Three-dimensionally-woven composite automotive transmission shaft and manufacturing method of three-dimensionally-woven composite automotive transmission shaft

A technology of three-dimensional weaving and composite materials, applied in the direction of shafts, couplings, mechanical equipment, etc., can solve the problems of low stiffness life stability, high fuel consumption, heavy weight, etc., to improve the safety of use and fuel efficiency, reduce The effect of vehicle running vibration and reducing transmission noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

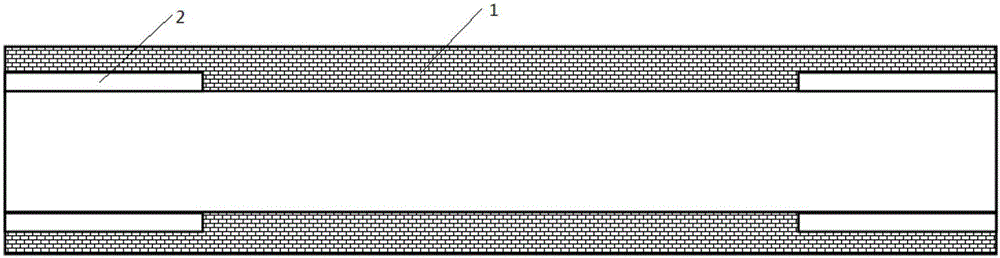

[0041] A three-dimensional braided composite automobile transmission shaft, comprising a three-dimensional braided composite material transmission shaft tube 1, a three-dimensional braided composite material universal joint and a three-dimensional braided composite material connecting sleeve 6;

[0042] Such as figure 1 and figure 2 As shown, the two ends of the three-dimensional braided composite material transmission shaft tube 1 are provided with several first inner sliding spline grooves 2, and the three-dimensional braided composite material transmission shaft tube is a three-dimensional three-dimensional structure made of high-rigidity fibers. The braided prefabricated body, the secondary seam-laying structure along the thickness direction of the prefabricated body at the position of the first inner sliding spline groove 2 in the three-dimensional braided prefabricated body, and thermosetting resin composite molding;

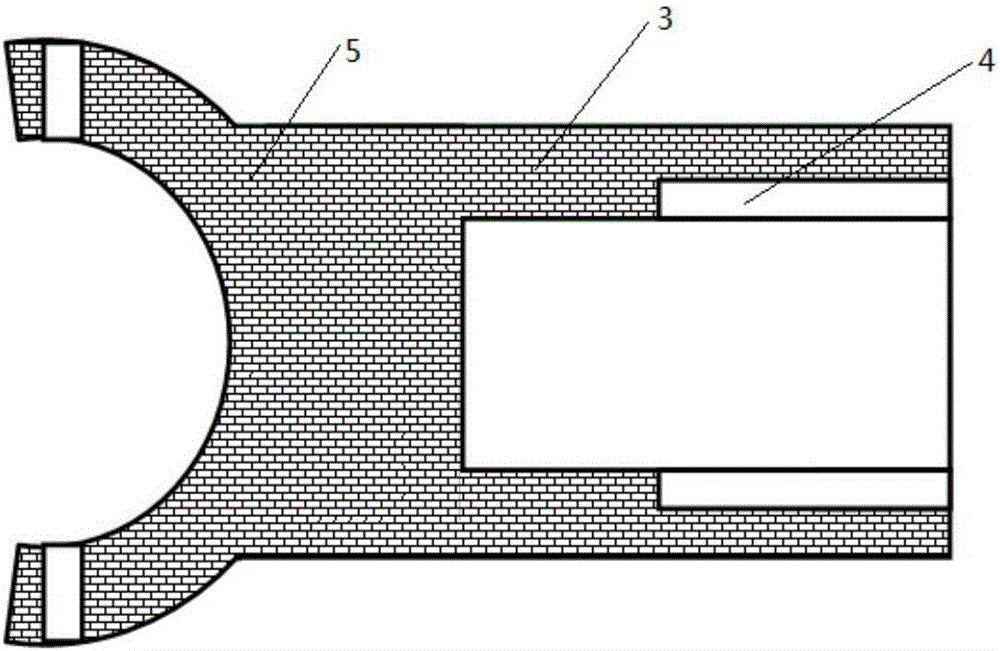

[0043] Such as image 3 and Figure 4 As shown, ...

Embodiment 2

[0058] The preparation of the three-dimensional braided composite material automobile transmission shaft designed by the present invention comprises the following steps:

[0059] First, the preparation of three-dimensional braided composite transmission shaft tube preform. The mixed combination of M60J high modulus carbon fiber and alumina fiber is used as the prefabricated weaving filament, and the mixing ratio of carbon fiber and alumina fiber is 6:1. There is a first sliding spline groove inside the two ends of the shaft tube, and the position of the first sliding spline groove is formed by a three-dimensional six-direction weaving process to prepare for connection with other parts. The thickness of the prefabricated fabric at the spline groove is made of high-strength T300 The carbon fiber is reinforced by secondary seam laying, and the proportion of seam laying reinforcement fiber accounts for 10% of the overall fiber of the three-dimensional fabric prefabricated body of ...

Embodiment 3

[0071] The preparation of the three-dimensional braided composite material automobile transmission shaft designed by the present invention comprises the following steps:

[0072] First, the preparation of three-dimensional braided composite transmission shaft tube preform. The mixed combination of M40J high modulus carbon fiber and basalt fiber is used as the prefabricated weaving filament. The mixed ratio of carbon fiber and basalt fiber is 1:1. There is a first sliding spline groove inside the two ends, and the position of the first sliding spline groove is formed by a three-dimensional six-direction weaving process to prepare for connection with other parts. Secondary seam-laying reinforcement, the proportion of seam-laying reinforcement fiber accounts for 13% of the overall fiber of the three-dimensional fabric prefabricated body of the transmission shaft tube.

[0073] Second, the preparation of the three-dimensional braided composite universal joint prefabricated body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com