A differential pressure time-sequential mixing control method for a bag filter

A bag filter and mixing control technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as increasing the cost of replacing filter bags, large filter bag load, filter bag damage, etc., and achieve increased maintenance. Period, Density Reduction, Drag Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

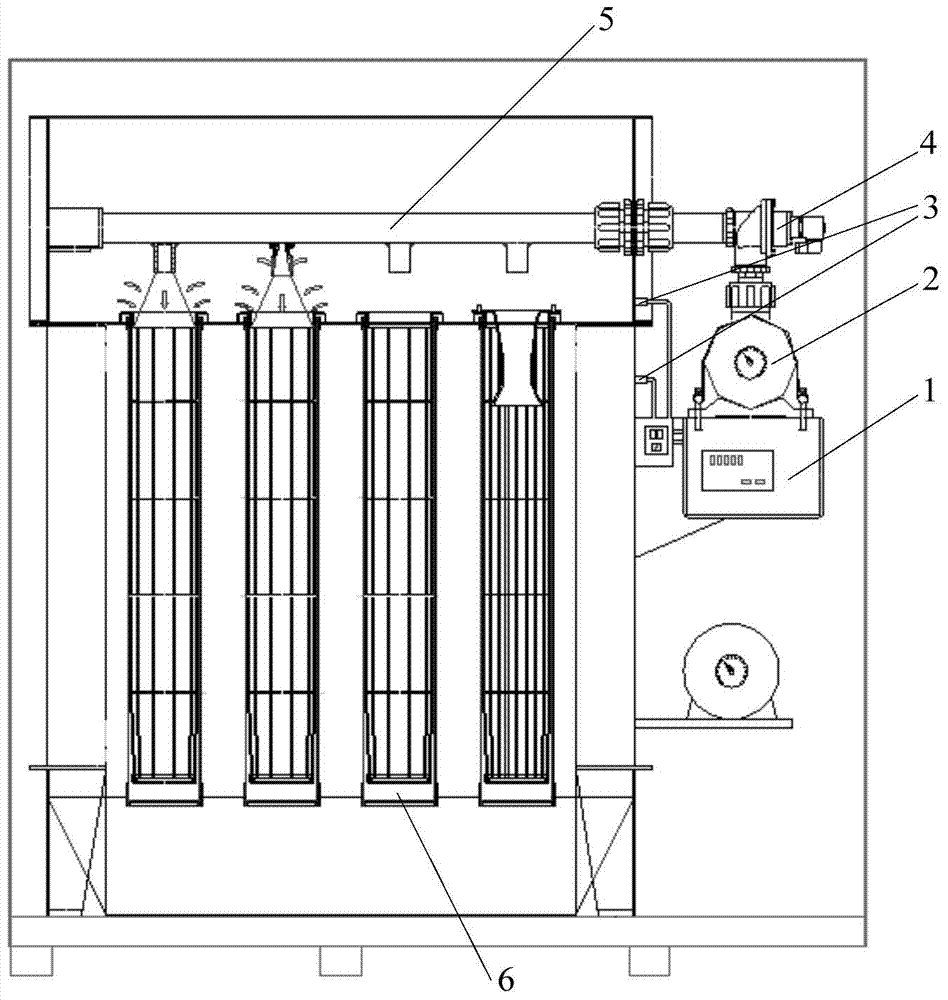

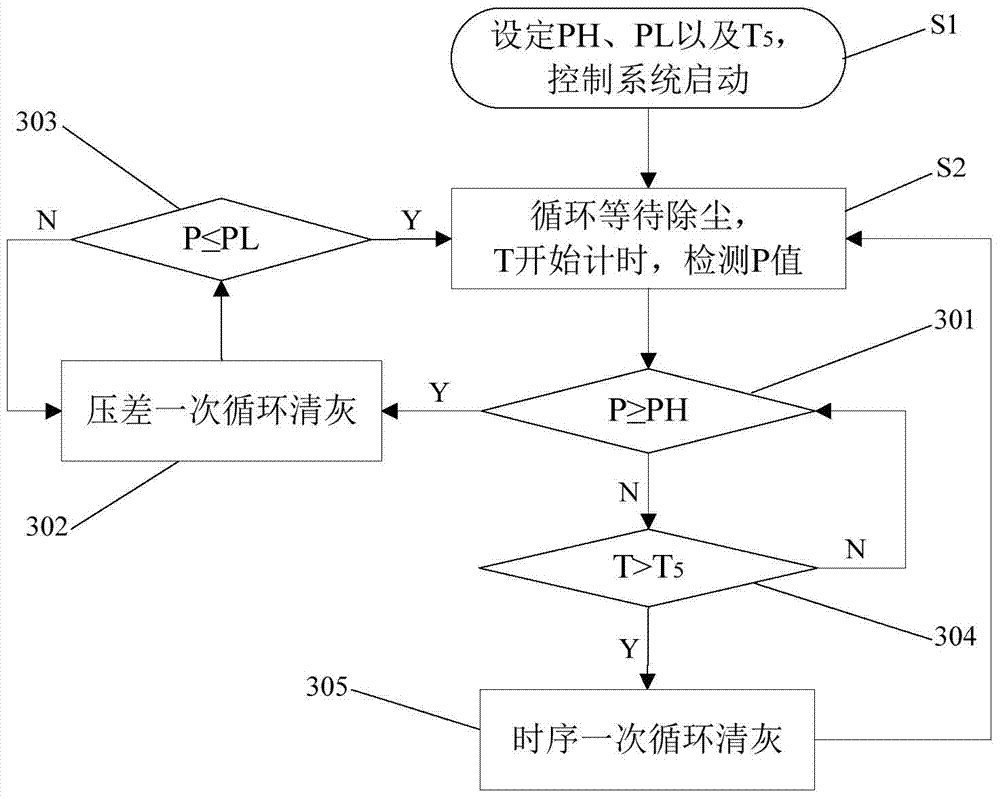

[0033] Such as figure 1 As shown, the bag filter includes a box body, a pulse controller 1, an air bag 2, a differential pressure transmitter, an electromagnetic pulse valve 4, an injection pipe 5 and a filter bag 6, and the differential pressure transmitter is located in the upper and lower boxes of the dust collector. At the differential pressure port 3 of the body, the pressure difference between the inside and outside of the filter bag 6 is detected. The pressure difference between the inside and outside increases with the increase of the amount of dust attached to the filter bag 6. The pulse controller 1 receives the transmission from the differential pressure transmitter. The pressure difference value is connected to the control electromagnetic pulse valve 4. The electromagnetic pulse valve 4 is set between the air bag 2 and the blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com