3 D printing equipment and material supplying stirring system based on 3 D printing

A 3D printing and stirring system technology, applied in the field of 3D printing, can solve the problem of easy blocking of the nozzle, and achieve the effect of ensuring uniform transportation, overcoming easy blocking, and preventing material from settling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

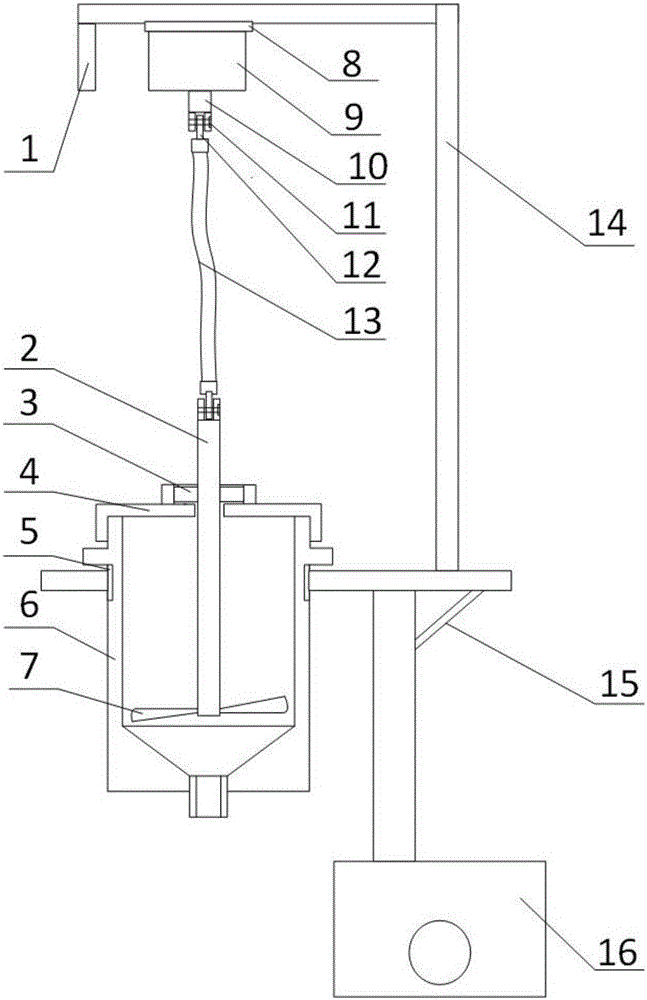

[0033] In order to have a clearer understanding of the technical features, objects and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0034] like figure 1 As shown, the present invention proposes a kind of 3D printing equipment, and described 3D printing equipment comprises:

[0035] The material tank 6 is used to accommodate the materials required for 3D printing, such as materials for low-temperature deposition 3D printing; the materials of the materials are: polylactic acid-glycolic acid copolymer (PLGA), and tricalcium phosphate (TCP), and / or (high-purity) magnesium powder (Mg, the purity of magnesium is, for example, 99.97%) to form a composite material, the above-mentioned PLGA, TCP and / or Mg are passed through an organic solvent (for example, 1,4-dioxane, or three Chloromethane, etc.) to form a fluid, the fluid comes out from the discharge port and / or nozzle to print out a preliminary shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com