Automatic glue coating and spinning device for semiconductor silicon wafer and key structure of automatic glue coating and spinning device

A technology for semiconductors and silicon wafers, which is applied to the field of automatic gluing and gluing devices for semiconductor silicon wafers, can solve problems such as inability to meet the requirements of use and small motor torque, and achieve the effects of simple structure, prevention of air leakage and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0040] The following example is an embodiment of the automatic coating device of a semiconductor wafer according to the present application.

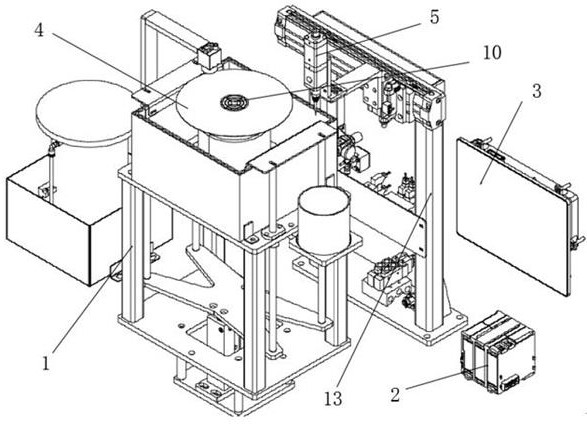

[0041] See Figure 1-12 As shown, a semiconductor silicon wafer automatic coating rubber device includes a body 1, a mounting frame 13, a PLC2, a manual interface 3, a rubber assembly 4, a flash assembly 5, and a high speed vacuum assembly 10; wherein the body One side is fixedly connected to the mounting frame 13, the top side of the mounting frame 13 is fixedly connected to the drip assembly 5, and the bottom side of the drip assembly 5 is provided with a rubber assembly 4 placed in the body 1, the spin glue. A high speed vacuum assembly 10 is provided in the assembly 4, and the human machine interface 3 and PLC2 provided on one side of the body 1;

[0042] The rubber assembly 4 includes a lifting cylinder 406, a lifting plate 405, a silicon wafer 401, a gelatin thickness sensor 402, a guide post 403, and a connecting frame 404, and the li...

specific Embodiment 2

[0054] The following example is an embodiment of a gelatin assembly according to a semiconductor wafer automatic coating rubber device, which can be performed separately, and can be automatically applied as a semiconductor wafer disclosed in the specific embodiment. Key structure of glue rubber device.

[0055] A gelatin assembly of a semiconductor wafer automatic coating rubber rubber device, including: lifting cylinder 406, a lift plate 405, a silicon wafer 401, a glue thickness sensor 402, a guide post 403, and a connecting frame 404, the lifting cylinder 406 fixed Connecting on the bottom side of the body 1, the lift cylinder 406 is fixedly coupled with a lifting plate 405, and the top side of the lifting plate 405 is fixedly coupled with a guide post 403, and the tip of the guide post 403 is fixedly connected to the lifting cover 15, said The lifting cover 15 outer wall slid on the cover 16, the shroud 16 is provided with a base 14 fixed to the top side of the body 1, and the...

specific Embodiment 3

[0057] The following example is an example of a drip assembly of a semiconductor wafer automatic coating glue apparatus, which can be carried out alone and can be automatically applied as a semiconductor wafer disclosed in the specific embodiment. Key structure of glue rubber device.

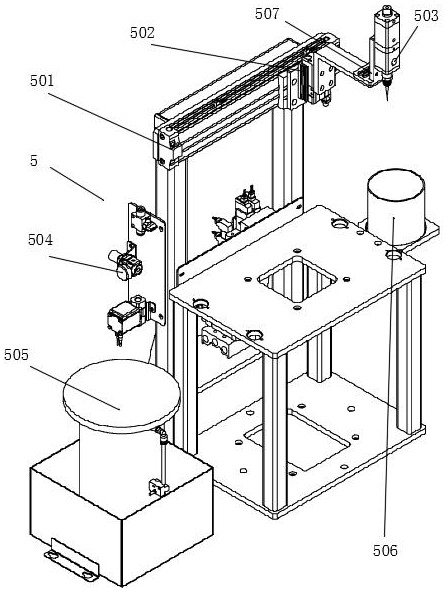

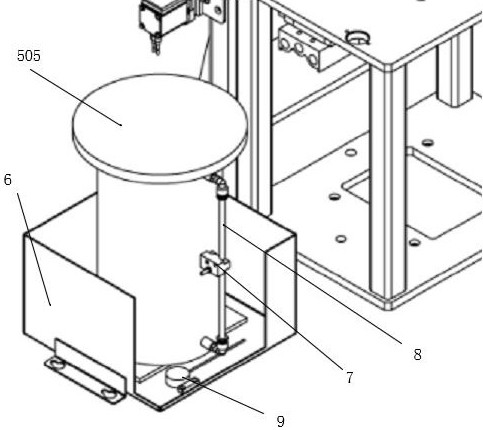

[0058] A semiconductor silicon wafer automatic coating glue apparatus of a glue device, including: horizontal cylinder 501, vertical cylinder 502, drip valve 503, pressure regulator valve 504, colloidal pressure can 505, a raised container 506, and a fixing frame 507, The horizontal cylinder 501 is fixedly coupled to the top side surface of the mounting frame 13, the horizontal cylinder 501 output, and the vertical cylinder 502 is fixed, and the vertical cylinder 502 is fixedly connected to the fixing frame 507, the fixing frame 507 side. The surface is fixedly connected with a drip valve 503, and the drip valve 503 is provided with a regulator valve 504 on the communication gas path of the colloida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com