Diagonal flow pump

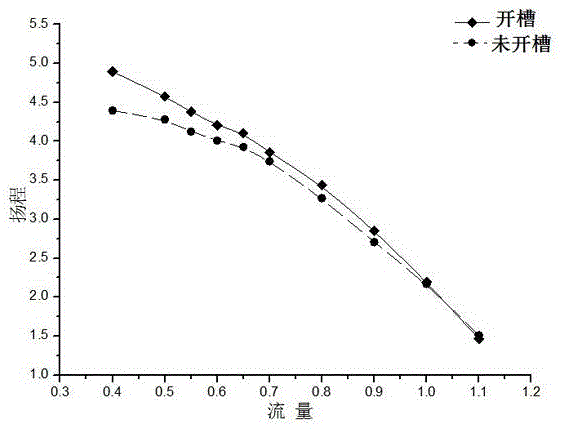

A technology of oblique flow pump and pump shaft, which is applied in the direction of pumps, pump components, and parts of pumping devices for elastic fluids, etc. Large, increase the flow instability of the oblique flow pump, etc., to achieve the effect of reducing the back pressure gradient, reducing the peripheral velocity component of the incoming flow, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

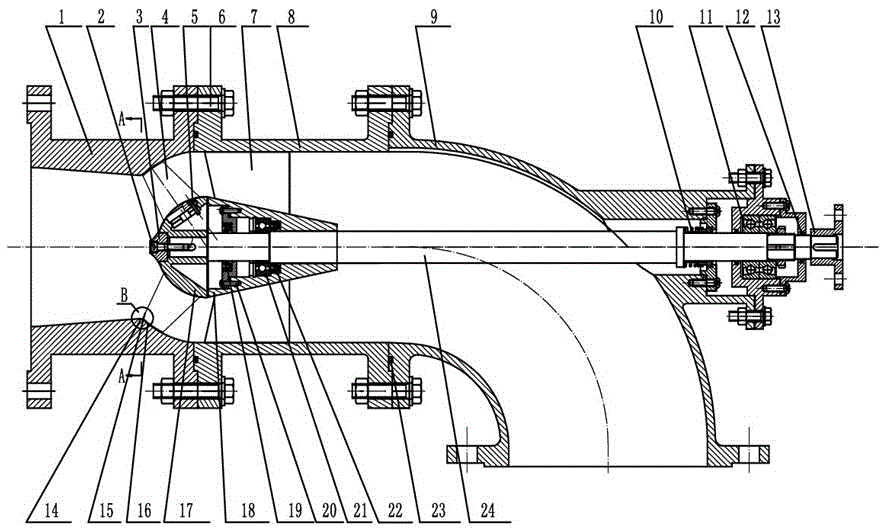

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

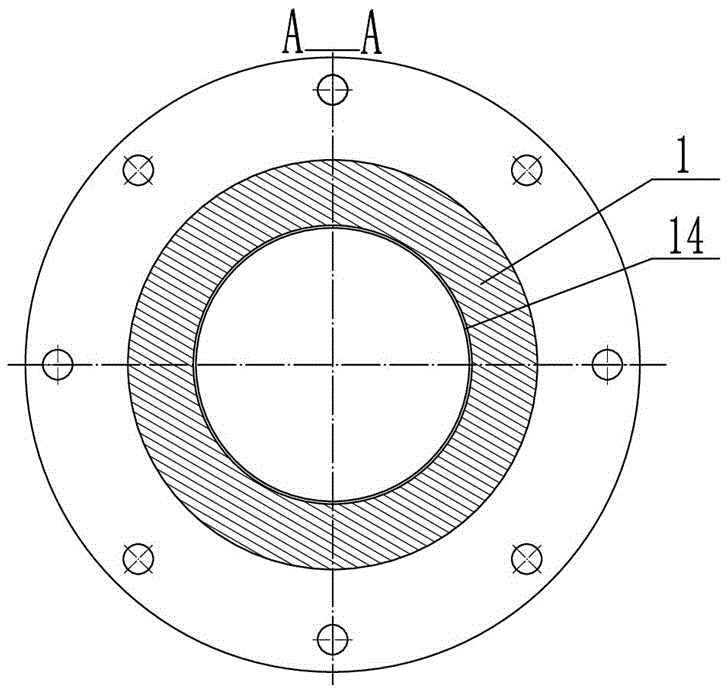

[0022] Depend on figure 1 figure 2 with image 3 It can be seen that the inclined flow pump is composed of an inlet section 1, a hexagon socket head screw 2, a water guide cone 3, a blade 4, a cylindrical head screw 5, a bolt 6, a guide vane 7, a cylindrical outer cylinder 8, and an elbow section 9 , mechanical seal 10, angular contact ball bearing 11, washer oil seal 12, coupling 13, annular groove 14, runner hub 17, guide vane body 18, bearing left oil seal 19, hexagon socket flat head screw 20, deep groove ball Bearing 21, bearing right oil seal 22; O-shaped sealing ring 23, pump shaft 24. The inlet section 1 is connected and fixed with the cylindrical outer cylinder 8 through the bolt 6, and the inlet section 1 and the cylindrical outer cylinder 8 are positioned and ensured concentricity through concave-convex fitting; the cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com