Energy-saving large casting cooling device

A technology for cooling devices and large castings, applied in the field of energy-saving cooling devices, can solve the problems of large compressed air flow, high operating costs, and large motor power of air storage tanks, and achieve the effect of saving compressed air and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

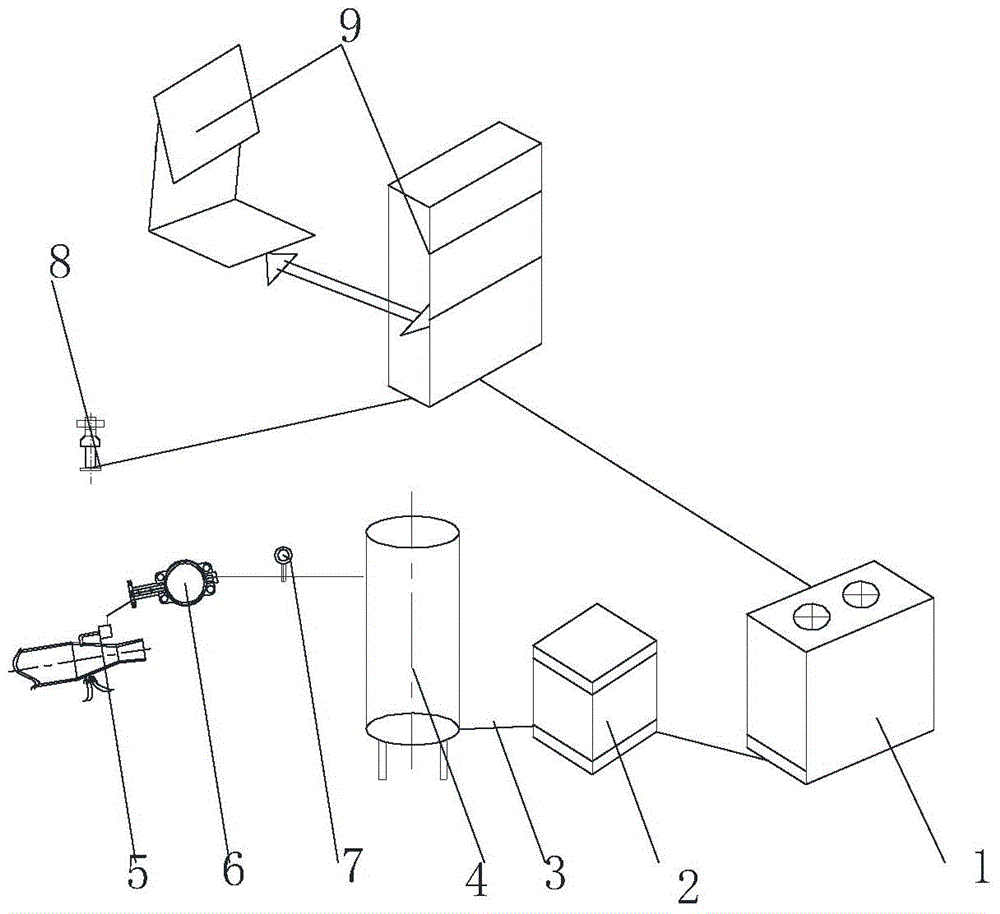

[0009] Example 1 Composition and function of an energy-saving cooling device for large castings:

[0010] An energy-saving cooling device for large castings includes an air compressor 1, a freeze dryer 2, a compressed air pipeline 3, an air storage tank 4, a venturi fan 5, a pressure regulating valve 6, a pneumatic control valve 7, a temperature transmitter 8, It is composed of an electrical control system 9, which is characterized in that a large flow of airflow is generated by a venturi fan 5 to cool large castings. The air compressor 1 is used to provide an air source. The air storage tank 4 is used to store compressed air. The inlet pipe of the venturi fan 5 is connected to the compressed air pipe 3, and the other end leads to the atmosphere. The pressure regulating valve 6 and the pneumatic control valve 7 are installed on the compressed air pipeline 3 connected to the inlet of the venturi fan 5 . The electrical control system 9 includes a PLC programmable control sy...

Embodiment 2

[0011] Example 2 Working process of an energy-saving cooling device for large castings:

[0012] The electrical control system 9 opens the pressure regulating valve 6 on the compressed air pipeline 3 according to the temperature value prompted by the test feedback of the temperature transmitter 8. When the pressure reaches the set pressure value, the pneumatic control valve 7 is opened, and the inlet of the venturi fan 5 is opened. Connect to high-pressure compressed air, and begin to generate a large amount of air flow to become a cooling medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com