A kind of flexible micro-operation mechanism

An operating mechanism and flexible technology, applied in the field of machinery, can solve the problems affecting the accuracy of the mechanism, the range of motion, and the inaccurate motion direction, and achieve the effect of improving the position space and eliminating nonlinearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with preferred embodiments and accompanying drawings.

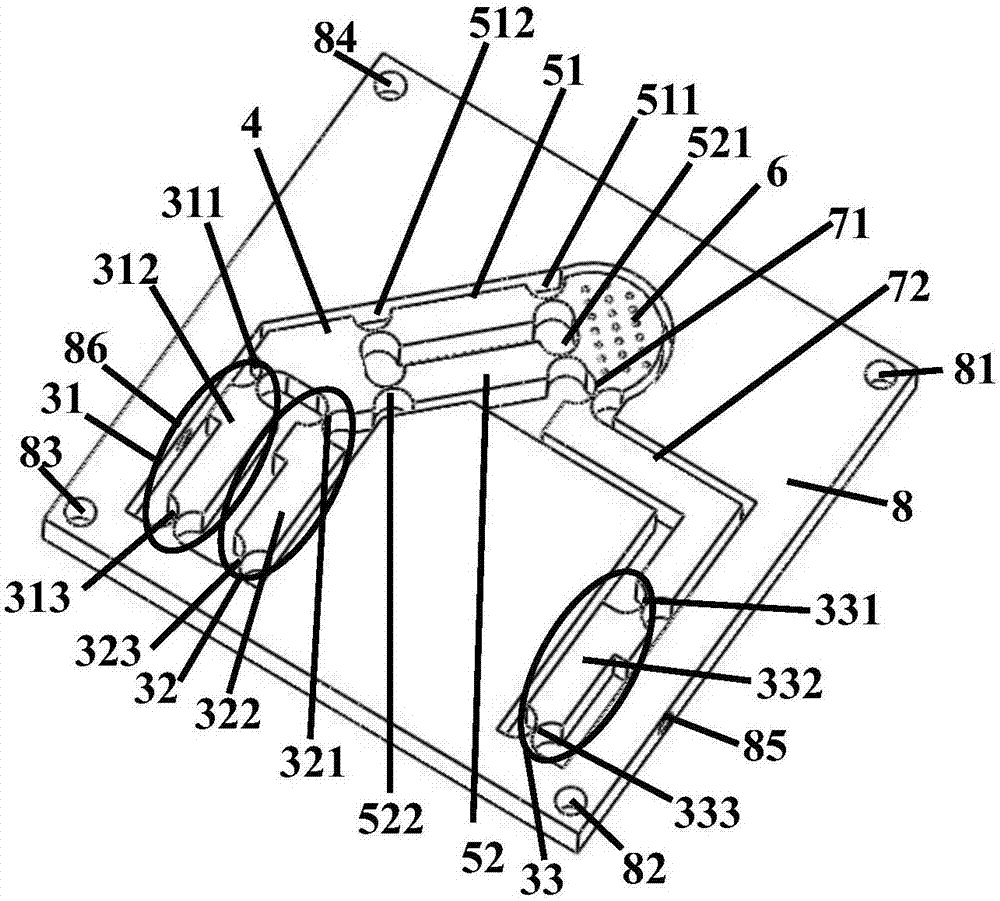

[0022] For the existing flexible micro-operation mechanism based on the five-bar mechanism, one in-plane translational degree of freedom and one in-plane rotational degree of freedom can be realized, and its execution end is generally located on the flexible hinge, which is difficult in actual mechanism design. , the present invention introduces a flexible parallelogram structure and two rigid connecting blocks into the operating mechanism, transforms the rotational degree of freedom of the executing end into a translational degree of freedom, and opens up a special space for the operating end, greatly improving the performance of the mechanism .

