Hydraulic expanding sleeve type tool for gear tooth shape processing

A technology of gear tooth shape and expansion sleeve, which is applied in the direction of gear tooth manufacturing equipment, gear teeth, metal processing equipment, etc., can solve problems such as inner hole deformation, inner hole scratches, machine calls, etc., to improve applicability and increase expansion Size limit, the effect of increasing the expansion size limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

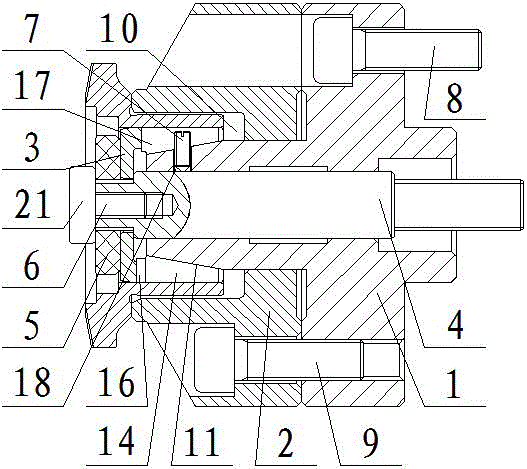

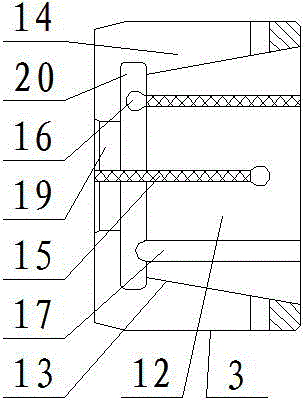

[0028] combine figure 1 and figure 2 As shown, the present invention includes an expansion sleeve positioning base 1, one end of the expansion sleeve positioning base 1 is fixed to the machine tool, and the other end of the expansion sleeve positioning base 1 is fixed with a gear positioning cover 2, and the gear positioning cover 2 faces away from the expansion sleeve. One end of the sleeve positioning base 1 is provided with a gear positioning groove 10. The end of the expansion sleeve positioning base 1 passes through the bottom of the gear positioning groove 10 and is located in the gear positioning groove 10. The expansion sleeve positioning base 1 is located in the gear positioning groove 10. One end of the groove 10 is sleeved with an expansion sleeve 3, and the expansion sleeve positioning base 1 is fixed to one end of the hydraulic pull rod 4 by a screw 6, and the other end of the hydraulic pull rod 4 passes through the set of the expansion sleeve positioning base 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com