A high-frequency longitudinal-torsion composite vibrating sponge array strip-taking workbench and its application

A composite vibration and worktable technology, applied in metal processing and other directions, can solve the problems of low product accuracy, low automation, and low processing efficiency of the elastomer layer, and achieve high aperture dimensional accuracy, stable strip removal process, and automated processing significance. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

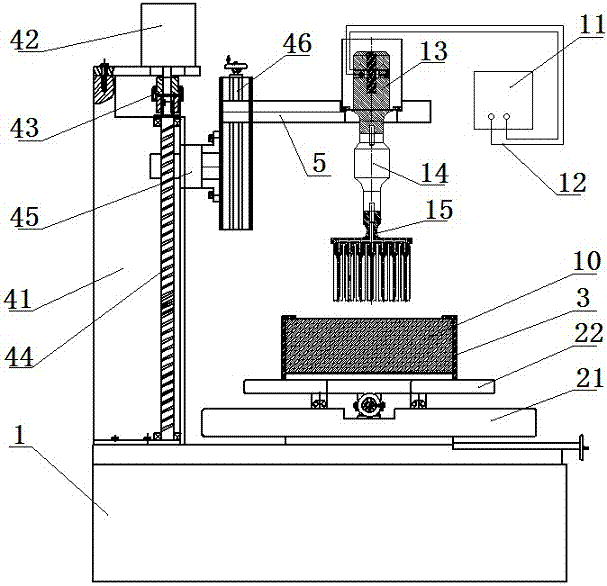

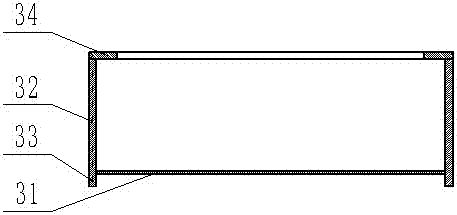

[0054] Such as figure 1 As shown, the horizontal movement mechanism includes a longitudinal movement platform 21 and a transverse movement platform 22. The longitudinal movement platform 21 driven by a ball screw is connected to the base 1 by bolts, and the transverse movement platform 22 driven by a ball screw is connected by a bolt. The connection is arranged on the longitudinal movement platform 21, and the fixed frame 3 is arranged on the transverse movement platform 22 through the bolt connection. Through the cooperative drive of the longitudinal movement platform 21 and the transverse movement platform 22, the fixed frame 3 drives the workpiece 10 to be processed to realize horizontal and vertical movement. Arbitrary trajectory movement in a composite 2D plane.

[0055] continue to see figure 1 , the high-frequency longitudinal-torsion compound vibration sponge array strip-taking device includes an ultrasonic generator 11, an ultrasonic transducer 13 connected to the ul...

Embodiment 2

[0075] The difference from Embodiment 1 is that the tube body mounting plate 152 also includes a cover 1523 for the internally threaded hole 1522 . It is used for the closure of the internally threaded hole 1522 that is not connected to the pipe body.

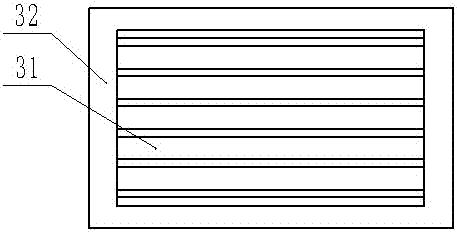

[0076] For example, when the diameter of the elastomer layer of the pre-processed transfer roller is large, such as Figure 8 As shown, the external thread head 1533 of the pipe body matches the internal thread hole 1522, and the cavity 153 matches the size of the pre-processed hole.

[0077] Since the outer diameter of the tube becomes larger, it is impossible to sequentially arrange the tubes on the tube mounting plate 152 , and the unused internal threaded hole 1522 is closed by the cover 1523 .

[0078] Using the processing process described in Embodiment 1, the processing of multiple cylindrical hollow strip blanks-the elastomer layer 23 of the transfer roller can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com