PVC flame-retardant fire-protection threading pipe

A threading pipe and fire-fighting technology, which is applied in the field of PVC flame-retardant fire-fighting threading pipes, can solve the problems of non-flammability of flame-retardant PVC threading pipes, affecting performance, general flame-retardant effect, etc., and achieves convenient and fast installation and use, long service life, Inexpensive effect

Inactive Publication Date: 2016-06-15

SHANGHAI SHANGSU HLDG GRP

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, many users basically use ordinary flame-retardant PVC threading pipes in their buildings to protect all strong and weak current lines such as network lines, telephone lines, and alarm lines. However, most flame-retardant PVC threading pipes are not flame-retardant or even combustion-supporting. , once an electrical line fire occurs, the "flame retardant line pipe" will be ignited and release a large amount of toxic gas and smoke, which will cause a very unfavorable situation for personnel evacuation and rescue, and will cause a greater fire safety hazard

[0003] For the existing flame-retardant PVC threading pipes, the Ministry of Public Security's standard requires higher combustion performance for such products, while the requirements of the Ministry of Construction's standard are correspondingly much lower. Except for the oxygen index requirement of 32, it does not reflect fire hazards. Requirements for the smoke density level of important indicators of building materials that affect people's escape under certain conditions

The parallelism of these three standards with different requirements is the main reason for the uneven quality of flame-retardant PVC threading pipe products on the market.

[0004] Therefore, the flame-retardant PVC threading pipes on the market now have different quality on the one hand, and on the other hand, even if the flame-retardant effect is achieved through the selection of additives, there are often disadvantages such as overweight material, general flame-retardant effect, and weakened insulation. result

While this affects performance, it cannot be widely and long-term used in various fields.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

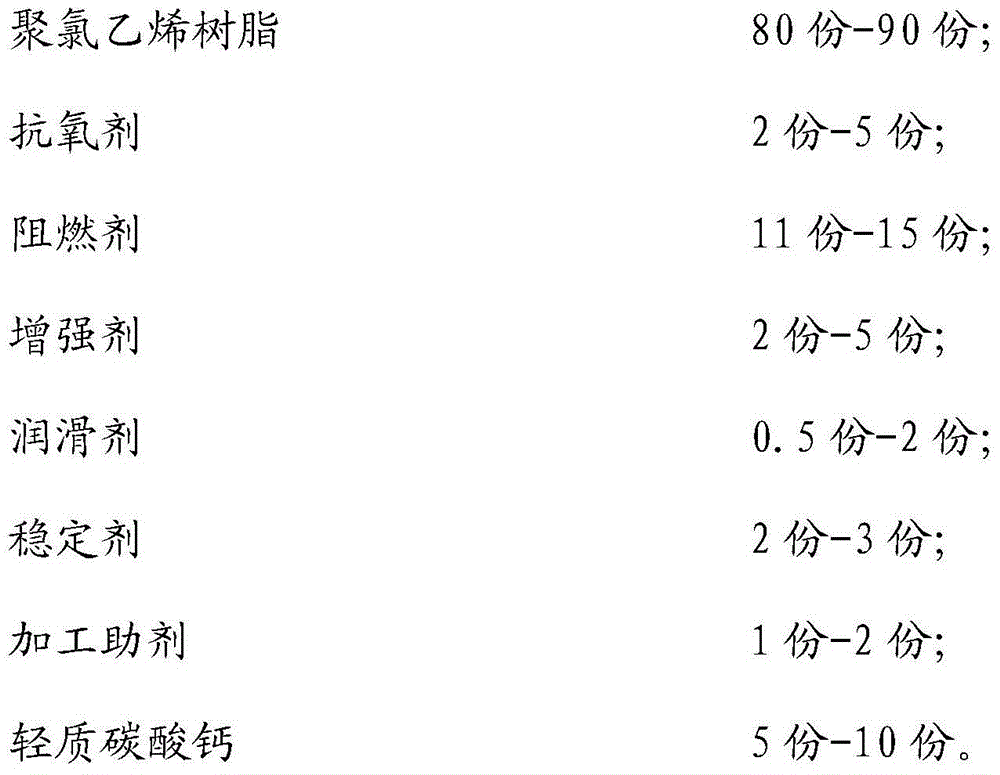

[0035] Embodiment 1, PVC flame-retardant fire-fighting threading pipe 1#

[0036]

[0037]

