Torque modulation for internal combustion engine

一种内燃发动机、发动机的技术,应用在发动机元件、发动机控制、机器/发动机等方向,能够解决慢量级、不完全燃烧等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

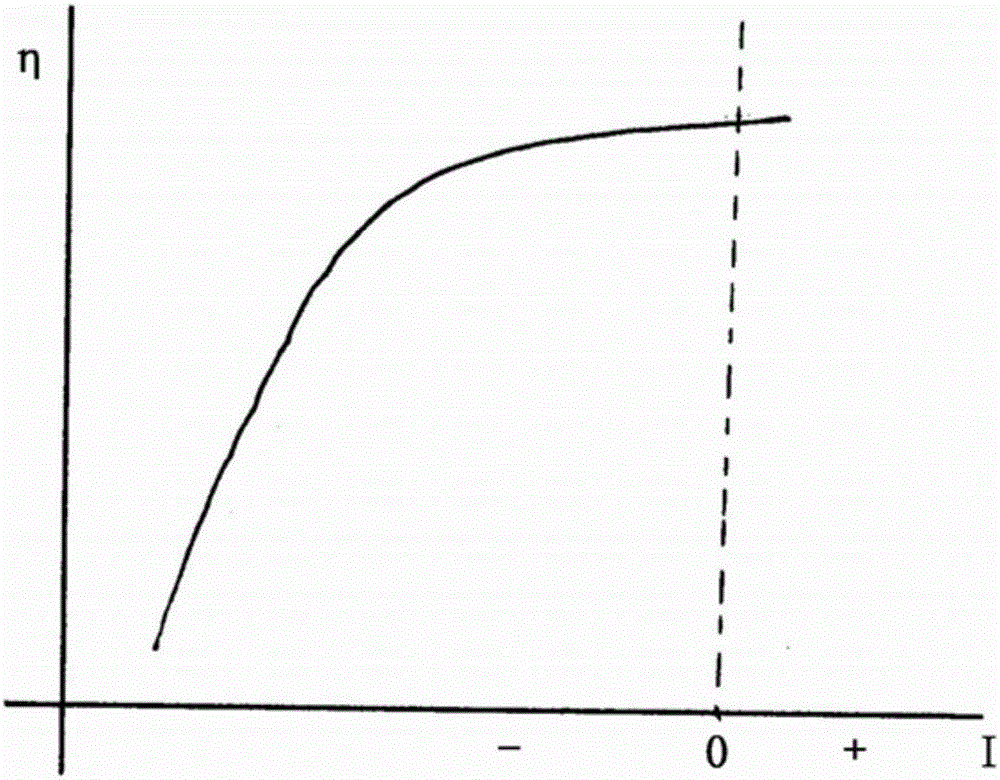

Image

Examples

Embodiment Construction

[0029] Referring to the drawings, an internal combustion engine 10 has a cylinder 11 in which a piston 12 reciprocates. A combustion chamber 13 is defined above the piston and houses a poppet valve 14 which opens to admit air from an intake port 15 . The intake port is fed from an intake manifold 16 at the mouth of which a throttle valve 17 is provided.

[0030] The poppet valve 14 is closed by a spring (not shown) and opened by the action of a rotatable cam 18, usually provided by the lobe of the camshaft. A push rod 19 is arranged between the cam 18 and the valve 14 .

[0031] figure 1 The general arrangement of is very common, and some other components, such as corresponding poppet exhaust valves, are not shown for ease of illustration. Typically, the push rod 19 is solid, and the push rod 19 may be passive in character.

[0032] However, figure 1 The pushrod is active and is characterized by a hydraulic chamber 20 whose volume is determined by the opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com