Concrete based on micro-nano powder and preparation method of concrete

A concrete, micro-nano technology, applied in the field of building materials, can solve the problems of large specific surface energy, secondary agglomeration, poor durability, etc., achieve uniform strength distribution, compensate for self-shrinkage, and improve durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

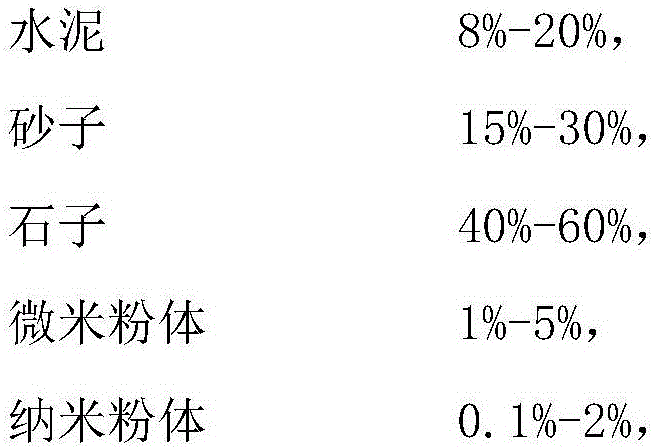

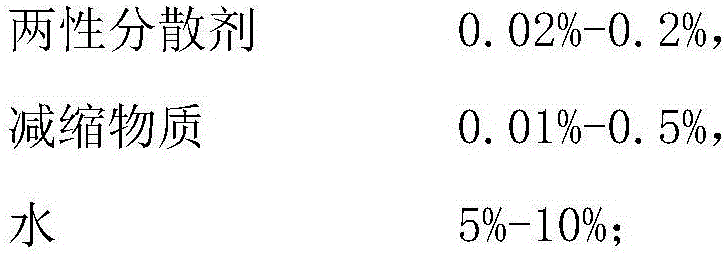

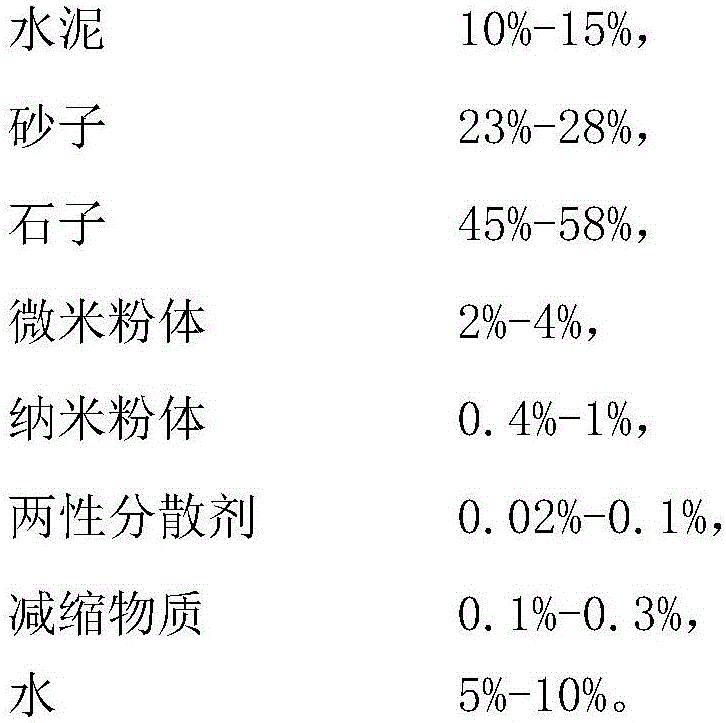

Method used

Image

Examples

Embodiment 1

[0036] In parts by weight, the raw materials are prepared according to the following formula: 1 part of acrylic acid, 0.5 part of acryloyloxyethyltrimethylammonium chloride, 25 parts of allyl polyoxyethylene ether, 0.01 part of ammonium persulfate, 0.01 part of ascorbic acid, 0.01 part of thioglycolic acid, 40 parts of water;

[0037] Mix 1 part of acrylic acid, 0.01 part of thioglycolic acid and 4 parts of water to obtain the second mixture, mix 0.5 parts of acryloyloxyethyltrimethylammonium chloride and 4.5 parts of water to obtain acryloyloxyethyltrimethylammonium chloride Solution, 0.01 part of ascorbic acid and 0.2 part of water are mixed to obtain ascorbic acid solution;

[0038] Put 25 parts of allyl polyoxyethylene ether, 0.01 part of ammonium persulfate and 31.3 parts of water into the reaction kettle, and mix to obtain the first mixture. When the temperature of the above-mentioned first mixture is controlled at 25°C, add Add the second mixture, the acryloyloxyethylt...

Embodiment 2

[0042] In parts by weight, prepare raw materials according to the following formula: 8 parts of methacrylic acid, 4 parts of acryloyloxyethyltrimethylammonium chloride, 45 parts of methallyl polyoxyethylene ether, 1.5 parts of ammonium persulfate, 1 part of ascorbic acid, 0.5 part of thioglycolic acid, 70 parts of water;

[0043] Mix 8 parts of methacrylic acid, 0.5 parts of thioglycolic acid and 15 parts of water to obtain the second mixture, and combine 4 parts of acryloyloxyethyltrimethylammonium chloride with 18 parts of water to obtain acryloyloxyethyltrimethylchloride Ammonium chloride solution, 1 part of ascorbic acid and 12 parts of water are mixed to obtain ascorbic acid solution;

[0044] Put 45 parts of methallyl polyoxyethylene ether, 1.5 parts of ammonium persulfate and 25 parts of water into the reactor, and mix to obtain the first mixture. When the temperature of the above-mentioned first mixture is controlled at 50°C, add Add the second mixture, the acryloylox...

Embodiment 3

[0048]In parts by weight, prepare raw materials according to the following formula: 4 parts of acrylic acid, 2 parts of acryloyloxyethyltrimethylammonium chloride, 40 parts of prenol polyoxyethylene ether, 0.25 part of hydrogen peroxide, 0.25 part of ascorbic acid , 0.1 part of thioglycolic acid, 53.4 parts of water;

[0049] Mix 4 parts of acrylic acid, 0.1 part of thioglycolic acid and 10 parts of water to obtain the second mixture, mix 2 parts of acryloyloxyethyltrimethylammonium chloride with 12 parts of water , mix 0.1 part of ascorbic acid with 2 parts of water to obtain ascorbic acid solution;

[0050] Add the above-mentioned 40 parts of isopentenol polyoxyethylene ether, 0.25 parts of hydrogen peroxide and 29.4 parts of water into the reaction kettle to obtain the first mixture, start stirring and heating, and when the temperature of the above-mentioned first mixture rises to 30 ° C, add to the reactor. The above-mentioned second mixture, the above-mentioned acryloylo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com