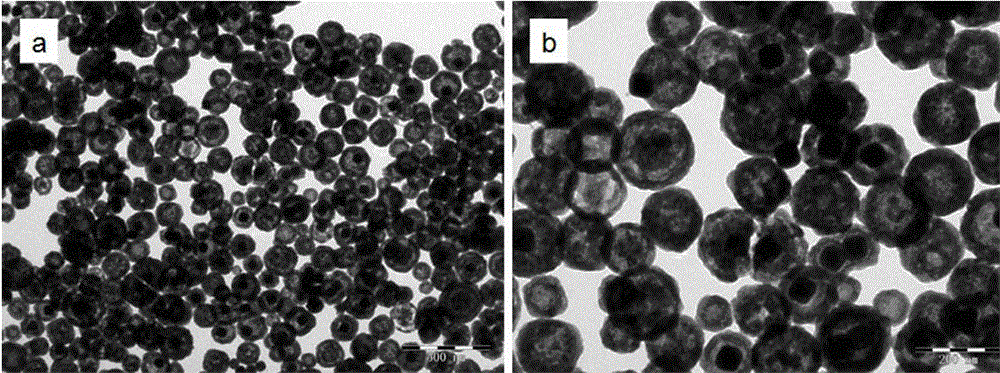

Rapid preparation method of AU@Cu2O nanocomposite in yolk-shell structure

A technology of nanomaterials and eggshells, which is applied in the direction of coating, etc., can solve the problems of difficult nanomaterials, complex preparation methods, cumbersome and lengthy processes, etc., and achieve the effects of good stability, fast preparation process, and simple and easy-to-operate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All reagents used were conventional medicines purchased from reagent companies. Preparation of aqueous solution: 18 megohm deionized water: polydimethyldiallyl ammonium chloride (PDDA, (400,000)) made into 1.25mol / L aqueous solution, chloroauric acid (HAuCl 4 ) into a 1.0mol / L aqueous solution, cetyltrimethylammonium bromide (CTAB) into a 0.2mol / L aqueous solution, and NaOH into a 0.2mol / L aqueous solution.

[0025] The content of the present invention will be further described in detail below in conjunction with specific implementation examples.

[0026] Experimental example

[0027] 1. Preparation of Gold Octahedral Nanoparticles

[0028] Add 1mol / L HAuCl to the glass bottle 4 Solution 35μL, then add 70mL ethylene glycol, then add 1.40mL polydimethyldiallylammonium chloride (PDDA) (400,000, 1.25mol / L), the final concentration of each component in the system: HAuCl 4 : 0.50mmol / L, PDDA: 25mmol / L. After the above solution was fully mixed, it was placed in an oil ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com