Liquid dye for active ink and preparation method and application thereof

A technology of liquid dyes and reactive inks, applied in applications, organic dyes, inks, etc., can solve problems such as poor stability, and achieve high stability, good printing effect, color fixation rate and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

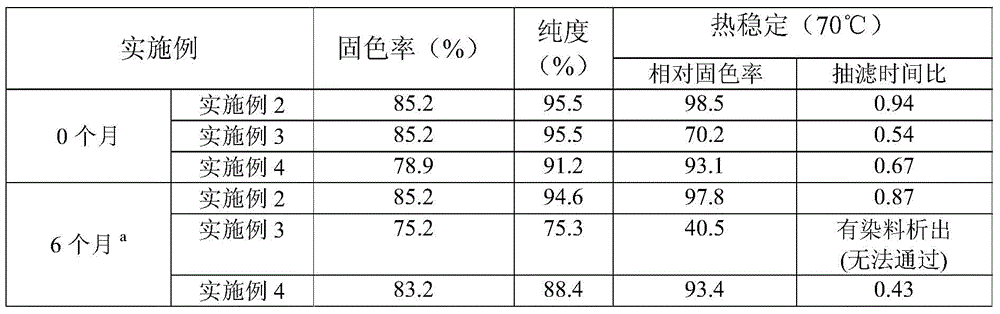

Examples

Embodiment 1

[0031] Example 1: Preparation of synthetic puree of active orange 13

[0032] (1) Disperse N-methyl J acid in water, stir for 15 minutes, adjust pH to 7.1-7.3 with industrial liquid alkali, and obtain clear liquid after dissolving. Add maleic anhydride dropwise to the clear solution, adjust the pH to 7.0-7.5 with industrial liquid alkali again, add ice to control the reaction at 30°C for 3 hours, cool down to 20-25°C, and obtain an acylated solution for later use. In this step , the molar ratio of N-methyl J acid and maleic anhydride is 1:1.1, and the amount of water used is 5 times the mass of N-methyl J acid.

[0033] (2) add ice water in the diazo reaction pot and put into sulfonated toubic acid for beating for 1 hour, add hydrochloric acid and stir for 15 minutes, slowly add sodium nitrite solution, control temperature≤5℃, after the test end point is reached, obtain diazonium salt for later use , the molar ratio of sulfonated tuyere acid, hydrochloric acid and sodium nitr...

Embodiment 2

[0037] The preparation of embodiment 2 active ink

[0038](1) the active orange 13# synthetic puree obtained in Example 1 was adjusted to pH 7.5-8.0 with hydrochloric acid, then left standstill for 24 hours at room temperature, and then filtered to obtain a filtrate;

[0039] (2) the filtrate obtained in step (1) is warmed to 50 ° C, then sodium chloride is added to carry out salting out, wherein, the quality of sodium chloride is 1.2 times of the dry weight of the dye stock, and the salting-out precipitate is obtained by pressure filtration filter cake;

[0040] (3) at a temperature of 25° C., add water to the filter cake obtained in step (2) for beating, wherein the consumption of the filter cake and water is 1 g: 7.5 mL, and the pulp amount is added in the beating liquid to reduce the total amount of activated carbon to 3%. The dosage is adsorbed, and the pH value is maintained at 7.5-8.5 for 12 to 24 hours. If there is no obvious change, the filter press is used for press...

Embodiment 3

[0045] In this example, step (1) after adjusting the pH to 6.0-7.0, it was left to stand still, and other operations were exactly the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com