Automobile covering part mold manufacturing method

A technology for manufacturing automobile panels and molds, applied in the field of production and manufacturing, can solve the problems of long production cycle, lower production cost, and high cost, and achieve the effect of shortening the manufacturing cycle and reducing production cost

Inactive Publication Date: 2016-06-22

CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

View PDF4 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The invention provides a method for manufacturing an automobile panel mold, which solves the technical problems of long production cycle and high cost in the existing automobile panel mold manufacturing, shortens the manufacturing cycle of the automobile panel mold, and reduces the production cost. technical effect of cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

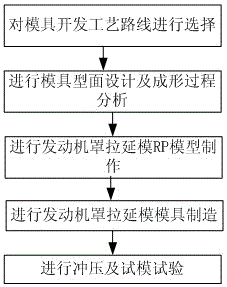

[0024] In Embodiment 1, a method for manufacturing an automobile panel mold is provided, please refer to figure 1 , the method includes:

[0025] Step 1: Select the mold development process route;

[0026] Step 2: Carry out mold surface design and forming process analysis;

[0027] Step 3: Make the RP model of the engine hood drawing die;

[0028] Step 4: Carry out engine hood drawing die manufacturing;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses an automobile covering part mold manufacturing method. The method comprises steps as follows: step 1, selecting a mold development process route; step 2, performing mold profile design and forming process analysis; step 3, manufacturing an engine cover drawing die RP model; step 4, manufacturing an engine cover drawing die mold; step 5, performing stamping and mold testing experiments. The automobile covering part mold manufacturing method has the technical effects that the manufacturing period of an automobile covering part mold is shortened, and the production cost is reduced.

Description

technical field [0001] The invention relates to the field of production and manufacturing, in particular to a method for manufacturing an automobile cover mold. Background technique [0002] The key to automobile body development lies in the design and manufacture of automobile panel molds. In the entire cycle of vehicle model design → mold design and manufacturing → mold debugging → product production, mold design and manufacturing account for about 2 / 3 of the time, becoming a key factor for the rapid launch of new models. Generally, the car body consists of hundreds of stamping parts and more than 1,000 sets of stamping dies. The development cost of the dies is about 200 million US dollars. [0003] How to quickly develop large-scale panel molds to meet the R&D and production capabilities of automobile companies has become a top priority for automobile companies. [0004] To sum up, in the process of realizing the technical solution of the invention in the embodiment of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21D37/20

CPCB21D37/20

Inventor 吴光武

Owner CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com