A multifunctional biomimetic microstructure surface testing device

A surface testing and microstructure technology, used in adhesion and film thickness equipment, and in the field of measuring material friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

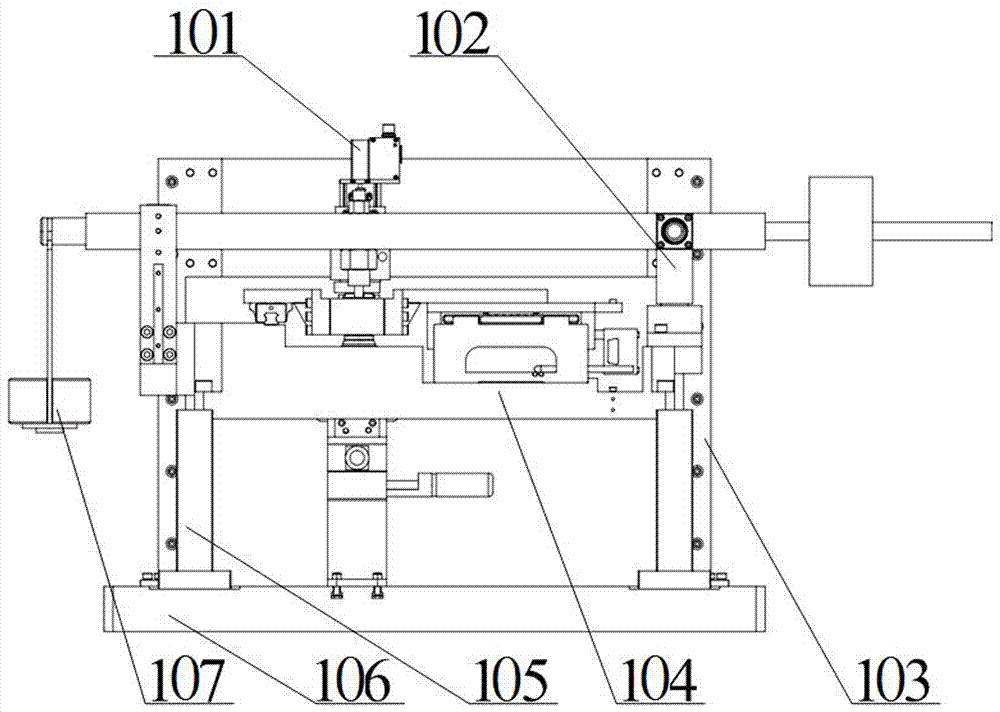

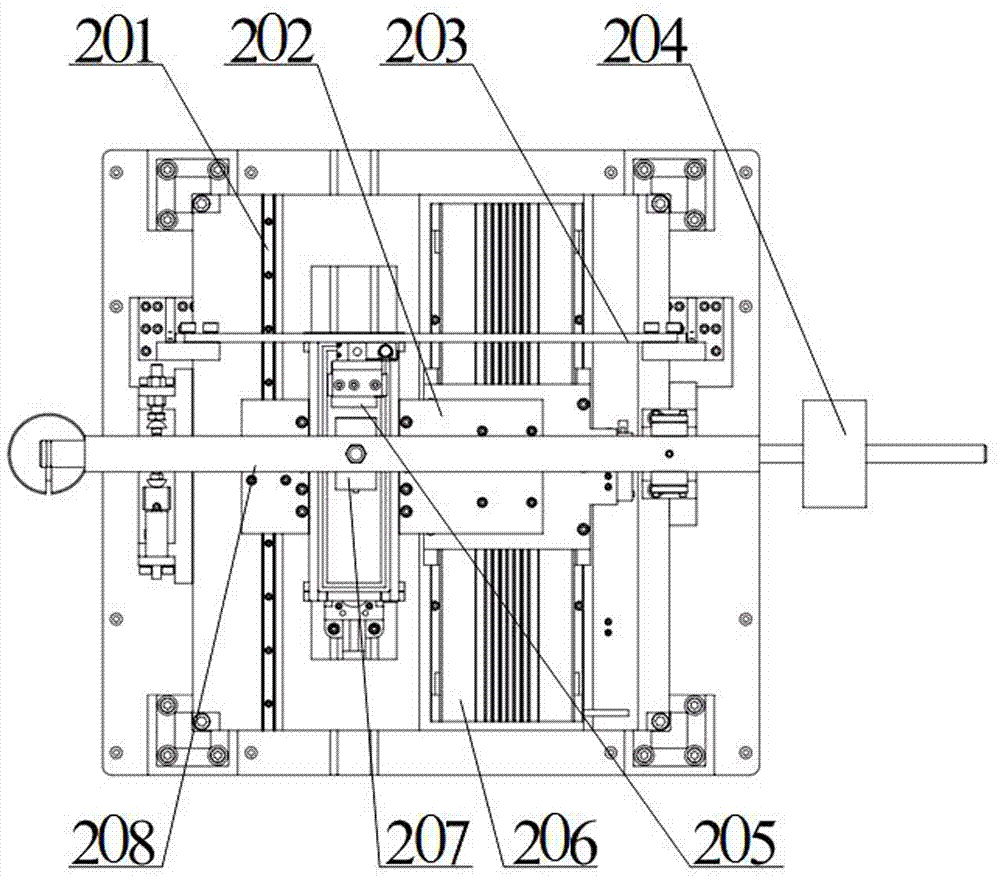

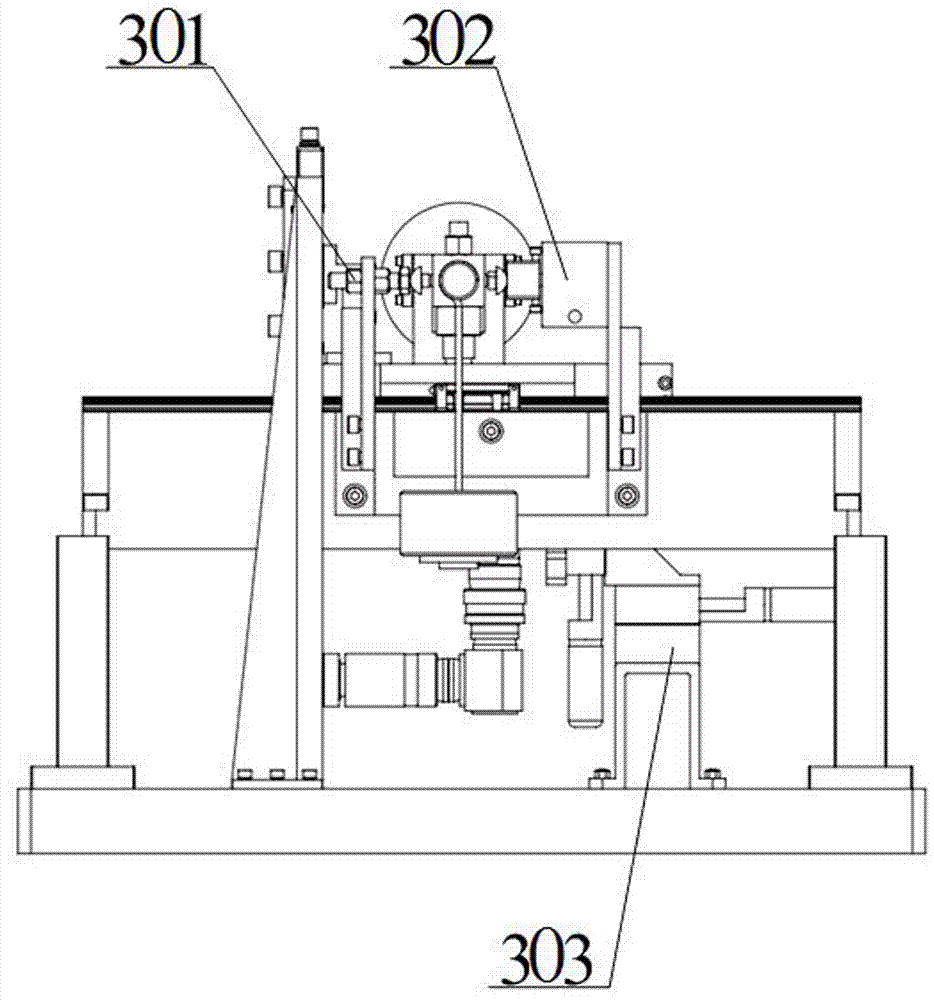

[0015] see Figure 1-4 , a multifunctional bionic microstructure surface testing device, comprising an adhesion test drive 101, a friction test rod shaft 102, a friction test prototype bottom support plate 106, a friction test rod 208, a friction test sensor preloading device 301, Thin film detection device 303 and microscope device, described friction test prototype bottom support plate 106 is equipped with beam support rod 103 and friction test prototype middle layer support plate support 105, and described cross beam support rod 103 is positioned at friction test prototype middle layer support plate support 105 On the rear side, the middle support plate 104 of the friction test prototype is installed on the middle support plate support 105 of the friction test prototype, and the friction test rod rotating shaft 102 is installed on the middle sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com