Self-sealing refueling gun with oil vapor recovery and pressure relief function

A refueling gun and functional technology, which is applied in the field of refueling equipment, can solve problems affecting equipment safety, fuel supply pipeline burst, and fuel supply pipeline pressure load increase, to achieve the effect of ensuring equipment safety and preventing bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

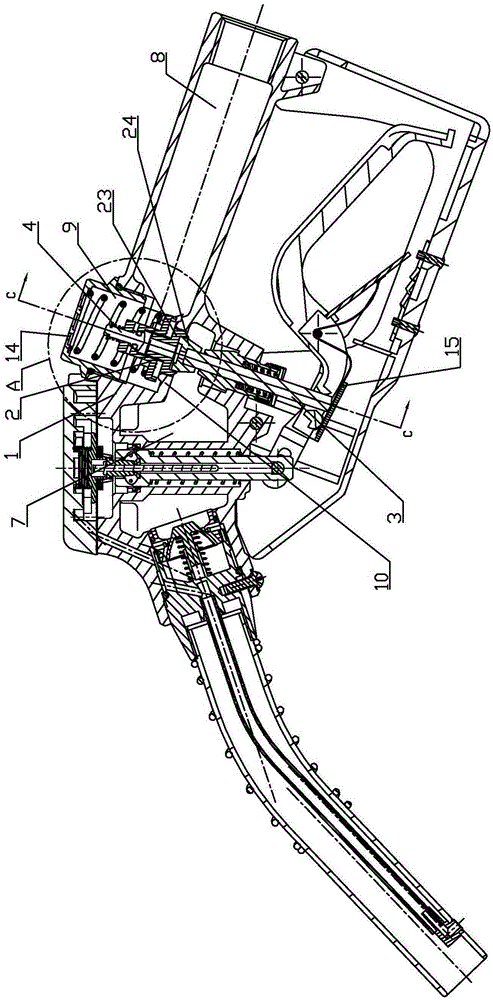

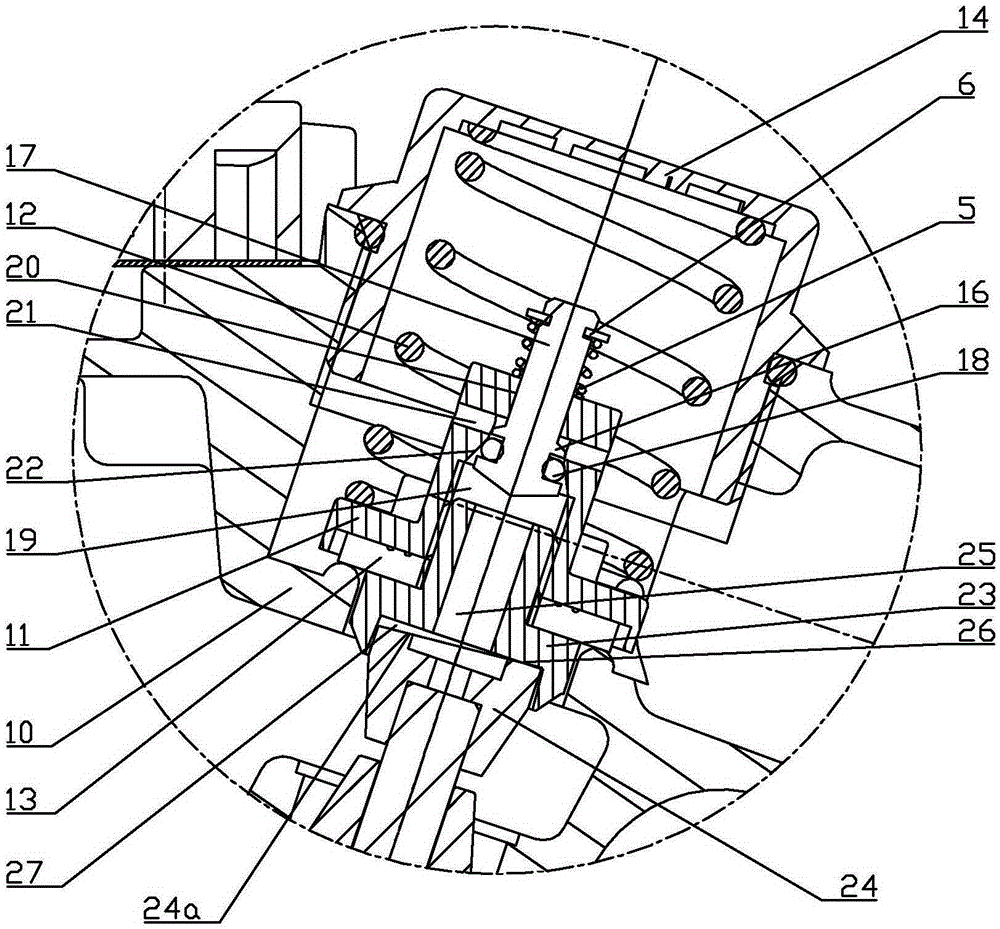

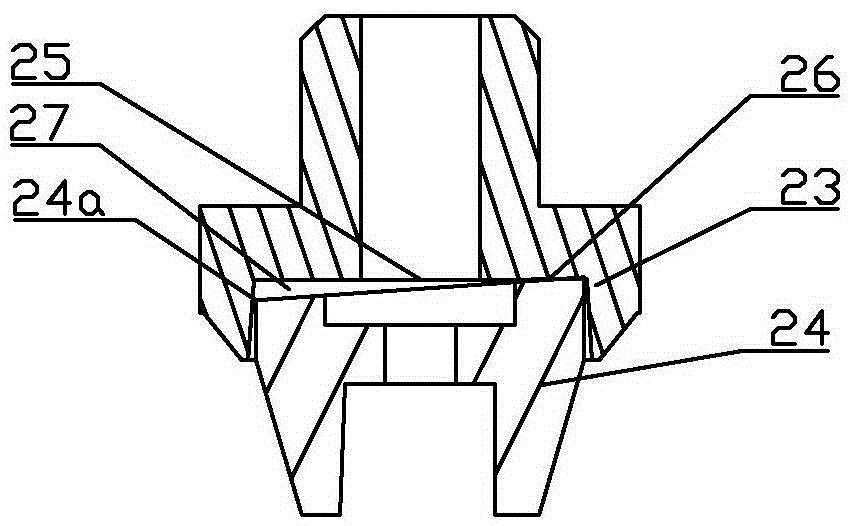

[0014] This will be further described below in conjunction with the accompanying drawings with specific embodiments, see Figure 1-Figure 3 ;

[0015] The self-styled refueling gun provided in this embodiment has the functions of oil gas recovery and pressure relief. This self-styled refueling gun also has the characteristics of methanol resistance and low temperature resistance. It includes a gun body 1 , a main valve 2 , a push rod 3 , a valve core 4 , a second compression spring 5 and a supporting part 6 . In the gun body 1 there is a refueling passage 7, an oil inlet passage 8 and a main valve chamber 9, and the oil inlet passage 8 is connected with the refueling passage 7 through the main valve chamber 9, which forms the flow of fuel on the gun body road. A valve seat 10 is formed on the gun body 1 at the adjoining position between the main valve cavity 9 and the oil filling passage 7 . The main valve 2 includes a valve disc 11, a first compression spring 12 and a gask...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com