Aluminum-coated graphite composite powder, aluminum-graphite composite comprising composite powder and preparation method thereof

A composite powder and composite material technology, applied in transportation and packaging, metal processing equipment, coatings, etc., can solve the problems of chemical copper/nickel plating process limitations on graphite surface, graphite segregation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

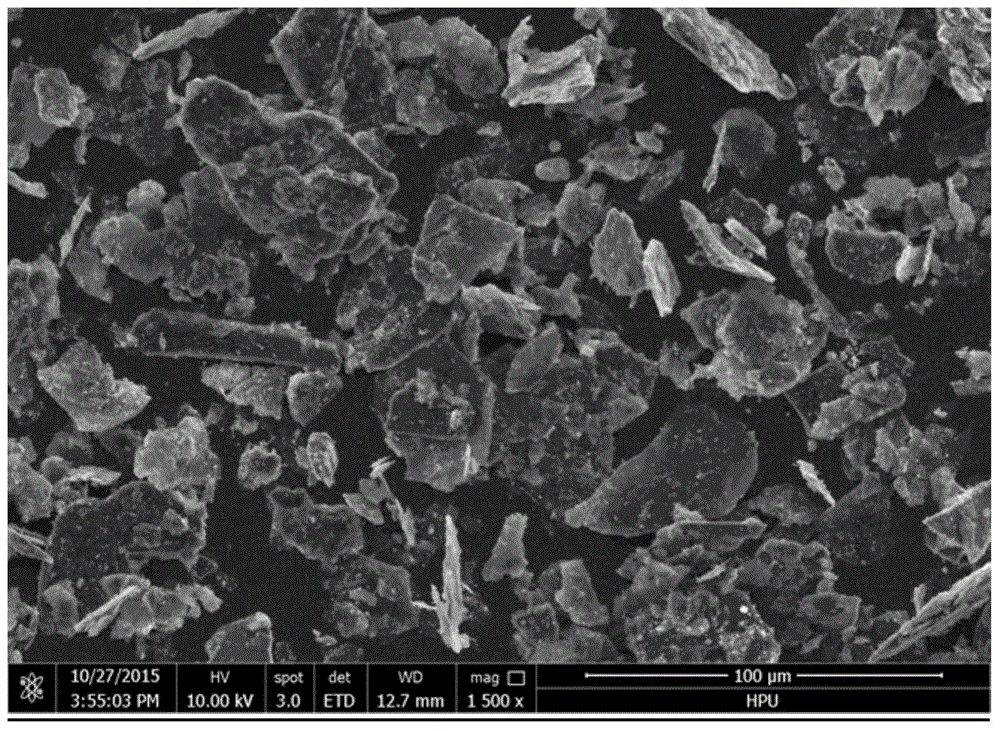

[0069] This embodiment provides an aluminum-coated graphite composite powder, which is prepared by the following steps:

[0070] (1) Raw material selection: choose nano-aluminum powder with a particle size of 80 nanometers as the coating material, and choose graphite with a particle size of 50 microns as the coating core; regard the total integral fraction of nano-aluminum powder and graphite as 100vol%, and nano-aluminum powder The volume fraction of graphite is 60vol%, and the volume fraction of graphite is 40vol%; The quality of binder accounts for the 5wt% of nanometer aluminum powder, graphite and binder total mass, and the proportioning of binder is: epoxy resin: epoxy resin Thinner: ethylenediamine=8:10:3.

[0071](2) After weighing the raw materials according to the mass ratio of step (1), mix the weighed nano-aluminum powder and graphite for 5-10 minutes, then pour the mixed solution of epoxy resin and epoxy thinner, and mix for 5-10 minutes. After 10 minutes, add et...

