Pressure control valve for negative pressure food processor

A food cooking machine and pressure control technology, applied in the field of pressure control valves, can solve problems such as loss, complex structure, and many moving parts, and achieve the effect of simple structure, small size, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

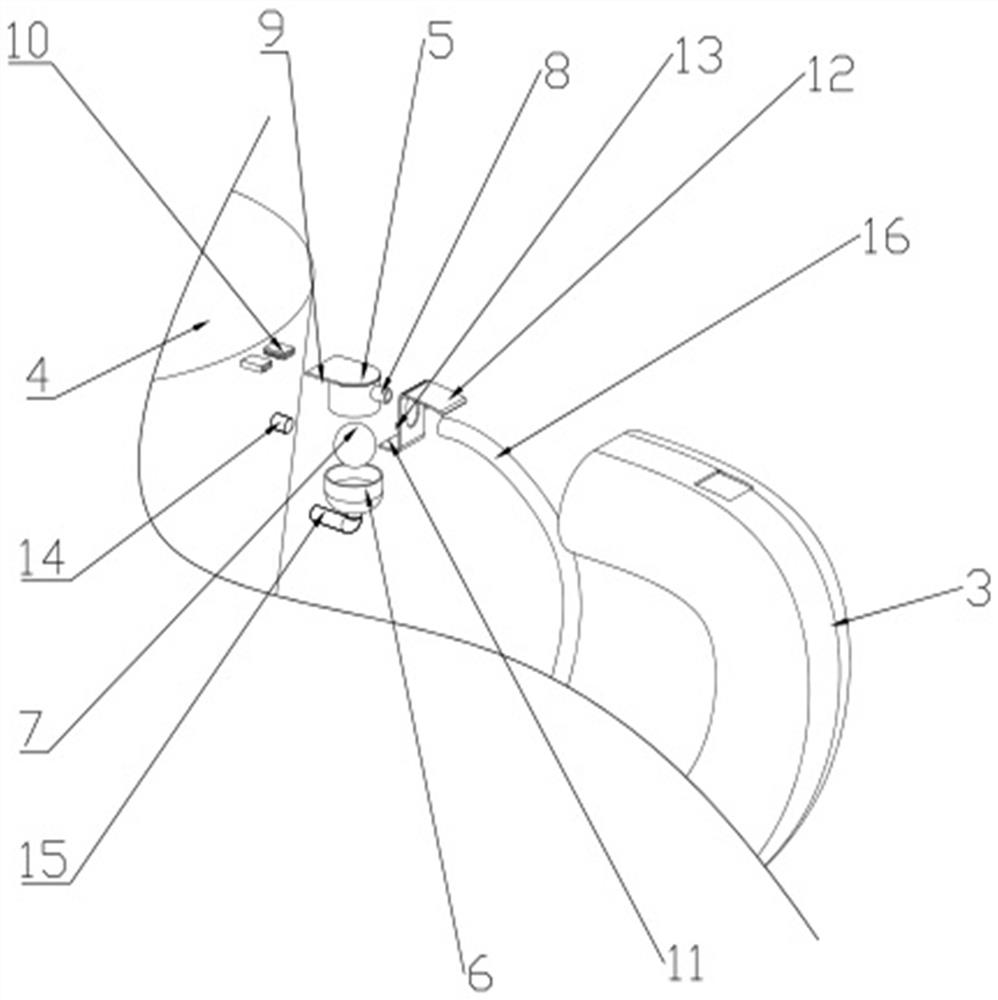

[0020] As shown in the figure, the present invention is applied to a pressure control valve on a negative pressure food cooking machine. The cooking machine is composed of a base with a drive motor and a vacuum pump inside and a cooking cup 4 installed on the base. The mouth of the cooking cup is provided with a The cup cover 1, the cup cover 1 is provided with a sealing ring 2 to seal it, and the cooking cup 4 is provided with a handle 3, and the vacuum pump is connected to the cooking cup 4 through the suction pipe 16 and the check valve. Since this kind of structure is more common in similar products, It is not the focus of the present invention. Therefore, it is neither stated here nor shown in the figures.

[0021] The check valve of the present invention includes a hard shell 5, a soft shell 6 and a valve core 7. The hard shell 5 is a short tube structure made of a small section of hard material, and the inner diameter of the short tube is slightly larger than the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com