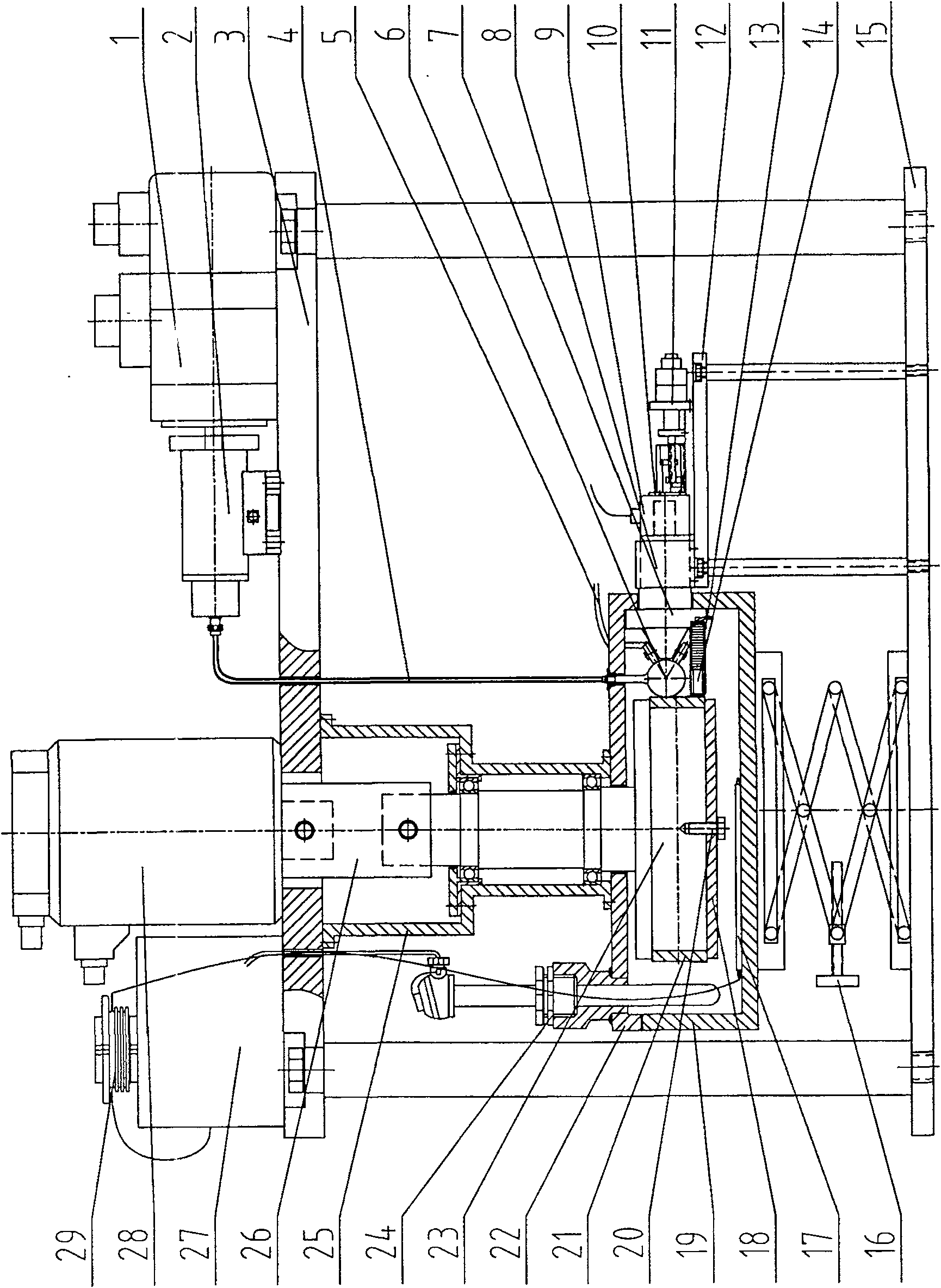

Heavy pressure micro-gap lubrication test machine

A lubricating testing machine and micro-gap technology, applied in the field of testing machines, can solve the problems of material lubricating bearing capacity and rheological properties that have not yet been studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] As shown in the accompanying drawings, the high-pressure micro-gap lubrication testing machine is composed of a support platform, a lifting table 16, a mechanical system, a loading system, a film thickness measurement system, a friction measurement system and a temperature control system. The support platform is connected by the base 15, the support platform 3, the support 12 and the support rods therebetween; Above; the material in the mechanical system is Si 3 N 4 The ceramic ball 6, the mechanical system includes a fuel tank system and a spindle system, the fuel tank system is composed of two parts, the fuel tank 19 and the fuel tank cover 22, the fuel tank 19 is fixed on the lifting table 16, and the fuel tank cover 22 is covered on the fuel tank 19, and there is a plane between them. Sealant, to ensure better sealing when there is a slight movement between the fuel tank cover 22 and the fuel tank 19; the main shaft system is composed of a servo motor 28, a shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com