr...

Embodiment 2

[0543] The analysis data of medium temperature coal tar is shown in Table 3. According to the present invention, the combined hydro-upgrading process after high-pressure gas stripping and separation includes the following steps:

[0544] ①In the first hydrogenation reaction process R10, in the presence of hydrogen and the first hydrogenation reaction catalyst R10C, the hydrocarbons from step ② are mainly composed of hydrocarbon components with a conventional boiling point higher than 350°C, with high residual carbon components The raw material R10F enters the first hydrogenation reaction process R10 to perform the first hydrogenation reaction R10R to obtain the first hydrogenation reaction effluent R10P;

[0545] Hydrocarbon feedstock R10F, containing tricyclic aromatic hydrocarbons and polycyclic aromatic hydrocarbons;

[0546] The first hydrogenation reaction R10R includes a hydrorefining reaction and a hydrocracking reaction;

[0547] The first hydrogenation reaction process R10 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com