Radiator for laser display and preparation method of radiator

A heat dissipation device and laser display technology, which is applied in coatings, electrical components, circuits, etc., can solve the problems of the size of the heat sink and the heat dissipation performance, the small specific surface area of the graphene film, and the poor adhesion and flatness of the film. Achieve enhanced thermal conductivity, reduced size, and reduced air defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

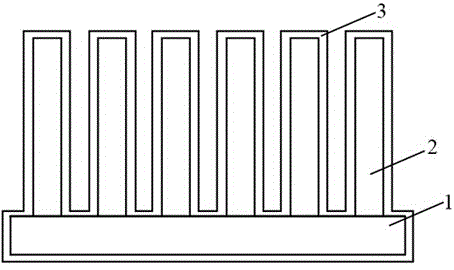

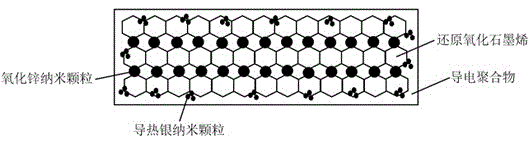

[0033] A heat dissipation device for laser display and its preparation method, the structure of heat conduction substrate 1 and heat dissipation fins 2 is as follows figure 1 As shown, first use detergent, acetone solution, deionized water and isopropanol solution to thoroughly clean the thermally conductive substrate 1 and heat dissipation fins 2, and dry them after cleaning; spray on the thermally conductive substrate 1 and heat dissipation fins 2 The main raw material solution, the spraying rate is 5μl / s, and the spraying time is 60s. After spraying, a graphene oxide / zinc oxide composite film is formed; when the main raw material solution is not completely dry, continue spraying on the graphene oxide / zinc oxide composite film Filling material solution, the spraying rate is 2μl / s, and the spraying time is 15s. After spraying, the defects and gaps of the graphene oxide / zinc oxide composite film are filled to form a flat composite coating; the formed composite coating is subjec...

Embodiment 2

[0036] A heat dissipation device for laser display and its preparation method, the structure of heat conduction substrate 1 and heat dissipation fins 2 is as follows figure 1 As shown, first use detergent, acetone solution, deionized water and isopropanol solution to thoroughly clean the thermally conductive substrate 1 and heat dissipation fins 2, and dry them after cleaning; spray on the thermally conductive substrate 1 and heat dissipation fins 2 The main raw material solution, the spraying rate is 5μl / s, and the spraying time is 60s. After spraying, a graphene oxide / zinc oxide composite film is formed; when the main raw material solution is not completely dry, continue spraying on the graphene oxide / zinc oxide composite film Filling material solution, the spraying rate is 2μl / s, and the spraying time is 15s. After spraying, the defects and gaps of the graphene oxide / zinc oxide composite film are filled to form a flat composite coating; the formed composite coating is subjec...

Embodiment 3

[0039] A heat dissipation device for laser display and its preparation method, the structure of heat conduction substrate 1 and heat dissipation fins 2 is as follows figure 1 As shown, first use detergent, acetone solution, deionized water and isopropanol solution to thoroughly clean the thermally conductive substrate 1 and heat dissipation fins 2, and dry them after cleaning; spray on the thermally conductive substrate 1 and heat dissipation fins 2 The main raw material solution, the spraying rate is 5μl / s, and the spraying time is 60s. After spraying, a graphene oxide / zinc oxide composite film is formed; when the main raw material solution is not completely dry, continue spraying on the graphene oxide / zinc oxide composite film Filling material solution, the spraying rate is 2μl / s, and the spraying time is 15s. After spraying, the defects and gaps of the graphene oxide / zinc oxide composite film are filled to form a flat composite coating; the formed composite coating is subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com