Two-degree of freedom precise positioning work table

A technology of precise positioning and worktable, applied in the field of micro-operating system, it can solve the problems of uneven distribution of imprinting force, limitation of machining accuracy and quality, and easy stretching and deformation of silica gel. Linear, assembly-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments, structures, features and effects provided according to the present invention will be described in detail below with reference to the accompanying drawings and examples.

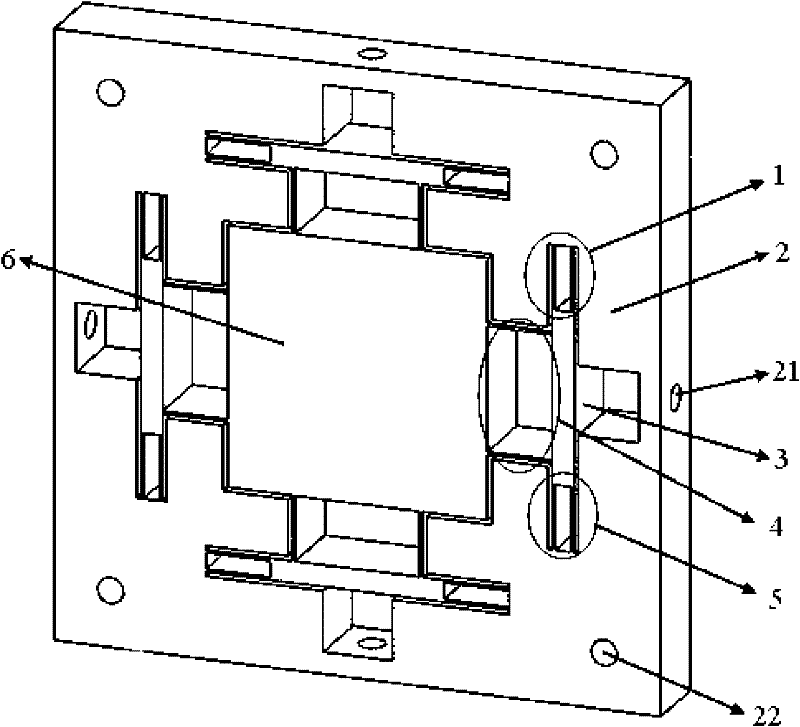

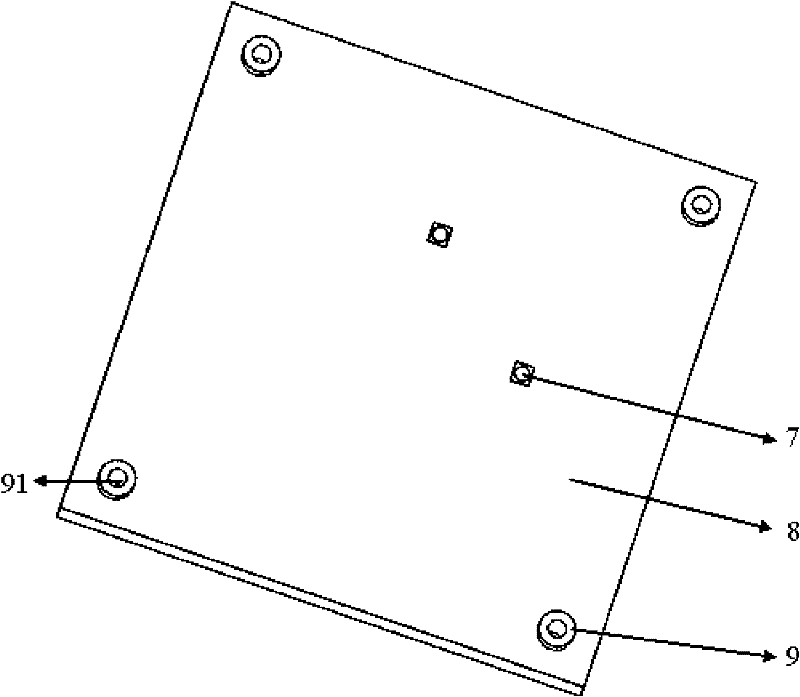

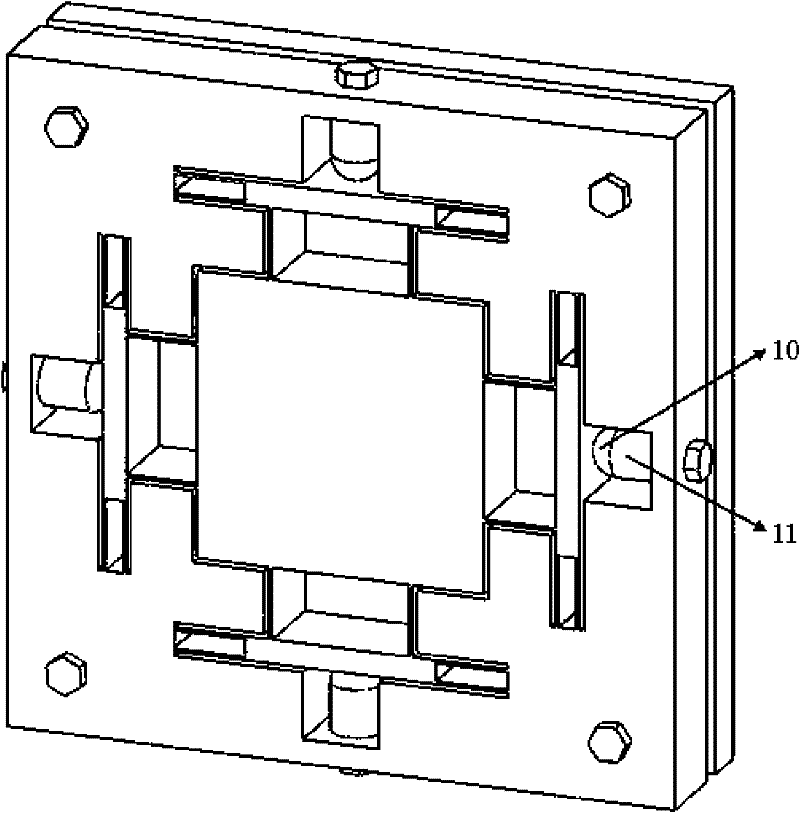

[0020] See Figures 1~4 , a two-degree-of-freedom precision positioning table. This workbench ( image 3) has four piezoceramic drivers 11, and ball joints 10 are installed on the top respectively, through the ball joints 10 contacting with the moving block 3 in a small-area Hertz contact mode, the piezoceramic drivers 11 are horizontally placed, and the two sides of the moving platform 6 The first axis of symmetry is the centerline, and the piezoelectric ceramic drivers 11 are arranged symmetrically around the moving platform 6 up and down and left and right respectively, and the tails are fixed on the base 2 through the holes 21 respectively. The workbench comprises a base 2, a moving platform 6 arranged in the middle of the base, a rigid support 8 connected to the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com