Adsorption material capable of removing ammonia nitrogen in solution and preparation method of adsorption material

An adsorption material and solution technology, applied in the field of water pollution control, can solve the problems of low adsorption efficiency and high price, and achieve the effects of fast adsorption speed, low price and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

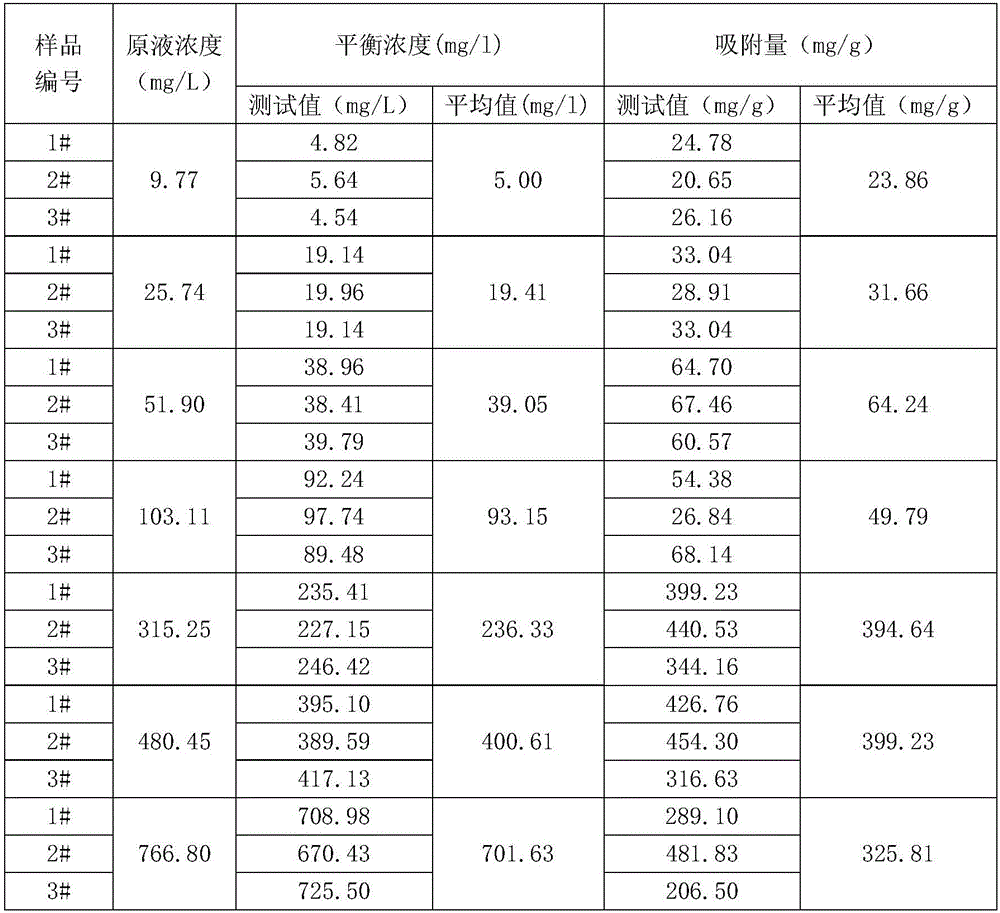

Image

Examples

Embodiment 1

[0030] An adsorption material for removing ammonia nitrogen in a solution: the raw material is cotton stalks, and the cotton stalks are anaerobically fired at 300°C for 2 hours, and the anoxic fired products are ground and passed through a 16-20 mesh sieve to collect the retentate. Then wash it with water until the pH value is constant, and dry it at 105°C for later use, so as to obtain an adsorption material for removing ammonia nitrogen in the solution.

Embodiment 2

[0032] An adsorption material for removing ammonia nitrogen in a solution: the raw material is cotton stalks, and the cotton stalks are modified by 1.0 mol / L NaOH or KOH solution. The modification method is as follows: the cotton stalks and the alkali solution are added into the alkali solution according to the solid-to-liquid ratio of 1g:2.5mL, soaked for 2 hours, and dried at 105°C.

[0033] The modified cotton stalks are anoxic fired at 300°C for 2 hours, and the anoxic fired product is ground and passed through a 16-20 mesh sieve to collect the intercepted product, then rinsed with water until the pH value is constant, and dried at 105°C Standby, must remove the adsorption material of ammonia nitrogen in the solution.

Embodiment 3

[0035] The raw material of an adsorption material for removing ammonia nitrogen in a solution is cotton stalks, and the cotton stalks are anaerobically fired at 290°C for 1 hour, and the anoxic fired products are ground and passed through a 16-20 mesh sieve to collect the retentate, and then Rinse with water until the pH value is constant, dry at 100°C for later use, and obtain an adsorption material for removing ammonia nitrogen in the solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com