Embodiment 2

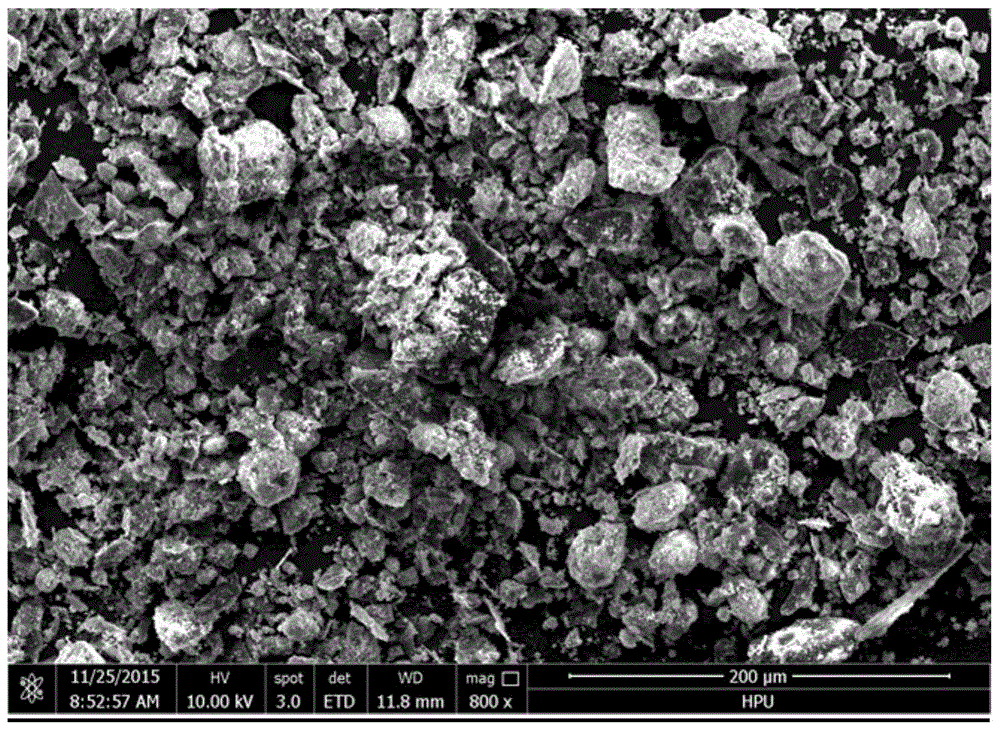

[0076] This embodiment provides an aluminum-graphite composite material. The aluminum substrate of this embodiment is 6061 aluminum with a thickness of 41 to 53 microns, which is prepared by the following steps:

[0077] (1) Using the aluminum-coated graphite composite powder prepared in Example 1 to prepare an aluminum-graphite composite material with a graphite content of 5 vol%, it is necessary to calculate the required quality of 6061 aluminum according to the content of nano-aluminum and graphite.

[0078] (2) Weigh the required raw materials according to the above mass ratio, put the aluminum-coated graphite composite powder and 6061 aluminum particles into the mixer (optional four-barrel aviation star mixer) and mix for 30 minutes to obtain high-pressure sintering raw materials Composite powder.

[0079] (3) Perform high-pressure sintering on the high-pressure sintering raw material composite powder obtained in step 2. The process parameters are: sintering temperature 5...

Embodiment 3

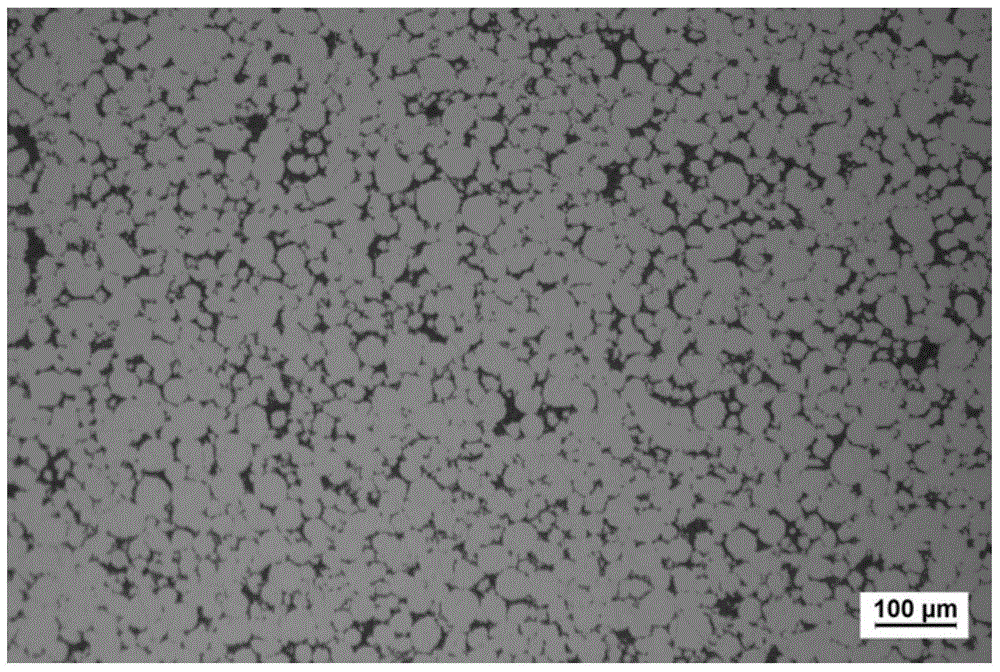

[0082] This embodiment provides an aluminum-graphite composite material. The aluminum substrate of this embodiment is 6061 aluminum with a thickness of 41 to 53 microns, which is prepared by the following steps:

[0083] (1) Using the aluminum-coated graphite composite powder prepared in Example 1 to prepare an aluminum-graphite composite material with a graphite content of 10 vol%, it is necessary to calculate the required mass of 6061 aluminum according to the content of nano-aluminum and graphite.

[0084] (2) Weigh the required raw materials according to the above mass ratio, put the aluminum-coated graphite composite powder and 6061 aluminum particles into the mixer (optional four-barrel aviation star mixer) and mix for 30 minutes to obtain high-pressure sintering raw materials Composite powder.

[0085] (3) Perform high-pressure sintering on the high-pressure sintering raw material composite powder obtained in step 2. The process parameters are: sintering temperature 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com