Formula of degradable antibacterial thin film master batch and production method thereof

A production method and masterbatch technology, applied in the field of medical supplies, can solve problems such as poor heat sealability, and achieve the effects of enhanced flexibility, easy degradation, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

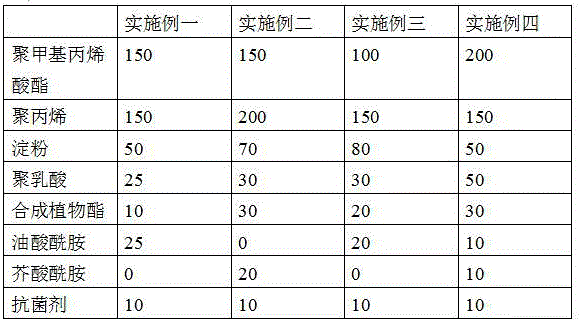

[0024] A kind of solution film masterbatch formula that can reduce antibacterial, comprises the component composition of following parts by weight:

[0025] Polyacrylate: 100~200 parts;

[0026] Polypropylene: 150~300 parts;

[0027] Starch: 50~100 parts;

[0028] Polylactic acid: 20~50 parts;

[0029] Slippery agent: 20~30 parts;

[0030] Antibacterial agent: 5~15 parts;

[0031] Synthetic vegetable ester: 5~50 parts.

[0032] The molecular weight of the starch is 10000-17000.

[0033] In the present invention, polyacrylate and polypropylene are selected as the base material, and through the addition of starch and polylactic acid, when polyacrylate and polypropylene are aggregated together, starch and polylactic acid are aggregated together in the middle. . At the same time, polypropylene and polyacrylate have good compatibility, so the two can be well mixed together during the blending process. At the same time, polyacrylates have carboxyl groups, while starch and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com