Image sensor and forming method thereof

An image sensor and pixel area technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of poor performance of image sensors, affect image quality, and generate dark current, so as to reduce the probability of diffusion and dark current , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Existing silicon-on-insulator (SOI) CMOS image sensors have problems of large dark current and poor performance.

[0036] Now in combination with a CMOS image sensor, the reasons for the large dark current and poor performance of the silicon-on-insulator (SOI) CMOS image sensor are analyzed:

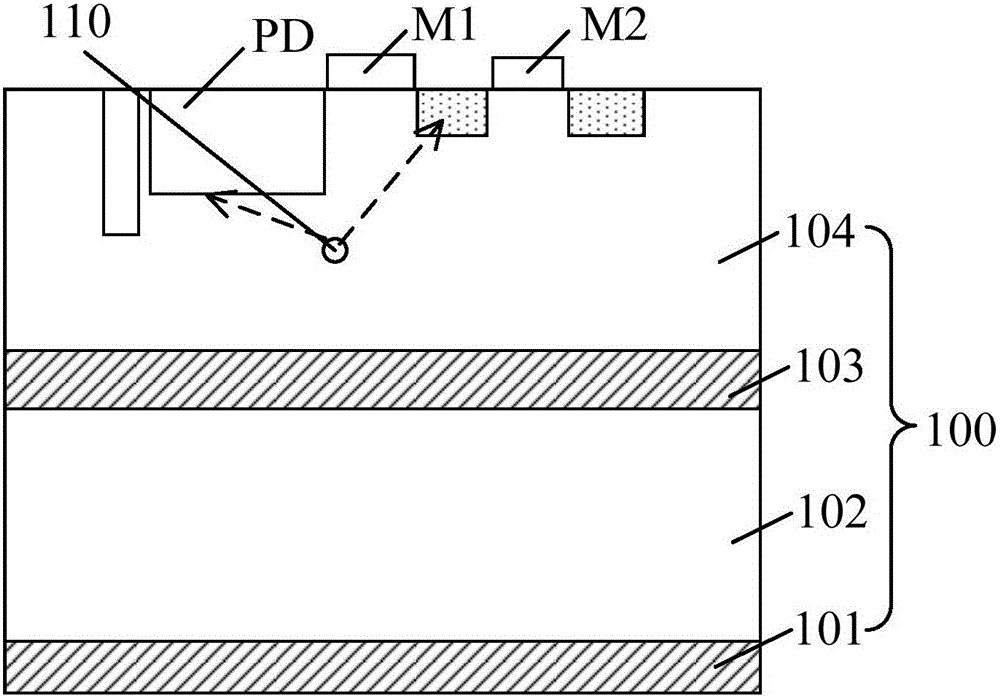

[0037] figure 1 It is a structural schematic diagram of a silicon-on-insulator (SOI) CMOS image sensor. The CMOS image sensor includes:

[0038] SOI substrate 100, described SOI substrate 100 comprises: wafer back absorption layer 101; The underlying substrate 102 that is positioned at the back surface absorption layer 101; The buried oxide layer 103 that is positioned at the bottom substrate 102 surface; The top substrate 104.

[0039] In the pixel area located in the top substrate 104, the pixel area includes a semiconductor device unit, and the semiconductor device unit includes a photodiode PD, a transfer transistor M1 and a reset transistor M2.

[0040] During the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com