Fiberboard manufacturing method

A manufacturing method and fiberboard technology, which are applied in the field of fiberboard manufacturing, can solve the problems of poor wear resistance, irreparable sheet materials, and high formaldehyde content, and achieve the effects of improving flatness, avoiding non-waterproof and high flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

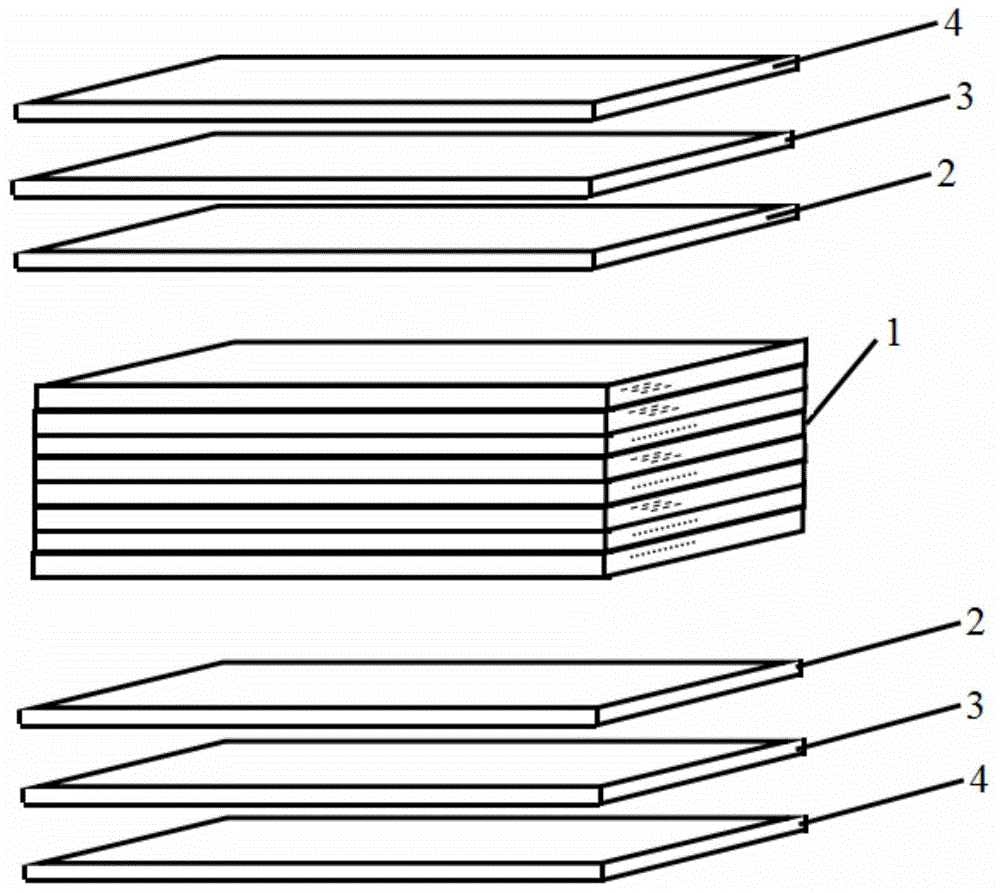

Image

Examples

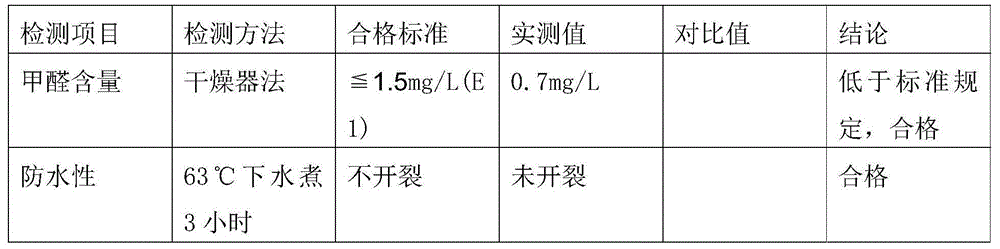

Embodiment 1

[0035]Adjust the alkali lignin with sulfuric acid to a pH value of 2.0 to form an insoluble precipitate, plate and frame press filter, dry, and finally pulverize into a powder with a mesh number of 90-250 mesh to obtain the alkali lignin extracted by acidification; Mix and stir the alkali lignin extracted by acidification and urea-formaldehyde resin adhesive with a weight ratio of 5:100, and finally prepare the waterproof adhesive for the fiberboard layer. Then mix 1 part of fiberboard layer waterproof glue for every 5 parts of fiber glue to make it thin. Among them, viscose is reacted by urea and formaldehyde in a weight ratio of 4:6, heated up at 90 and kept for one hour, then added 20% formic acid, reacted for 1 hour, and then added 30% NaOH to make the pH value reach 5.0, React for one hour to obtain the intermediate, then add 15% urea in an amount of 10 parts by weight of urea per 100 parts by weight of the intermediate, react for 20 minutes, and stop the reaction to form...

Embodiment 2

[0040] Adjust the pH value in Example 1 to about 1.5 or 2.5, and basically satisfactory results can still be obtained after testing.

Embodiment 3

[0042] The ratio of acidified extracted alkali lignin and urea-formaldehyde resin adhesive in Example 1 is adjusted to 4:100 or 6:100, and basically satisfactory results can be obtained through testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com