Oxygenation decoking agent

A technology of decoking agent and copper oxide, which is applied in the direction of fuel additives, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems that the calorific value of fuel cannot be fully exerted, reduce the service life of combustion equipment, and the combustion equipment is highly corrosive, etc., to achieve Reduce poisoning and spillage, save fuel, and reduce the effect of air supply and induced air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

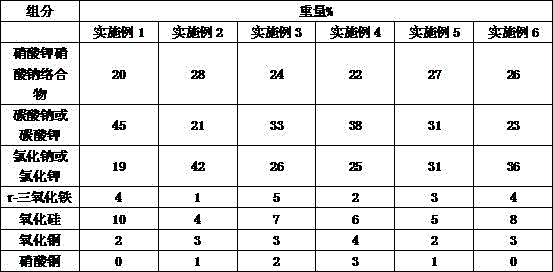

Embodiment 1-6

[0013] First dry each component to make the water content less than 5%, and then pulverize, the particle diameter is required to be 0.05-0.3mm, and then carry out the batching according to the proportions of the following examples, stir after the batching to make it fully mixed, and then Screening is carried out to obtain a solid powder additive with a light red particle diameter of 0.05-0.3 mm.

[0014]

[0015] The invention is an additive used in coal-fired furnaces and large-scale boilers in power plants. It produces special skiing reactions at high temperatures and produces significant effects of energy saving and emission reduction. It is non-toxic, non-corrosive, non-secondary pollution, explosion-proof, safe, and pH value of 10 or more.

[0016] 1. Energy-saving effect: the ignition point of the fuel is promoted earlier, the combustion is more complete, the combustible matter of ash residue, carbon fly ash is significantly reduced, and the amount of oxygen in the hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com