A kind of anti-rutting pavement structure and laying method thereof

A pavement structure, anti-rutting technology, applied in the direction of roads, roads, condensed pavement paved on site, etc., can solve the problems of inability to effectively resist rutting, the overall coordinated deformation ability and the weak resistance to cracks, etc., to improve the overall deformation. Coordination ability, short construction and maintenance period, good resistance to cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

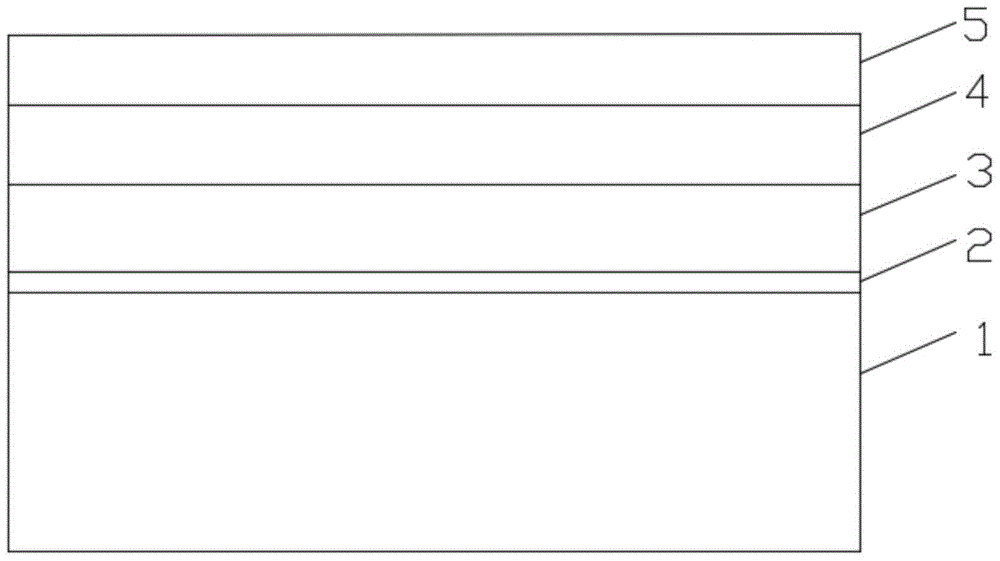

[0048] like figure 1 The rutting-resistant pavement structure of the poured asphalt mixture shown, from bottom to top, the semi-rigid base, the SBS emulsified asphalt bonding layer, the type II latex cement mortar poured asphalt concrete layer, and the I type latex cement mortar poured in Type asphalt concrete layer, high viscosity modified asphalt SMA-13 concrete layer.

[0049] Among them, the amount of semi-rigid base and SBS emulsified asphalt bonding layer is 0.6kg / m 2 , The thickness of the type II latex cement mortar poured asphalt concrete layer is 8cm, the thickness of the I type latex cement mortar poured asphalt concrete layer is 5cm, and the thickness of the high viscosity modified asphalt SMA-13 concrete layer is 4cm.

[0050] The type II latex cement mortar poured asphalt concrete material layer is composed of large-pore open-graded asphalt mixture and latex cement mortar in a mass ratio of 6:1; wherein, the large-pore open-graded asphalt mixture is composed...

Embodiment 2

[0058] In this comparative example, the pavement structure is sequentially provided with a semi-rigid base layer, an SBS emulsified asphalt bonding layer, a lower layer, a middle surface layer, and a surface layer from bottom to top.

[0059] Among them, the amount of semi-rigid base and SBS emulsified asphalt bonding layer is 0.6kg / m 2 , The thickness of the lower layer is 8cm, the thickness of the middle layer is 5cm, and the thickness of the surface layer is 4cm.

[0060] According to the relevant regulations on the minimum compaction degree and suitable thickness of the asphalt mixture structural layer in Table 4.1.3 of "Code for Design of Highway Asphalt Pavement" (JTGD50-2006), the maximum nominal particle size of the type II latex cement mortar poured asphalt concrete It is 19mm, corresponding to a suitable thickness of 60-80mm, so it can only be used in the lower layer, and cannot be used in the upper layer of 40mm and the middle layer of 50mm, otherwise the structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com