Wing roasting material and method for preparing same

A technology for roasting wings and nutmeg, which is applied in the field of condiments, can solve the problems of loss of aroma, insufficient aroma of roasted wings, poor high temperature resistance, etc., and achieves the effects of full taste, simple preparation method and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

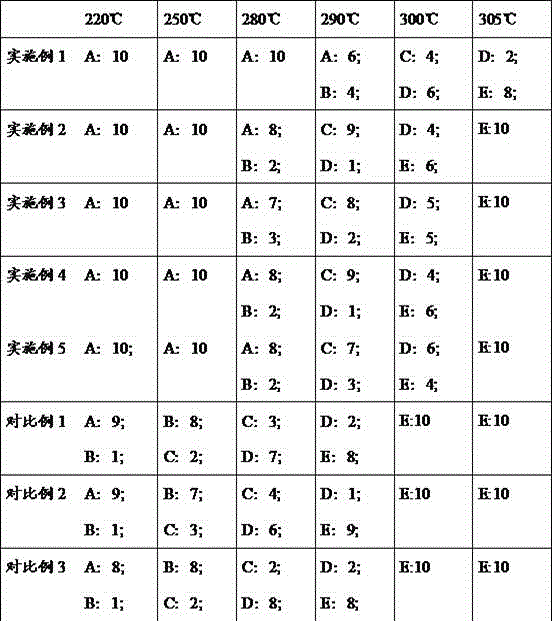

Examples

preparation example Construction

[0029] The present invention also provides a preparation method of the grilled wing material, which includes the following steps: weighing each component separately, and crushing them to a particle size of 80-120 mesh; then mixing the crushed components evenly, passing through 80 mesh Sieve, that is.

[0030] In the present invention, the preferred solution is to crush each component to a particle size of 120 mesh.

[0031] In the present invention, the preferred solution is to sterilize the grilled wing material after passing through an 80-mesh sieve.

[0032] In the present invention, the preferred solution is that the sterilization treatment is specifically: use a microwave sterilizer to perform sterilization treatment, wherein the sterilization temperature is 95-105° C., and the sterilization time is 12-16 minutes.

[0033] In the present invention, the preferred solution is to perform X-ray detection of metal foreign objects on the grilled fin stock after the sterilizati...

Embodiment 1

[0036] A kind of grilled wing material, comprising the following components in parts by weight: 5 parts of nutmeg powder, 9 parts of sand ginger powder, 11 parts of cinnamon powder, 6 parts of Angelica dahurica powder, 5 parts of tangerine peel powder, 4 parts of licorice powder, mountain pepper 3 parts of wheat flour, 6 parts of ethyl maltol, 16 parts of yeast powder, 13 parts of taste nucleotide disodium, 3 parts of table salt, 6 parts of fresh ginger powder and 0.02 part of silicon dioxide.

[0037] The roasted wing material is prepared through the following steps: weighing each component separately, and crushing to a particle size of 120 mesh; then mixing the crushed components evenly, and passing through a sieve of 80 mesh to obtain the final product.

Embodiment 2

[0039] A kind of grilled wing material, comprising the following components by weight: 6 parts of nutmeg powder, 8 parts of sand ginger powder, 11.5 parts of cinnamon powder, 4.5 parts of Angelica dahurica powder, 6 parts of tangerine peel powder, 3 parts of licorice powder, mountain pepper 4 parts of wheat flour, 5.5 parts of ethyl maltol, 17.5 parts of yeast powder, 12.5 parts of taste nucleotide disodium, 4.5 parts of salt, 4 parts of fresh ginger powder and 0.03 parts of silicon dioxide.

[0040] The roasted wing material is prepared through the following steps: weighing each component separately, and crushing to a particle size of 100 mesh; then mixing the crushed components evenly, and passing through a sieve of 80 mesh to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com