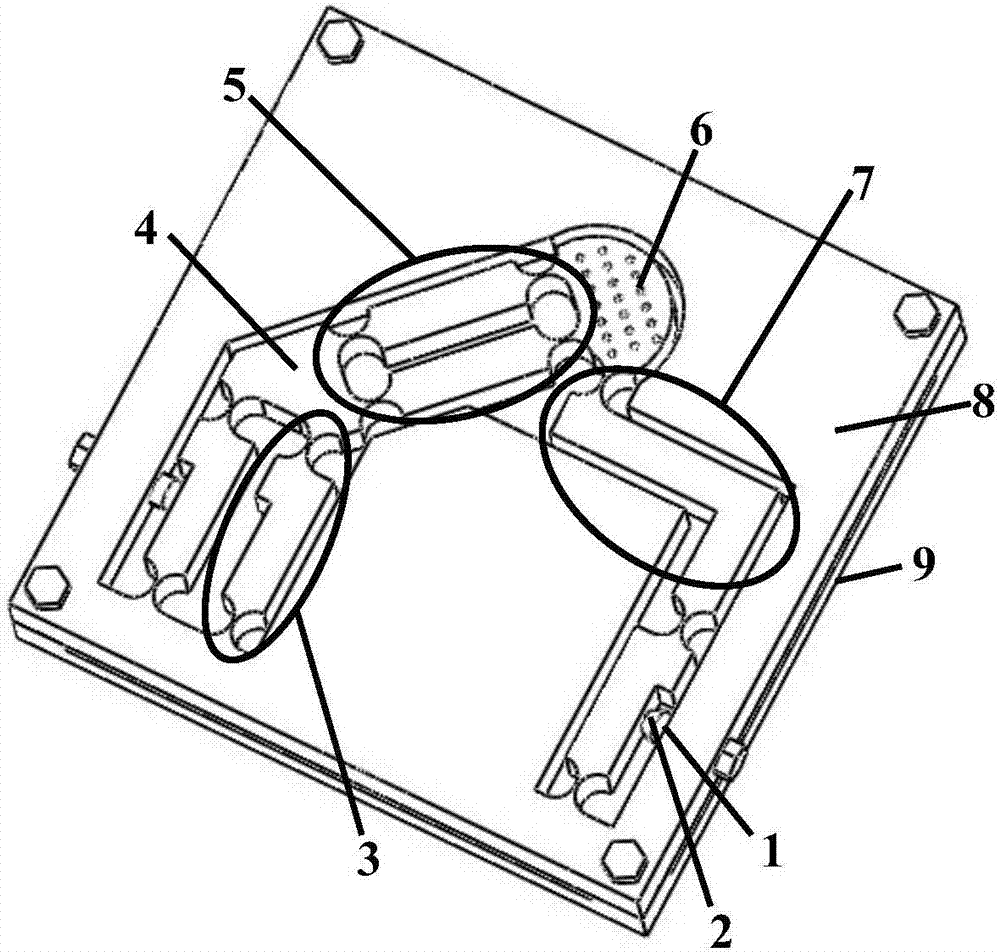

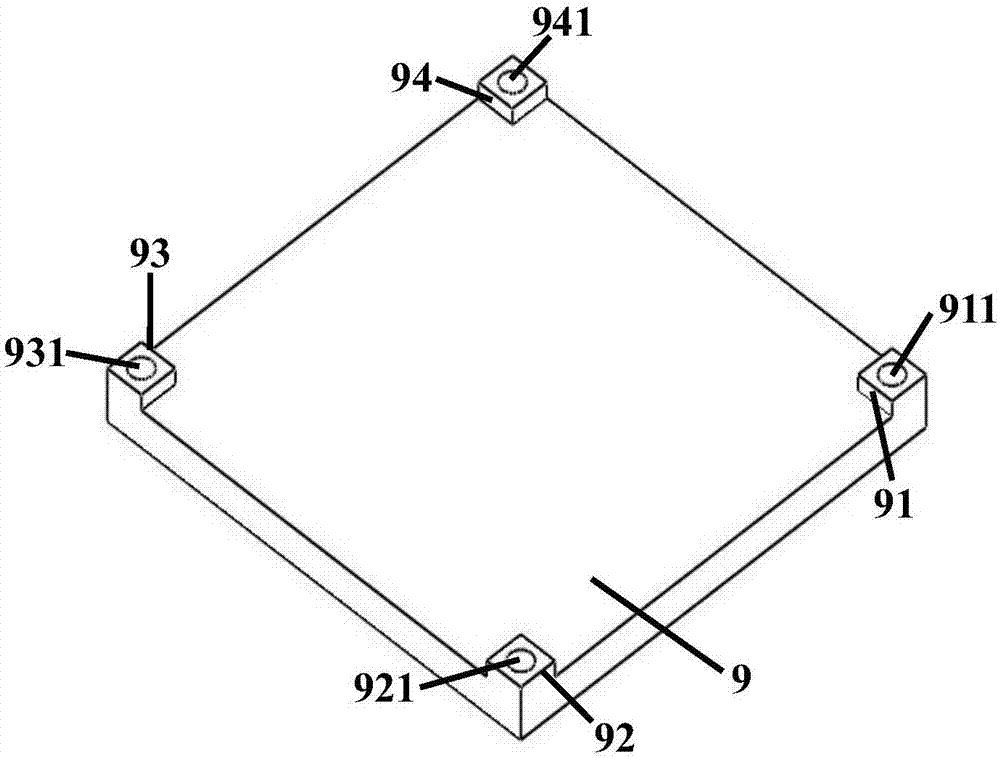

[0023] The flexible micro-operating mechanism designed by the present invention (abbreviated as flexible operating mechanism or mechanism, see Figure 1-4 ) is also based on a five-bar mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com