Embodiment 2

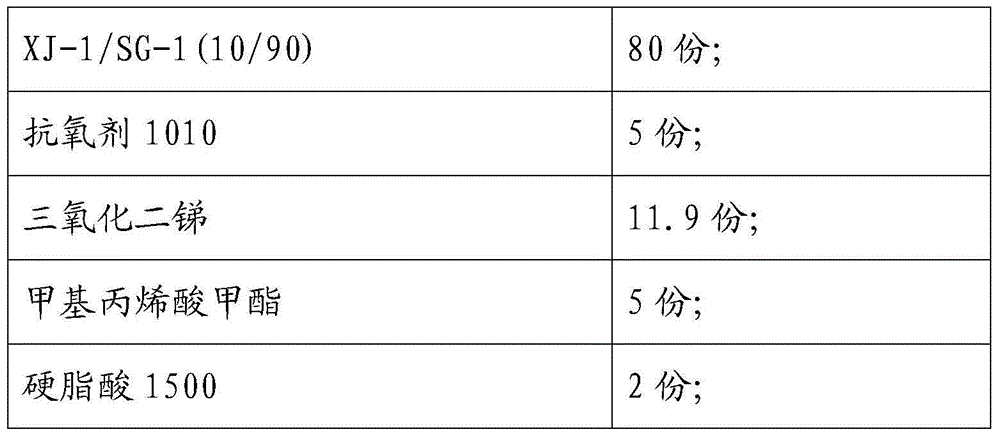

[0038] Embodiment 2, PVC flame-retardant fire-fighting threading pipe 2#

[0039] XJ-1 / SG-3(25 / 75)

Embodiment 3

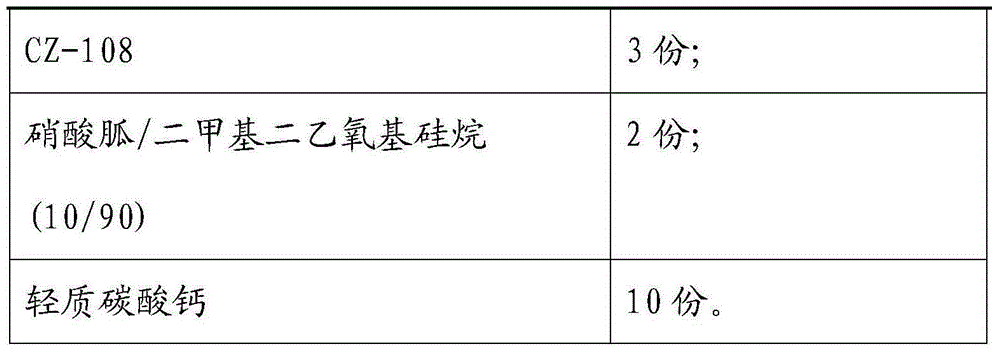

[0040] Embodiment 3, PVC flame-retardant fire-fighting threading pipe 3#

[0041]

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a PVC flame-retardant fire-protection threading pipe. The pipe is characterized by being prepared from the following components in parts by mass: 80 to 90 parts of polyvinyl chloride resin, 2 to 5 parts of an antioxidant, 11 to 15 parts of a flame retardant, 2 to 5 parts of a reinforcing agent, 0.5 to 2 parts of a lubricant, 2 to 3 parts of a stabilizer, 1 to 2 parts of a processing auxiliary agent and 5 to 10 parts of lightweight calcium carbonate. According to performance selection of a PVC resin material, through addition of additives, high-speed hot mixing and twin-screw extrusion molding, the prepared PVC flame-retardant fire-protection threading pipe provided by the invention has a smoke density grade of above 40, and is applicable to straight conduits for protection of wires and cables with 2000V in industrial and building projects.

Description

technical field [0001] The invention relates to the field of PVC pipes, in particular to a PVC flame-retardant fire-fighting threading pipe. Background technique [0002] At present, many users basically use ordinary flame-retardant PVC threading pipes in their buildings to protect all strong and weak current lines such as network lines, telephone lines, and alarm lines. However, most flame-retardant PVC threading pipes are not flame-retardant or even combustion-supporting. In the event of an electrical line fire, the "flame retardant line" is ignited and releases a large amount of toxic gas and smoke, which will cause a very unfavorable situation for personnel evacuation and rescue, and will cause greater fire safety hazards. [0003] For the existing flame-retardant PVC threading pipes, the Ministry of Public Security’s standard requires higher combustion performance for this type of product, while the Ministry of Construction’s standard requires much lower requirements. E...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08L83/04C08K13/02C08K3/26C08K3/22C08K5/098C08K3/32C08K5/053

Inventor 潘心争俞良

Owner SHANGHAI SHANGSU HLDG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com