A high-temperature-resistant full-suspension low-damage fracturing fluid and its preparation method

A full-suspension, fracturing fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of sand-carrying performance that have not been disclosed or elaborated in detail, and achieve excellent sand-carrying performance and strong shear recovery , Improve the effect of transformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-temperature-resistant full-suspension low-damage fracturing fluid system, based on 100 parts by weight, the content of each component is as follows:

[0039]0.3-0.5 parts of low-harm thickener, 0.1-0.4 parts of multi-functional stabilizer; 0.1-0.3 parts of regulator; 0.4-0.8 parts of suspension synergist, and the remaining components are clear water or salt water within a certain salinity range .

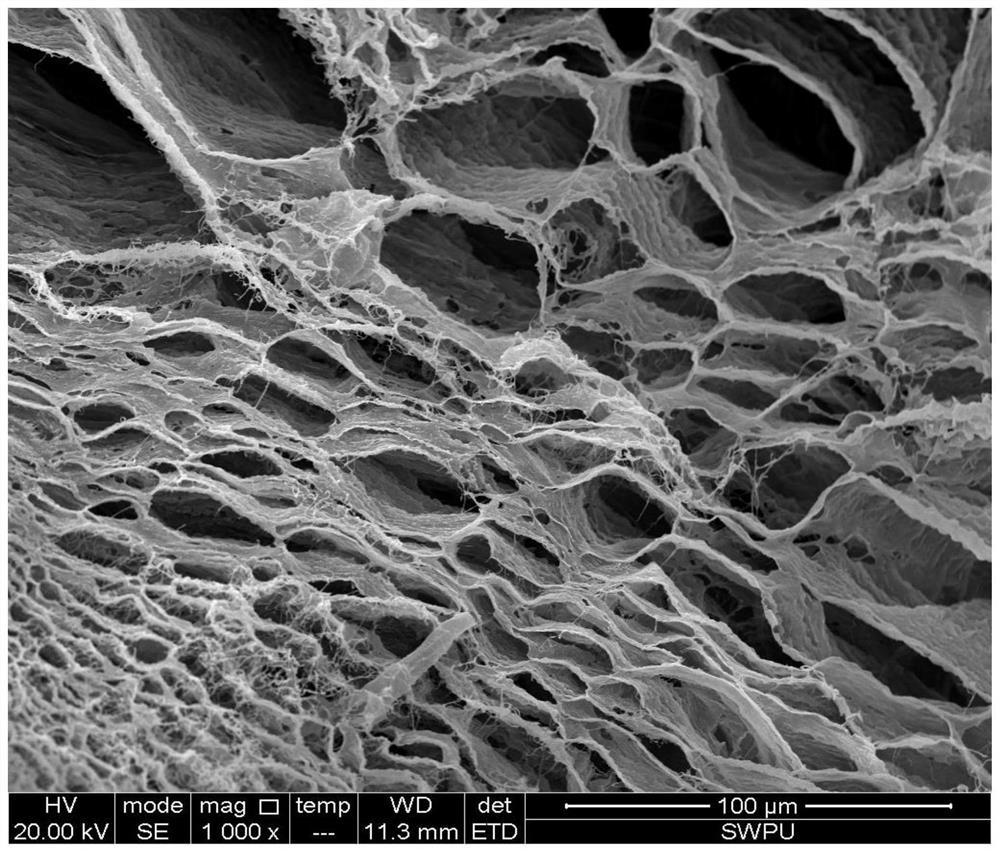

[0040] Among them, the low-harm thickener consists of the main chain monomer A acrylamide, the main chain monomer B sodium acrylate, the salt-tolerant monomer 2-acrylamido-2-phenylethanesulfonic acid and N-allylimidazole, etc. It is formed by the polymerization reaction of N-vinyl caprolactam, a mixture of cross-linking monomers. The thickener is produced by Chengdu Baichun Petroleum Technology Co., Ltd., the product code is BCG-1XF-1, the product is <80 mesh white granules or powder, and the apparent molecular weight is 2 million to 3 million. Further, the basic perf...

Embodiment 2

[0050] A high-temperature-resistant full-suspension low-damage fracturing fluid system, based on 100 parts by weight, the content of each component is as follows:

[0051] Low-harm thickener, 0.3-0.5 parts, multi-functional stabilizer, 0.1-0.4 parts; conditioner, 0.1-0.3 parts; suspension synergist, 0.4-0.8 parts, and the remaining components are clear water or within a certain salinity range brine.

[0052] Among them, the low-harm thickener consists of a mixture of main chain monomer A acrylamide, main chain monomer B acrylic acid, salt-tolerant monomer N-vinylpyrrolidone and N-allylimidazole, etc. Composition of acetone acrylamide. The thickener is produced by Chengdu Baichun Petroleum Technology Co., Ltd., the product code is BCG-1XF-2, and the basic performance index achieved is the same as that of Example 1.

[0053] The multifunctional stabilizer is produced by Chengdu Baichun Petroleum Company. The product code is BC-5-1. The product is a colorless or light yellow tr...

Embodiment 3

[0061] A high-temperature-resistant full-suspension low-damage fracturing fluid system, based on 100 parts by weight, the content of each component is as follows:

[0062] Low-harm thickener, 0.3-0.5 parts, multi-functional stabilizer, 0.1-0.4 parts; conditioner, 0.1-0.3 parts; suspension synergist, 0.4-0.8 parts, and the remaining components are clear water or within a certain salinity range brine.

[0063] Among them, the low-harm thickener consists of a mixture of the main chain monomer A acrylamide, the main chain monomer B acrylic acid, the salt-tolerant monomer N-allylimidazole and vinylphosphonic acid, and the cross-linking monomer It is prepared by polymerization of diacetone acrylamide. The thickener is produced by Chengdu Baichun Petroleum Technology Co., Ltd., the product code is BCG-1XF-3, and the basic performance index achieved is the same as that of Example 1.

[0064] Multifunctional stabilizer BC-5-2, the product is a colorless or light yellow transparent li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com