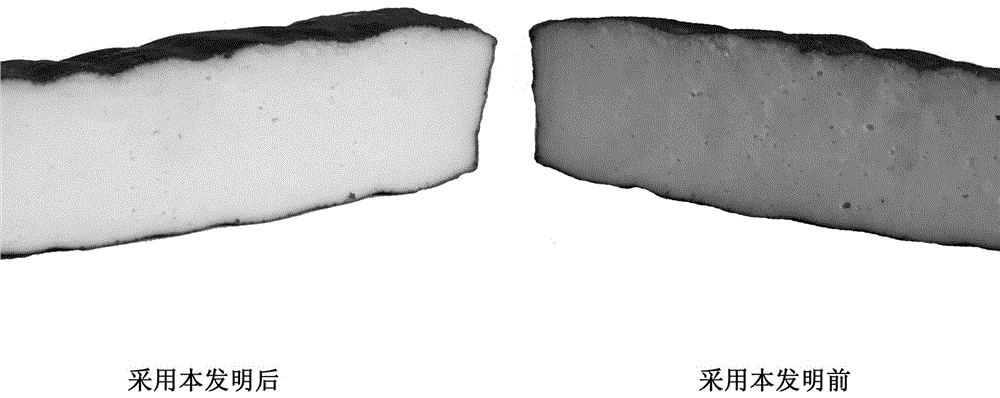

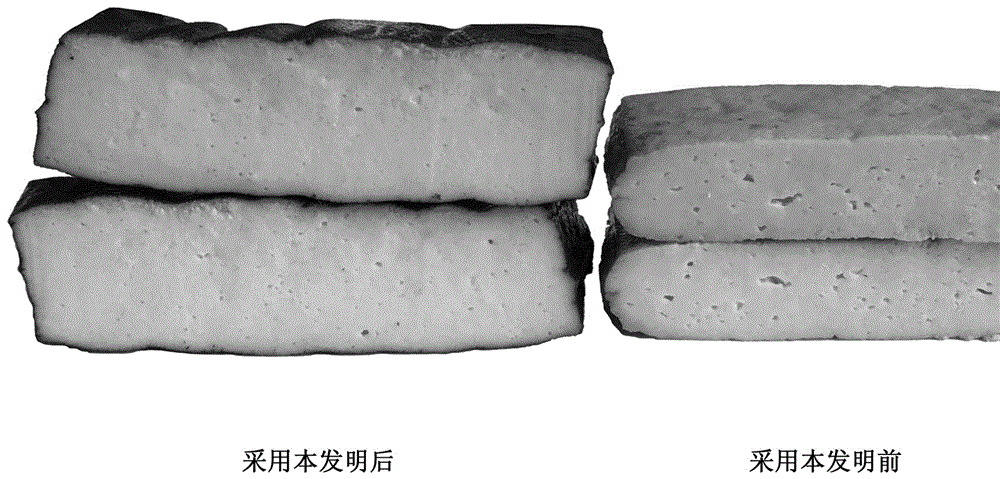

Method for enhancing texture profile of dried tofu

A technology of texture and dried tofu, which is applied in the field of food processing, can solve problems such as poor taste and rough texture of dried tofu, and achieve the effect of improving functional properties, increasing delicateness, and delicate taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for improving the texture of dried tofu, comprising the following steps:

[0028] First, the soy milk is cooked and cooled. The prepared soy milk is heated to 100°C and cooked for 15 minutes, and then the cooked soy milk is cooled to 60°C and put into the storage tank. The plate heat exchanger can be used to treat the soy milk. cool down;

[0029] Second, configure the point brine, add 0.008g of glutamine transaminase, 0.06g of starch and 0.11g of magnesium chloride to each 1kg of brine. Glutamine transaminase can react with the macromolecular protein in soybean milk to form small molecular protein, increasing the amount of dried tofu. The delicate structure, starch can make the material have a certain consistency, while maintaining a certain fluidity;

[0030] The third step is to squat and squat, add 45g of prepared brine to every kilogram of 60°C soybean milk, stir well, and squat for 20 minutes. At a temperature of 60°C, the activity of transglutaminase is...

Embodiment 2

[0036] A method for improving the texture of dried tofu, comprising the following steps:

[0037] First, soymilk is cooked and cooled, the prepared soymilk is heated to 100°C and cooked for 15 minutes, then the cooked soymilk is cooled to 70°C and put into the milk storage tank;

[0038] Second, configure point brine, add 0.012g of transglutaminase, 0.08g of starch and 0.13g of magnesium chloride to each 1kg of brine. The delicate structure, starch can make the material have a certain consistency, while maintaining a certain fluidity;

[0039] The third step is to squat and squat, add 35g of ready-made brine to every kilogram of 70°C soybean milk, stir well, and squat for 25 minutes. At a temperature of 70°C, the activity of transglutaminase is also relatively high , to fully react with the macromolecular protein in soymilk to generate small molecular protein until the tofu with delicate taste is obtained;

[0040] Fourth, pressing, crushing the tofu, and pressing into frame...

Embodiment 3

[0045] A method for improving the texture of dried tofu, comprising the following steps:

[0046] First, soymilk is cooked and cooled, the prepared soymilk is heated to 100°C and cooked for 15 minutes, then the cooked soymilk is cooled to 60°C and put into the milk storage tank;

[0047] Second, configure the point brine, add 0.01g of glutamine transaminase, 0.07g of starch and 0.12g of magnesium chloride to each 1kg of brine. Glutamine transaminase can react with the macromolecular protein in soybean milk to form small molecular protein, increasing the amount of dried tofu. The delicate structure, starch can make the material have a certain consistency, while maintaining a certain fluidity;

[0048] The third step is to squat and squat, add 40g of prepared brine to every kilogram of 60°C soybean milk, stir well, and squat for 30 minutes. At a temperature of 60°C, the activity of transglutaminase is high. The macromolecular protein in soy milk fully reacts to form small molec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com